Polymer cement waterproof coating

A technology of waterproof coatings and polymers, applied in cement coatings, coatings, etc., can solve problems such as poor mechanical properties and waterproof performance, long storage time, and performance degradation, and achieve improved storage stability, increased large molecular weight substances, The effect of improving the mechanical properties and water resistance of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

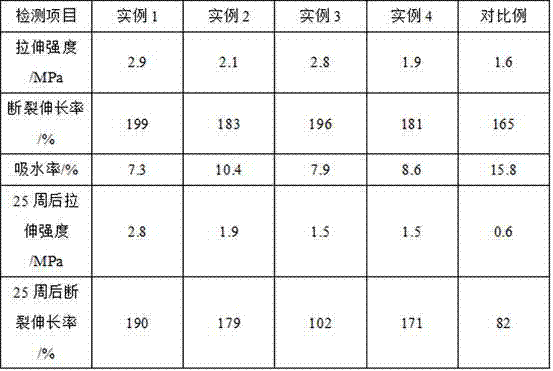

Examples

example 1

[0023]Add acrylic acid and water into a three-necked flask at a mass ratio of 1:30, adjust the pH to neutral with 15% sodium bicarbonate, then add butyl acrylate 1.2 times the mass of acrylic acid and styrene 0.4 times the mass of acrylic acid, and Add potassium persulfate 0.08 times the mass of styrene, and then move the three-necked flask into a digital display velocity measuring constant temperature magnetic stirrer, under the conditions of temperature 80°C and rotation speed 600r / min, stir and react at constant temperature for 6 hours, stop stirring, and Under the condition of 70°C, heat preservation and aging for 3 hours, filter to obtain the filtrate, which is styrene-butyl acrylate-acrylic acid copolymer emulsion; mix chitosan and water at a mass ratio of 1:50, pour it into a beaker, and stir it with a glass rod After mixing for 10 minutes, let stand to swell for 4 hours, then add chitosanase with 0.08 times the mass of chitosan to the beaker, and move the beaker into a ...

example 2

[0025] Add acrylic acid and water into a three-necked flask at a mass ratio of 1:30, adjust the pH to neutral with 15% sodium bicarbonate, then add butyl acrylate 1.2 times the mass of acrylic acid and styrene 0.4 times the mass of acrylic acid, and Add potassium persulfate 0.08 times the mass of styrene, and then move the three-necked flask into a digital display velocity measuring constant temperature magnetic stirrer, under the conditions of temperature 80°C and rotation speed 600r / min, stir and react at constant temperature for 6 hours, stop stirring, and Under the condition of 70°C, heat preservation and aging for 3 hours, filter to obtain the filtrate, which is styrene-butyl acrylate-acrylic acid copolymer emulsion; mix chitosan and water at a mass ratio of 1:50, pour it into a beaker, and stir it with a glass rod After mixing for 10 minutes, let stand to swell for 4 hours, then add chitosanase with 0.08 times the mass of chitosan to the beaker, and move the beaker into a...

example 3

[0027] Add acrylic acid and water into a three-necked flask at a mass ratio of 1:30, adjust the pH to neutral with 15% sodium bicarbonate, then add butyl acrylate 1.2 times the mass of acrylic acid and styrene 0.4 times the mass of acrylic acid, and Add potassium persulfate 0.08 times the mass of styrene, and then move the three-necked flask into a digital display velocity measuring constant temperature magnetic stirrer, under the conditions of temperature 80°C and rotation speed 600r / min, stir and react at constant temperature for 6 hours, stop stirring, and Under the condition of 70°C, heat preservation and aging for 3 hours, filter to obtain the filtrate, which is styrene-butyl acrylate-acrylic acid copolymer emulsion; mix chitosan and water at a mass ratio of 1:50, pour it into a beaker, and stir it with a glass rod After mixing for 10 minutes, let stand to swell for 4 hours, then add chitosanase with 0.08 times the mass of chitosan to the beaker, and move the beaker into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com