Method for reducing histamine content in high-salt liquid-state soy sauce

A technology of high-salt dilute soy sauce and histamine, applied in food science and other directions, can solve the problems of heavy acetic acid taste in Qufang, rust of iron equipment, etc., and achieve the effect of simple operation and green process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) When making koji, after the soybean meal or soybean is cooked at 110°C for 30 minutes, add bran and rice bran in a mass ratio of 1:0.5 and sodium chloride in a ratio of 1:0.02. After mixing, inoculate the soybean meal or soybean mass Using 0.2% Aspergillus oryzae koji essence, making koji at 28°C and 95% humidity for 72 hours to obtain Daqu.

[0019] (2) When Daqu is mixed with brine, add 2.0% ethanol accounting for the total mass ratio of Daqu material and brine, mix well, ferment for 90 days according to the high-salt dilute soy sauce brewing method (GB18186-2000), squeeze and filter to obtain soy sauce crude.

[0020] The content of histamine in soy sauce crude oil was determined according to the method of "Determination of Biogenic Amines in Food Safety National Standard Food" (GB 5009.208-2016).

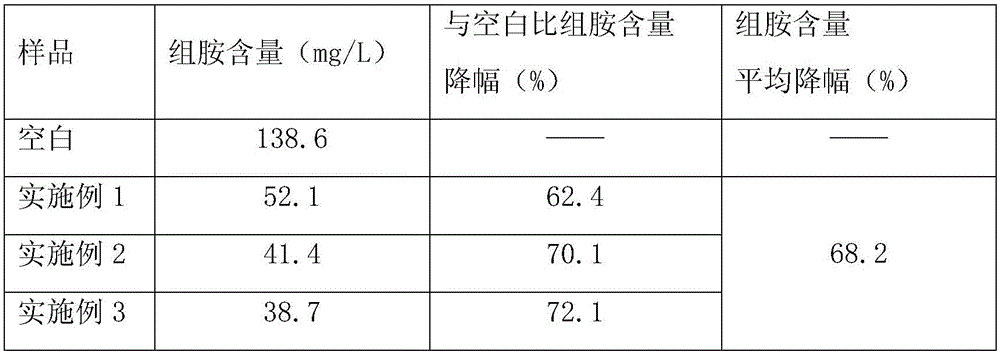

[0021] Table 1 shows the content of histamine in soy sauce crude oil prepared by different fermentation processes.

[0022] Blank in Table 1 is that sodium chloride...

Embodiment 2

[0025] (1) When making koji, after the soybean meal or soybean is cooked at 110°C for 30 minutes, add bran and rice bran in a mass ratio of 1:0.5 and sodium chloride in a ratio of 1:0.03, mix well, and inoculate the mass of soybean meal or soybean Using 0.2% Aspergillus oryzae koji essence, making koji at 28°C and 95% humidity for 72 hours to obtain Daqu.

[0026] (2) When Daqu is mixed with brine, add 3.0% ethanol accounting for the total mass ratio of Daqu material and brine, mix well, ferment for 90 days according to the high-salt dilute soy sauce brewing method (GB18186-2000), squeeze and filter to obtain soy sauce crude.

Embodiment 3

[0028] (1) When making koji, after the soybean meal or soybean is cooked at 110°C for 30 minutes, add bran and rice bran in a mass ratio of 1:0.5 and sodium chloride in a ratio of 1:0.04. After mixing, inoculate the soybean meal or soybean mass Using 0.2% Aspergillus oryzae koji essence, making koji at 28°C and 95% humidity for 72 hours to obtain Daqu.

[0029] (2) When Daqu is mixed with brine, add 4.0% ethanol accounting for the total mass ratio of Daqu material and brine, mix well, ferment for 90 days according to the high-salt dilute soy sauce brewing method (GB18186-2000), squeeze and filter to obtain soy sauce crude.

[0030] Table 1. Histamine content in soy sauce crude oil prepared by different fermentation processes

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com