Blank for ceramic flowerpot

A technology of blanks and flowerpots, which is applied in the field of ceramic manufacturing, can solve the problems of poor plasticity, and achieve the effects of high toughness and firmness, excellent air permeability and water absorption, and high air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

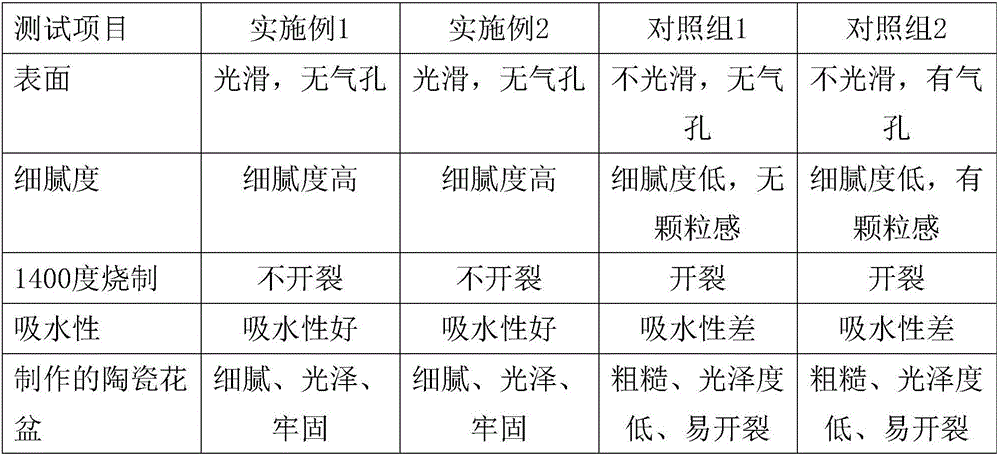

Examples

Embodiment 1

[0023] A blank for ceramic flowerpots, made of the following raw materials in parts by weight:

[0024] 25 parts of volcanic ash, 12 parts of sodium bentonite, 10 parts of bamboo charcoal fiber, 8 parts of activated carbon, 6 parts of phosphate, 5 parts of oxidized polyethylene, 5 parts of nano ceramic powder, 4 parts of adhesive, 3 parts of plasticizer, modifier 4 parts, 1 part paraffin, 5 parts epoxy soybean oil, 1 part nitrile rubber, 80 parts water.

[0025] Further, the improving agent is composed of the following components by weight: 3 parts of potato starch, 3 parts of plant ash, 3 parts of straw, 2 parts of waste paper boxes, 2 parts of cotton, 1 part of sand, 1 part of sulfur, 8 parts of lime water share.

[0026] Its preparation method comprises the following steps:

[0027] (1) Add volcanic ash, sodium bentonite, bamboo charcoal fiber, activated carbon, and nano-ceramic powder to the water, mix well, stir and heat, heat to 90°C and keep it for 10 minutes, add par...

Embodiment 2

[0035] A blank for ceramic flowerpots, made of the following raw materials in parts by weight:

[0036] 30 parts of volcanic ash, 15 parts of sodium bentonite, 15 parts of bamboo charcoal fiber, 11 parts of activated carbon, 10 parts of phosphate, 8 parts of oxidized polyethylene, 8 parts of nano-ceramic powder, 6 parts of adhesive, 5 parts of plasticizer, modifier 6 parts, 3 parts paraffin, 10 parts epoxy soybean oil, 2 parts nitrile rubber, 100 parts water.

[0037] Further, the improver is composed of the following components by weight: 6 parts of potato starch, 6 parts of plant ash, 6 parts of straw, 4 parts of waste paper boxes, 4 parts of cotton, 3 parts of sand, 3 parts of sulfur, 14 parts of lime water .

[0038] Its preparation method comprises the following steps:

[0039] (1) Add volcanic ash, sodium bentonite, bamboo charcoal fiber, activated carbon, and nano-ceramic powder to the water, mix well, stir and heat, heat to 100°C and keep it for 10 minutes, add paraf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com