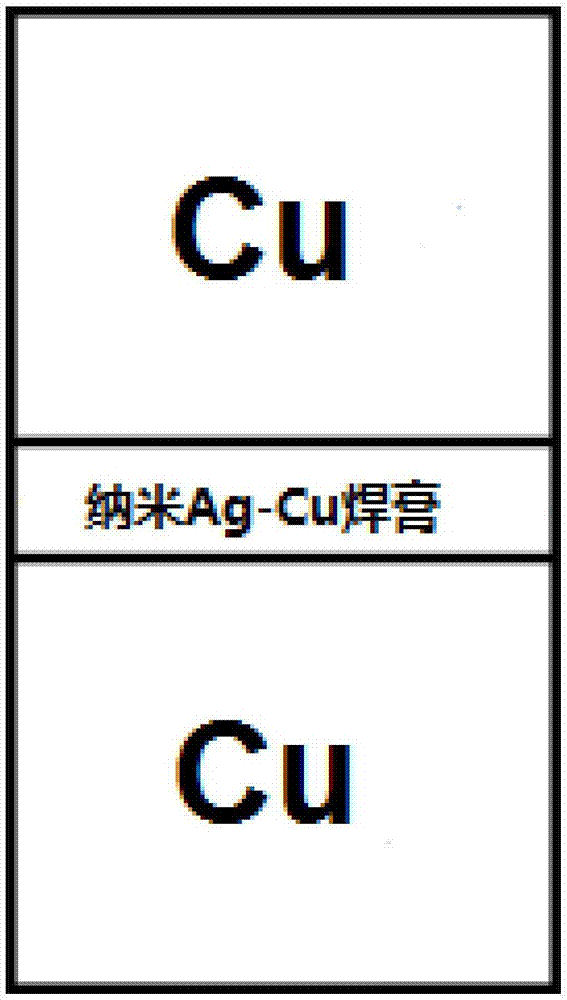

Micro Ag-Cu solder cream, preparing method thereof and application

A nano-solder paste technology, applied in the field of nano-Ag-Cu solder paste and its preparation, can solve problems such as poor resistance to electrochemical migration, damage to substrates and related components, and difficult connections, achieving excellent oxidation resistance and low production costs Low, combined with good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of nanometer Ag-Cu solder paste, concrete steps are as follows:

[0039] 1. Preparation of Ag powder (nano-silver particles with a particle size of 5-10nm):

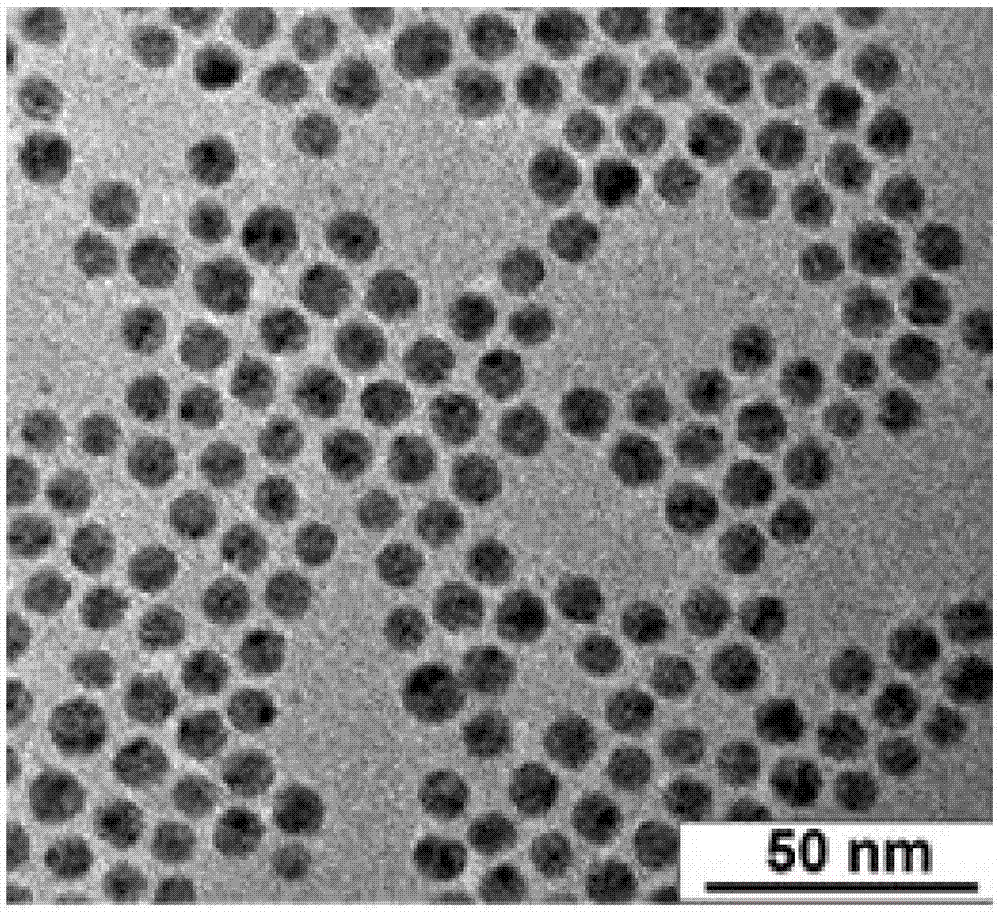

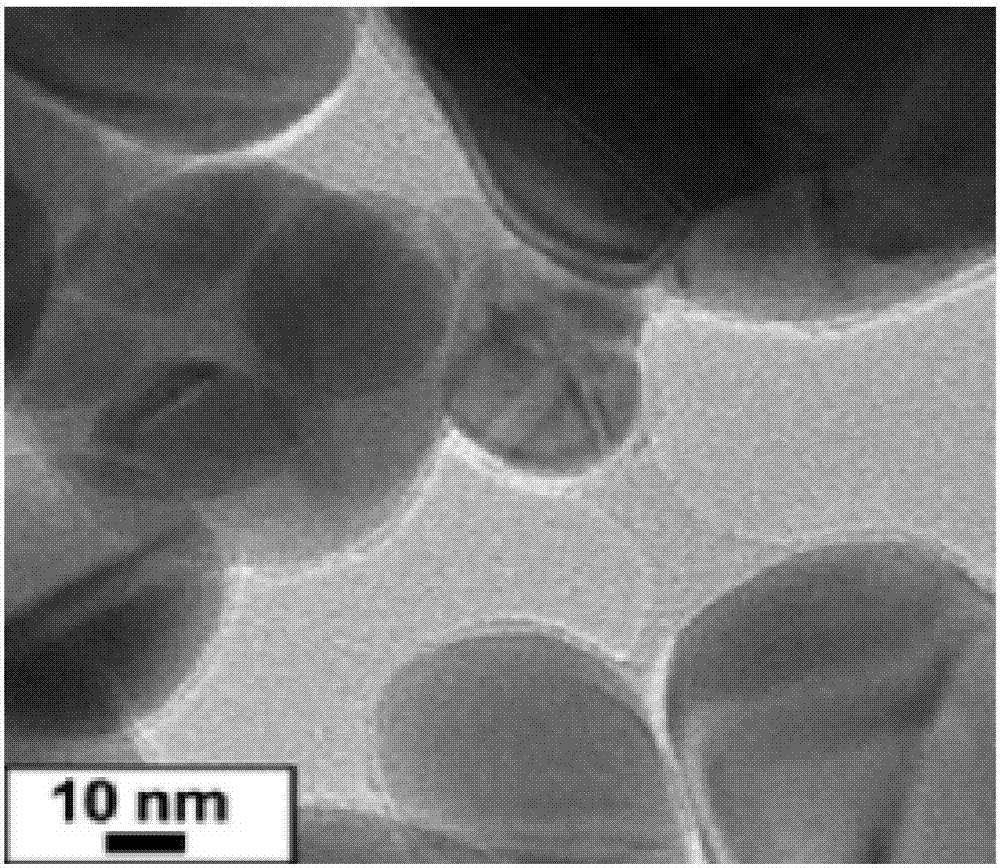

[0040] First, 0.6 g of sodium hydroxide and 4.65 g of stearic acid were dissolved in 600 mL of deionized water, heated to 80 °C, and 2.5 g of AgNO 3 , after constant temperature stirring for 1 h, take the white waxy substance in the upper layer and wash it by centrifugation at a centrifugal rate of 7000 r / min, and wash it 4 times (3 times with deionized water and 1 time with alcohol), and the washing time is 10 min each time. Subsequently, the white waxy substance was heated in a tube furnace with nitrogen gas, the heating rate of the tube furnace was 5°C / min, and when it was heated to 250°C, it was kept for 90 minutes, and finally silver nanoparticles with a particle size of 5-10nm were obtained. . figure 2 It is the SEM image of the silver nano particles prepared in this embodiment.

[0041] ...

Embodiment 2

[0046] The preparation of nanometer Ag-Cu solder paste, concrete steps are as follows:

[0047] Step 1, 2 are with embodiment 1;

[0048] Step 3, preparation of nano-Ag-Cu solder paste: the nano-Ag powder with a particle size of 5-10nm and the nano-Cu powder with a particle size of 20-60nm obtained in steps 1 and 2 respectively in a mass ratio of 4:1 Mix, add alcohol and grind until the alcohol is completely volatilized to obtain uniformly mixed nano Ag-Cu powder, then add glycerol whose mass is one-eighth of the total mass of nano Ag-Cu powder, and make a viscous paste to obtain nano Ag -Cu solder paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com