Preparation method of high-purity MoAlB ceramic powder and compact block body

A ceramic powder, high-purity technology, applied in the field of ceramic material preparation, can solve the problems of long synthesis time, low efficiency, time-consuming and energy-consuming, etc., and achieve the effects of improving purity, simple process flow, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

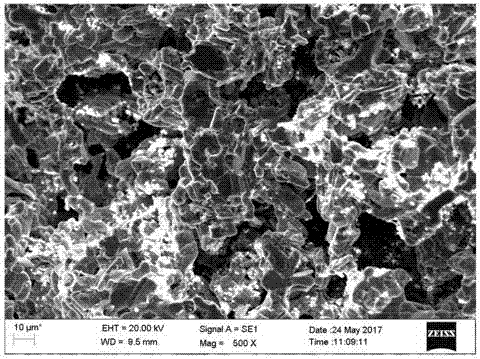

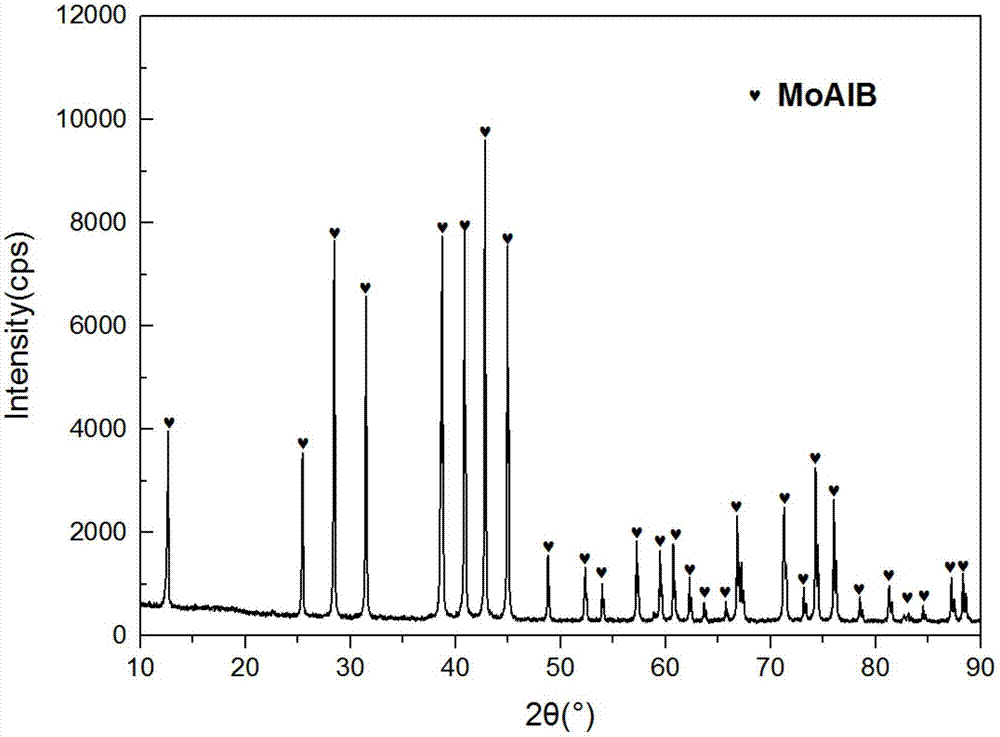

[0024] According to the molar ratio of Mo:Al:B=1:1.1:1, weigh 14.06 grams of Mo powder, 4.35 grams of Al powder, and 1.59 grams of B powder. The above-mentioned ingredients were put into a ball mill jar and mixed for 5 hours. The uniformly mixed ingredients are put into stainless steel molds and compacted on a tablet press. Put the above blank into a graphite mold, place the graphite mold in a vacuum sintering furnace, and raise the temperature of the furnace to 1000°C at a heating rate of 10°C / min under an argon atmosphere, hold the temperature for 120 minutes, and then lower it to room temperature. A high-purity MoAlB material can be obtained. The above-mentioned MoAlB material is pulverized in a ball mill and passed through sieves of different meshes to obtain MoAlB powders with different particle sizes. Carry out X-ray diffraction analysis to the sample obtained, its XRD diffraction pattern sees attached figure 1 , it can be seen from the XRD results that a high-purity ...

Embodiment approach 2

[0026] According to the molar ratio of Mo:Al:B=1:1.1:1, weigh 14.06 grams of Mo powder, 4.35 grams of Al powder, and 1.59 grams of B powder. The above-mentioned ingredients were put into a ball mill jar and mixed for 10 hours. Put the uniformly mixed ingredients into a stainless steel mold and compact it on a tablet press, put the above green body into a graphite mold, place the graphite mold in a vacuum sintering furnace, and heat up at a rate of 20°C / min under an argon atmosphere. Raise the furnace temperature to 1100°C, hold the temperature for 90 minutes, and then lower it to room temperature to obtain high-purity MoAlB material. The above-mentioned MoAlB material is pulverized in a ball mill and passed through sieves of different meshes to obtain MoAlB powders with different particle sizes. The obtained sample was subjected to X-ray diffraction analysis, and the XRD result was the same as that of Embodiment 1.

Embodiment approach 3

[0028] According to the molar ratio of Mo:Al:B=1:1.3:1, weigh 13.53 grams of Mo powder, 4.95 grams of Al powder, and 1.52 grams of B powder. The above-mentioned ingredients were put into a ball mill jar and mixed for 24 hours. Put the uniformly mixed ingredients into a stainless steel mold and compact it on a tablet press, put the above green body into a graphite mold, put the graphite mold in a vacuum sintering furnace, and heat up at a rate of 30°C / min under an argon atmosphere. Raise the furnace temperature to 1200°C, hold the temperature for 60 minutes, and then lower it to room temperature to obtain high-purity MoAlB material. The above-mentioned MoAlB material is pulverized in a ball mill and passed through sieves of different meshes to obtain MoAlB powders with different particle sizes. The obtained sample was subjected to X-ray diffraction analysis, and the XRD result was the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com