Novel steel-structure waterborne antirust paint based on rust and application method of novel steel-structure waterborne antirust paint

A rust-proof, steel structure technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of waste of resources, large VOC, unsafe, etc., and achieve the effect of reducing holes and defects, enhancing anti-corrosion ability, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

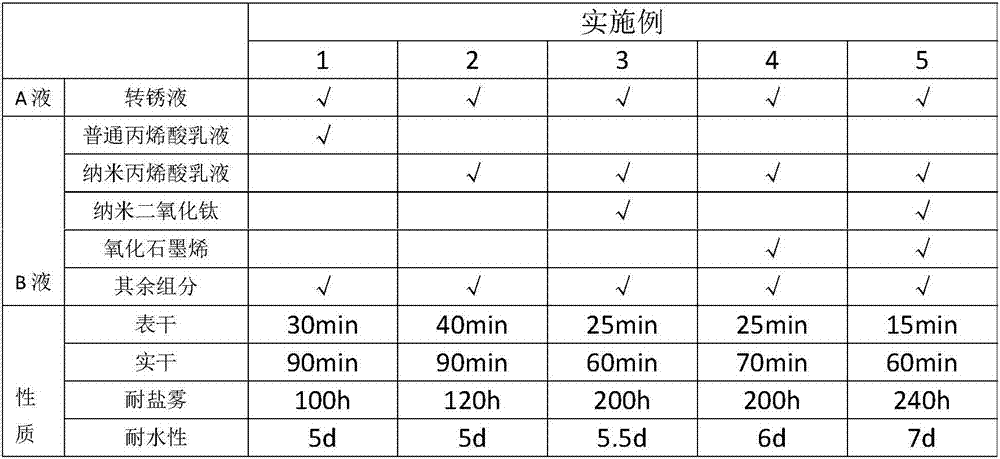

Embodiment 1

[0018] Ordinary acrylic emulsion 65g, the remaining components of liquid B are: film-forming aid 7g, antifreeze agent 0.5g, defoamer 0.3g, wetting agent 0.3g, dispersant 2g, antirust filler 5g, antirust pigment 5g, constitution Filler 10g, thickener 0.3g and deionized water 5g;

Embodiment 2

[0020] Nano acrylic acid emulsion 65g, all the other components of B liquid are the same as embodiment 1;

Embodiment 3

[0022] Nano acrylic acid emulsion 65g, nano titanium dioxide 0.2g, B liquid all the other components are with embodiment 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com