Independent circulating filtration temperature-control water-cooling hydraulic system

A technology of hydraulic system and circulating filtration, applied in the direction of fluid pressure actuating system components, fluid pressure actuating devices, servo motors, etc., to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

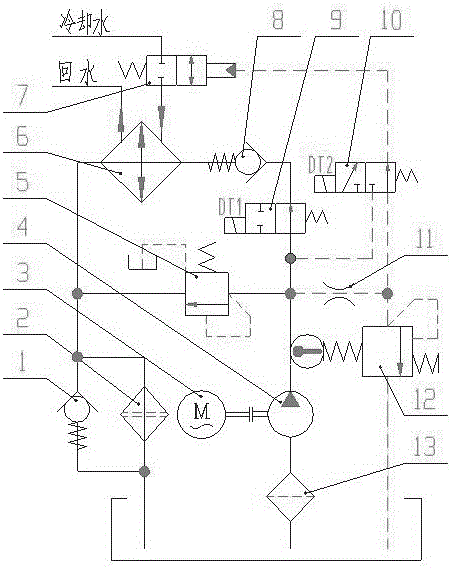

[0020] figure 1 As shown, the specific implementation is as follows:

[0021] An independent circulation filtering temperature-controlled water-cooled hydraulic system, including a motor 3, a hydraulic pump 4 and an oil suction filter 13, the hydraulic pump 4 is connected to the oil tank through the oil suction filter 13, the motor 3 drives the hydraulic pump 4 to work, and the oil output of the hydraulic pump 4 One of the ends of the hydraulic pump 4 passes through the sequence valve 5 and the oil return filter 2 into the oil tank in turn, and the two ends of the oil return filter 2 are connected in parallel with a check valve 1 that is normally unconnected, and one of the oil outlet ends of the hydraulic pump 4 passes through the throttle valve in turn. 11 and thermal relief valve 12 lead into the oil tank so as to automatically detect the oil temperature and automatically adjust the oil inlet pressure of thermal relief valve 12 according to the oil temperature. The valve 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com