Furosemide micro-tablet and preparation method thereof

A technology of furosemide microtablets and microtablets, which is applied in the field of preparation of furosemide microtablets, can solve the problems of inability to meet the requirements of individualized medication, inability to conveniently and accurately divide doses, and inability to achieve precise drug administration, so as to ensure Effects of drug efficacy, reduction of adverse reactions, and ease of swallowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

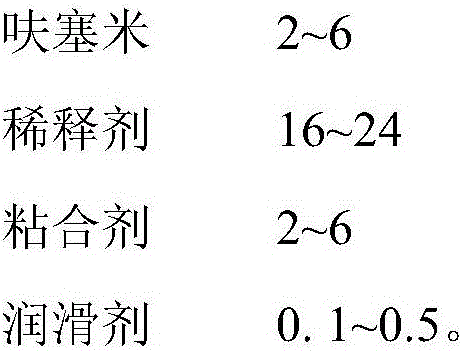

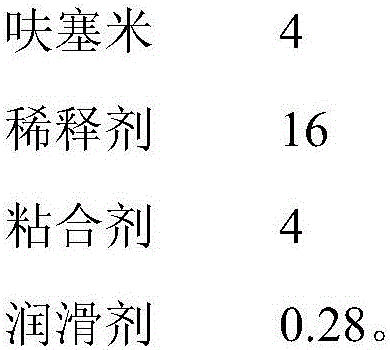

Method used

Image

Examples

Embodiment 1

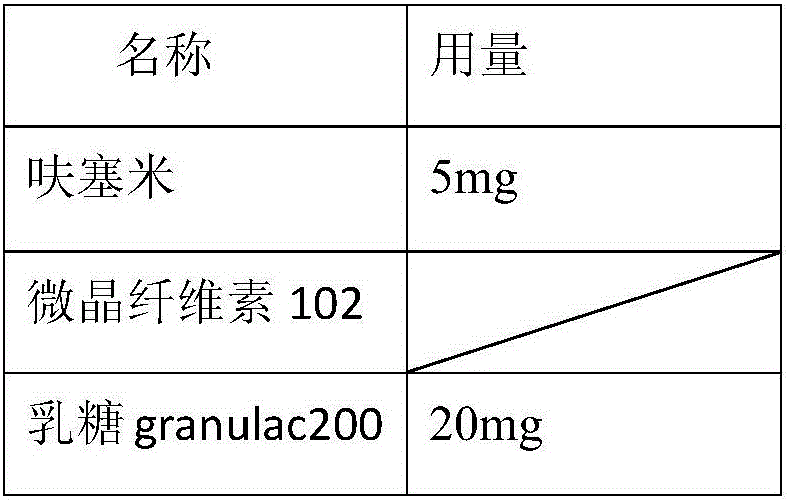

[0024] name

[0025] The preparation process is as follows: put furosemide, microcrystalline cellulose 102, lactose granulac200 and HPMC E3 in a multiphase mixer for uniform mixing, then add magnesium stearate and mix for 3 minutes, transfer the mixed material to high-speed rotary tabletting The tablet is compressed by the machine, and the finished tablet is obtained. The finished furosemide microtablets are obtained.

Embodiment 2

[0027]

[0028]

[0029] The preparation process is as follows: put furosemide, lactose granulac200 and HPMC E3 in the pot of the wet granulator, turn on the paddle for 10 minutes of initial mixing, after the mixing is completed, turn on the paddle and spray purified water for wet granulation; purified water Continue to granulate for 5 minutes after spraying; then wet granules obtained by wet granulation, and then placed in a fluidized bed for drying, after drying, the granules undergo dry granulation; the dry granules are evenly mixed with the prescribed amount of magnesium stearate Finally, the mixed material is transferred to a high-speed rotary tablet press for tablet compression to obtain the finished furosemide microtablet.

Embodiment 3

[0031]

[0032] Preparation process: After mixing furosemide, microcrystalline cellulose 102 and HPMC E3 evenly, the mixed material is added to a dry granulator to obtain suitable dry granules; after the granules are uniformly mixed with magnesium stearate, the mixed material is Transfer to a high-speed rotary tablet press for tablet compression to obtain finished tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com