Method for extracting mulberry bark fibers

A technology of mulberry bark fiber and extraction method, which is applied in the field of fiber production, can solve the problems of poor fiber quality, high consumption, and heavy pollution, and achieve the effects of low cost, reduced harmful pollutants, and low residual glue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Firstly, the mulberry branches are peeled. The mulberry peeling process includes three parts: felling, hammering, and peeling. The required equipment includes sickle and hammer. The stripping time is carried out when fresh mulberry branches, the second step is soaking, peeling, and then degumming. The degumming step is: the degumming bacteria made by the selected degumming bacteria (selected and preserved by the School of Life Science and Technology, Guangxi University) The liquid was inoculated on the mulberry bark (Gui Sangyou No. 12 and No. 62), and the instruments used mainly included SPX-250 biochemical incubator, HQL300A cabinet type refrigerated constant temperature shaker, SW-CJ-1F purification workbench, UV-1601 type UV spectrophotometer, etc. Wherein, the inoculum amount of the degumming solution is 10%.

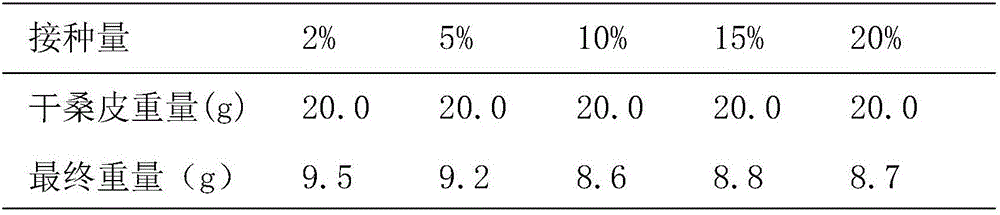

[0018] The effect of different inoculum amounts on degumming was studied, and the results showed that the degumming effect was best when 10% inoculum amoun...

Embodiment 2

[0027] Firstly, the mulberry branches are peeled. The mulberry peeling process includes three parts: felling, hammering, and peeling. The required equipment includes sickle and hammer. The stripping time is carried out when fresh mulberry branches, the second step is soaking, peeling, and then degumming. The degumming step is: the degumming bacteria made by the selected degumming bacteria (selected and preserved by the School of Life Science and Technology, Guangxi University) The liquid was inoculated on the mulberry bark (Gui Sangyou No. 12 and No. 62), and the instruments used mainly included SPX-250 biochemical incubator, HQL300A cabinet type refrigerated constant temperature shaker, SW-CJ-1F purification workbench, UV-1601 type UV spectrophotometer, etc. Wherein, the inoculum amount of the degumming solution is 15%.

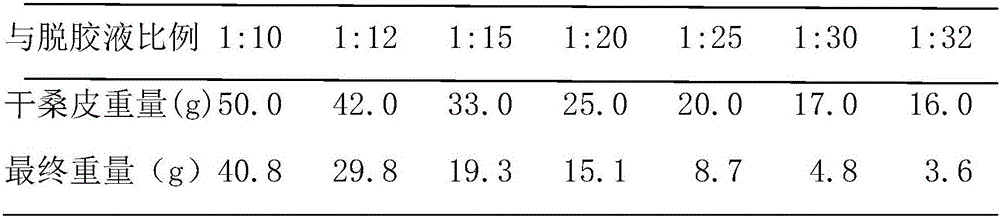

[0028] The ratio of dry mulberry bark to degumming solution is 1:20

[0029] The bath ratio test results of dry mulberry bark and degumming solution are s...

Embodiment 3

[0037] Firstly, the mulberry branches are peeled. The mulberry peeling process includes three parts: felling, hammering, and peeling. The required equipment includes sickle and hammer. The stripping time is carried out when fresh mulberry branches, the second step is soaking, peeling, and then degumming. The degumming step is: the degumming bacteria made by the selected degumming bacteria (selected and preserved by the School of Life Science and Technology, Guangxi University) The liquid was inoculated on the mulberry bark (Gui Sangyou No. 12 and No. 62), and the instruments used mainly included SPX-250 biochemical incubator, HQL300A cabinet type refrigerated constant temperature shaker, SW-CJ-1F purification workbench, UV-1601 type UV spectrophotometer, etc. Wherein, the inoculum amount of the degumming solution is 12%.

[0038] The ratio of dried mulberry bark to degumming solution is 1:23

[0039] The degumming temperature is selected at 36°C

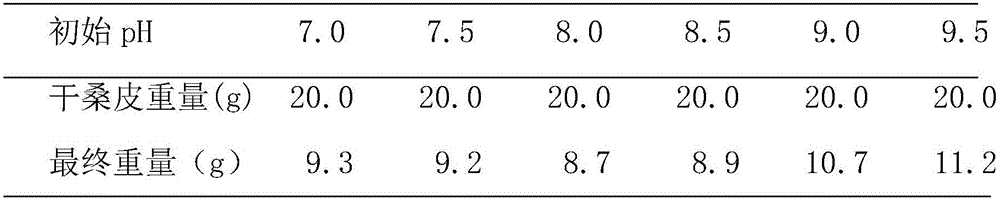

[0040] The pH of the degum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com