Monolithic cluster alumina supported catalyst and application thereof

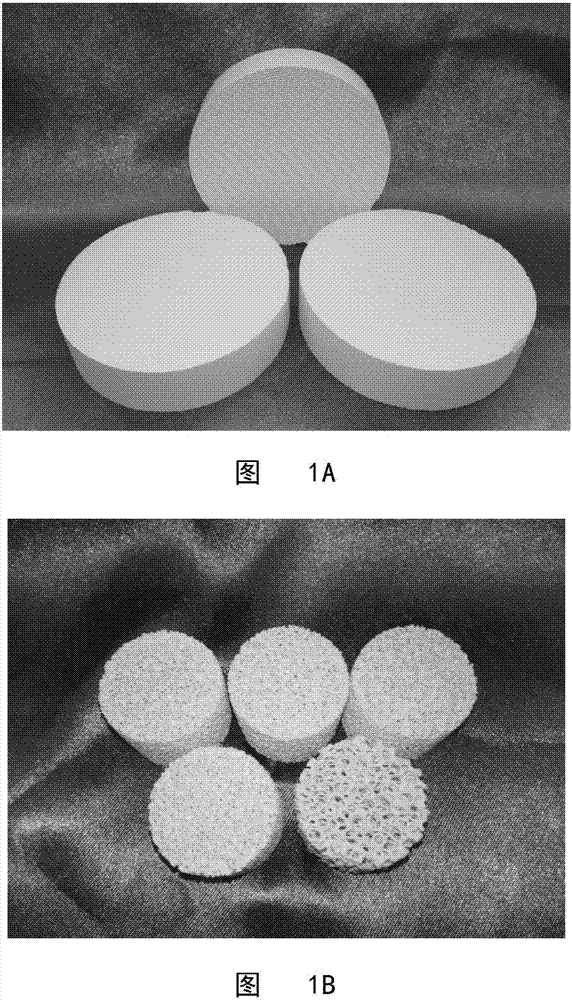

A kind of alumina carrier, monolithic technology, applied in the direction of physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, catalyst carrier, etc., can solve the problem that the original shape cannot be maintained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

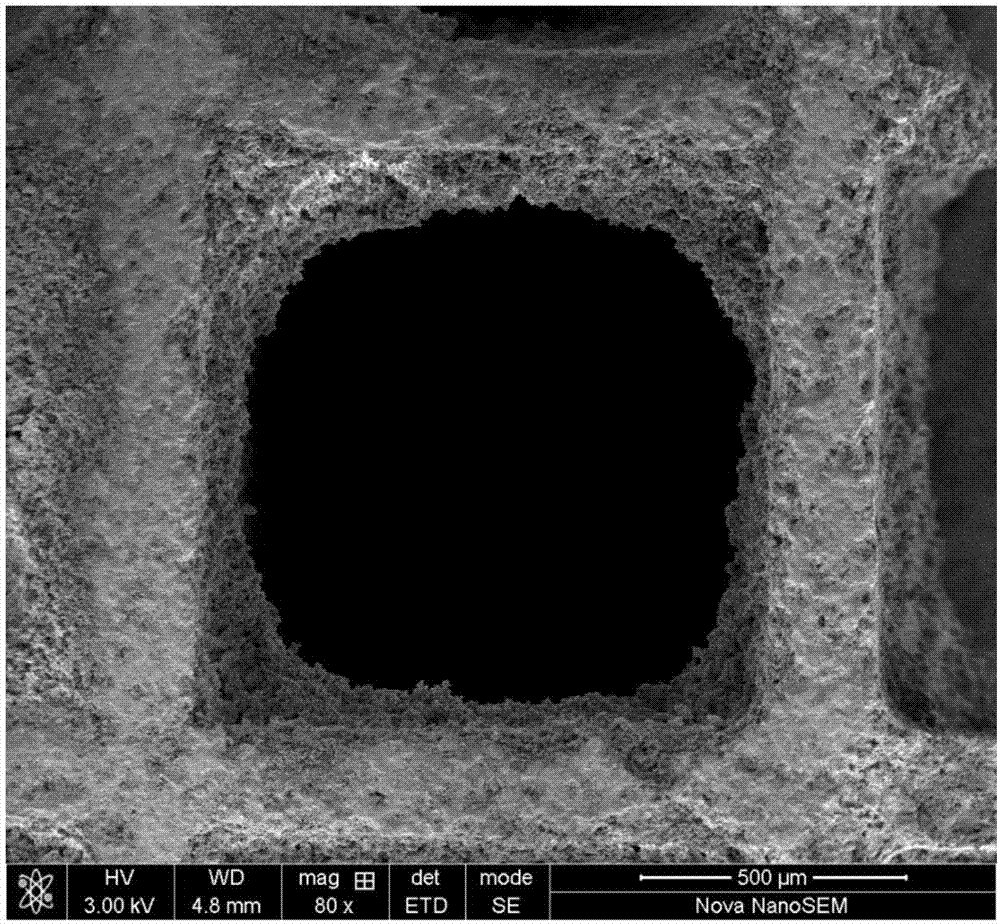

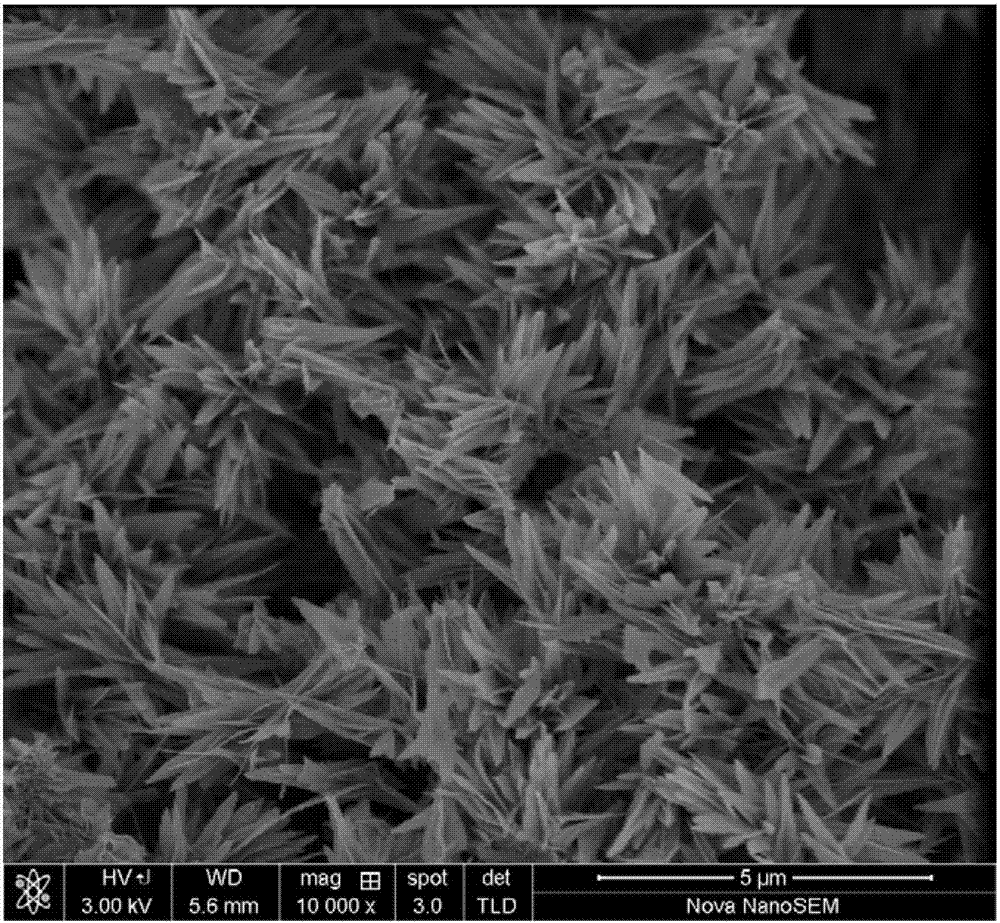

[0080] Take a commercially available cordierite honeycomb ceramic with a pore density of 400psi, cut it into a substrate with a size of 1.0cm×1.0cm×2.5cm, and weigh 1.175g, immerse it in a 50wt% nitric acid solution, and perform pretreatment at 30°C for 24h , washed and dried, and then baked at 1200°C for 6h. Weigh aluminum nitrate (Al(NO 3 ) 3 9H 2 (2) 0.1mol and urea 1.0mol are placed in a beaker, add deionized water and absolute ethanol at room temperature, so that the volume ratio of ethanol and water in the solution is 20:1, and the molar concentration of aluminum ions is 4mol / L, stir Until the solids are all dissolved, move the solution into a high-pressure hydrothermal kettle, and immerse it into the pretreated cordierite honeycomb ceramic matrix. The volume ratio of the solution to the ceramic matrix is 10:1, and the pH is adjusted with ammonia water (weight concentration: 25%) value to neutral, then seal the hydrothermal kettle. Put the hydrothermal kettle in a ...

Embodiment 2

[0082] Take a commercially available mullite honeycomb ceramic with a pore density of 600cpsi, cut it into a matrix with a size of 1.0cm×1.0cm×2.5cm, and weigh 0.975g, and immerse it in a 20wt% oxalic acid solution at 50°C for 10h , washed and dried, and baked at 1200°C for 6h. Weigh aluminum nitrate (Al(NO 3 ) 3 9H 2 (2) 0.3mol, urea 3.0mol are placed in the beaker, add deionized water and dehydrated alcohol at room temperature, make the volume ratio of ethanol and water in the solution be 10:1, the molar concentration of aluminum ion is 0.24mol / L, Stir until the solids are completely dissolved, move the solution into a high-pressure hydrothermal kettle, and immerse it into the pretreated cordierite honeycomb ceramic matrix. The volume ratio of the solution to the ceramic matrix is 50:1, and the solution is adjusted with ammonia water (weight concentration: 25%) pH to neutral, then seal the hydrothermal kettle. The hydrothermal kettle was placed in a thermostat and heat...

Embodiment 3

[0084] Take a commercially available cordierite honeycomb ceramic with a pore density of 400cpsi, cut it into a matrix with a size of 1.0cm×1.0cm×2.5cm, and weigh 1.175g, and immerse it in a 30wt% hydrochloric acid solution at 95°C for 1 hour. Wash and dry, and bake at 1200°C for 6h. Weigh aluminum nitrate (Al(NO 3 ) 3 9H 2 (2) 0.5mol, 5.0mol of urea are placed in the beaker, add deionized water and absolute ethanol at room temperature, make the volume ratio of ethanol and water in the solution be 5:1, the molar concentration of aluminum ion is 10mol / L, stir Until the solids are all dissolved, move the solution into a high-pressure hydrothermal kettle and immerse it into the pretreated cordierite honeycomb ceramic substrate. The volume ratio of the solution to the ceramic substrate is 20:1, and the pH is adjusted with ammonia water (weight concentration: 25%) value to neutral, then seal the hydrothermal kettle. The hydrothermal kettle was placed in a thermostat and heated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com