Multi-element anti-oxidation and thermal abrasion resistant high-speed steel

A high-speed steel, anti-oxidation technology, applied in the field of metal material technology and manufacturing, can solve problems such as undiscovered tempering hardening properties, and achieve the effects of avoiding nucleation and growth, avoiding toughness deterioration, and high tempering hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

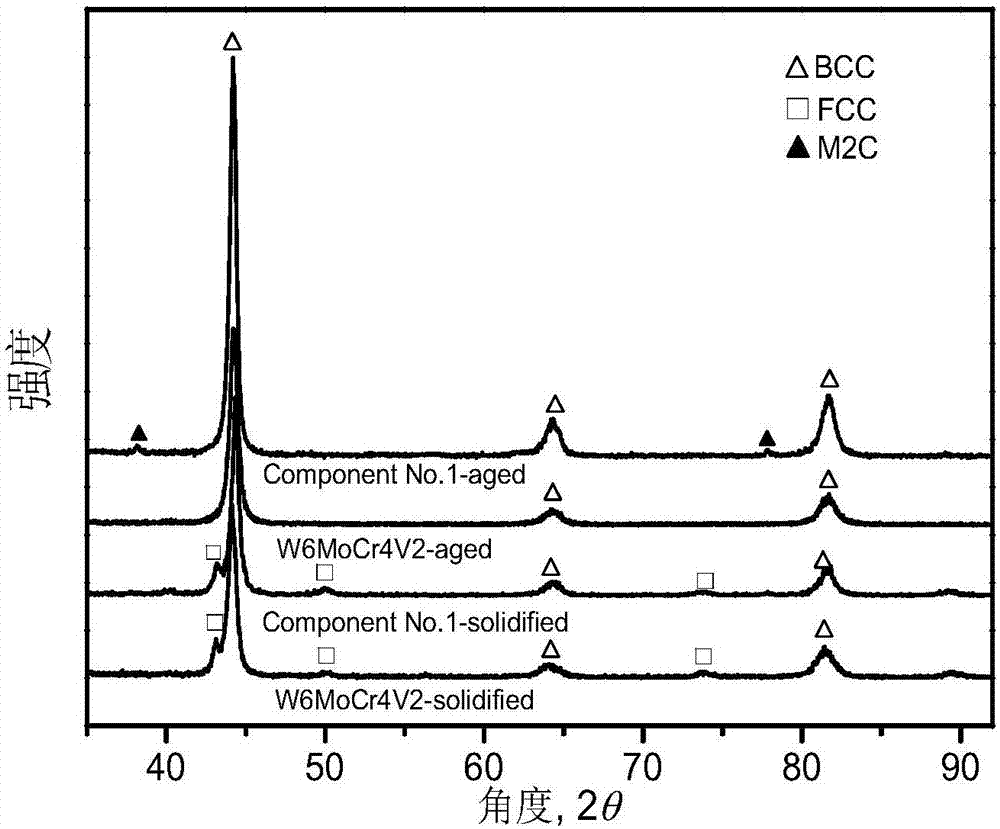

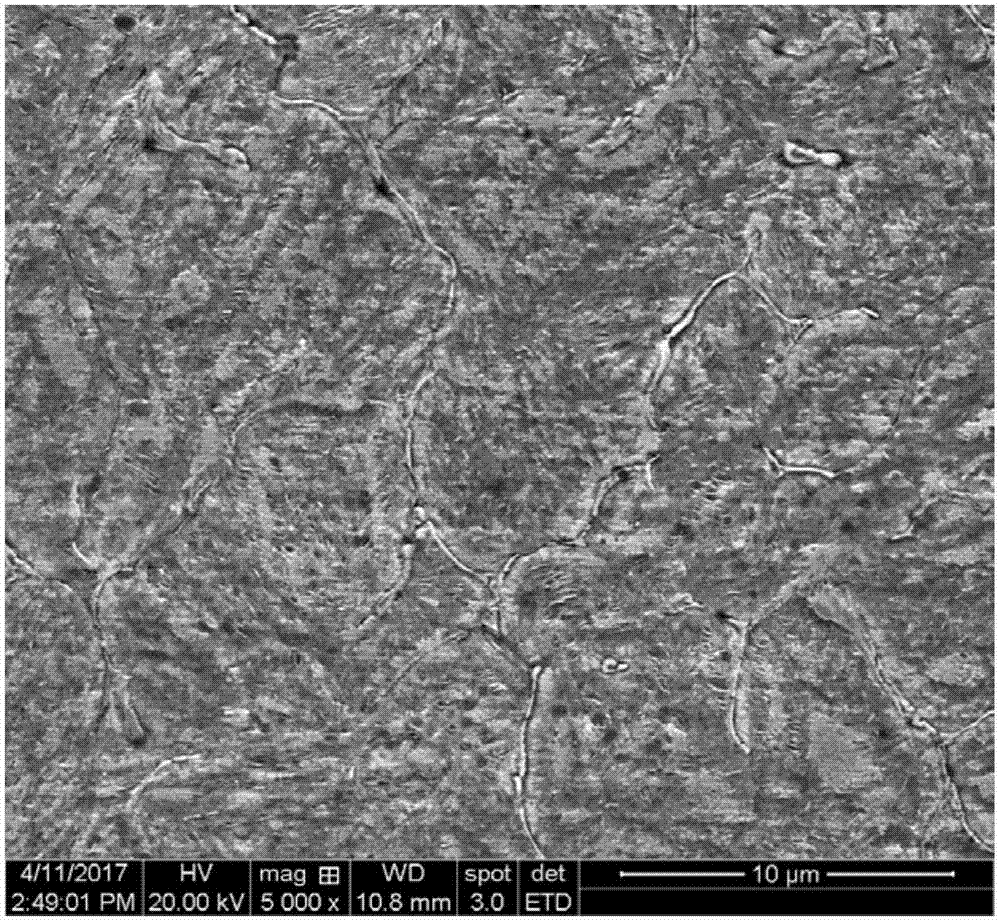

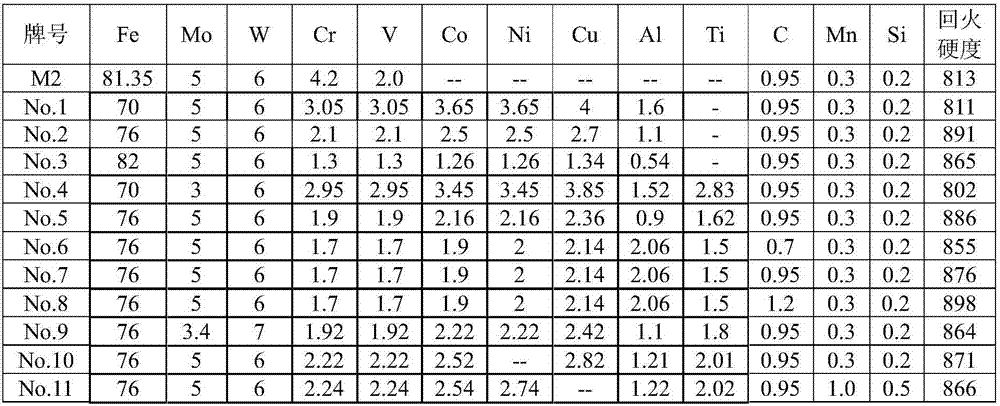

[0018] The M2 grade in the composition list in Table 1 is the typical composition of the commercialized tungsten-molybdenum W6Mo5Cr4V2 high-speed steel, and the components numbered 1 to 11 are the multi-component anti-oxidation, heat-resistant and wear-resistant high-speed steel prepared by laser cladding technology in this example. Among them, the content of matrix Fe element in No. 1-3 is different; No. 4-5 adds Ti alloy element on the basis of No. 1-2; No. 6-8 changes the content of C, and No. 9-11 changes respectively The content of W and Mo or the addition of Ni and Cu elements are selected. Sample preparation process: First, select Fe, Mo, W, Cr, V, Co, Ni, Cu, Al, Ti alloy powders with a purity of ≥99.5% and configure them according to the weight percentage. After configuring the above alloy elements, further Add C, Si, Mn and other elements, in which the contents of S and P elements are all 2 The cross-flow laser cladding the uniformly mixed multi-component high-speed ...

Embodiment 2

[0024] In this example, block high-speed steel was prepared by vacuum electric arc furnace melting and casting technology, and the given components are shown in Table 2. Among them, the grade M2 is a typical composition of tungsten-molybdenum W6Mo5Cr4V2 high-speed steel, and the samples numbered 1 to 4 are the multi-component anti-oxidation, heat-resistant and wear-resistant high-speed steel components prepared by vacuum electric arc furnace melting technology in this embodiment. The selected alloy elements are configured according to weight percentage, and the content of S and P elements in each configuration composition is less than 0.04%, and Si and Mn elements are not added to the composition of this implementation. Sample preparation process: first, cut raw materials from the base metal with a purity of ≥99.5%, and use mechanical grinding to remove the scale on the surface of the raw metal; then, use an electronic balance with an induction capacity of 0.1mg to weigh the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com