Multifunctional fully-automatic blue wafer integrated machine method and apparatus

A blue-model integrated and fully automatic technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of troublesome adjustment, high detection cost, labor and material resources, and achieve safe and reliable use and high automation procedures. , The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

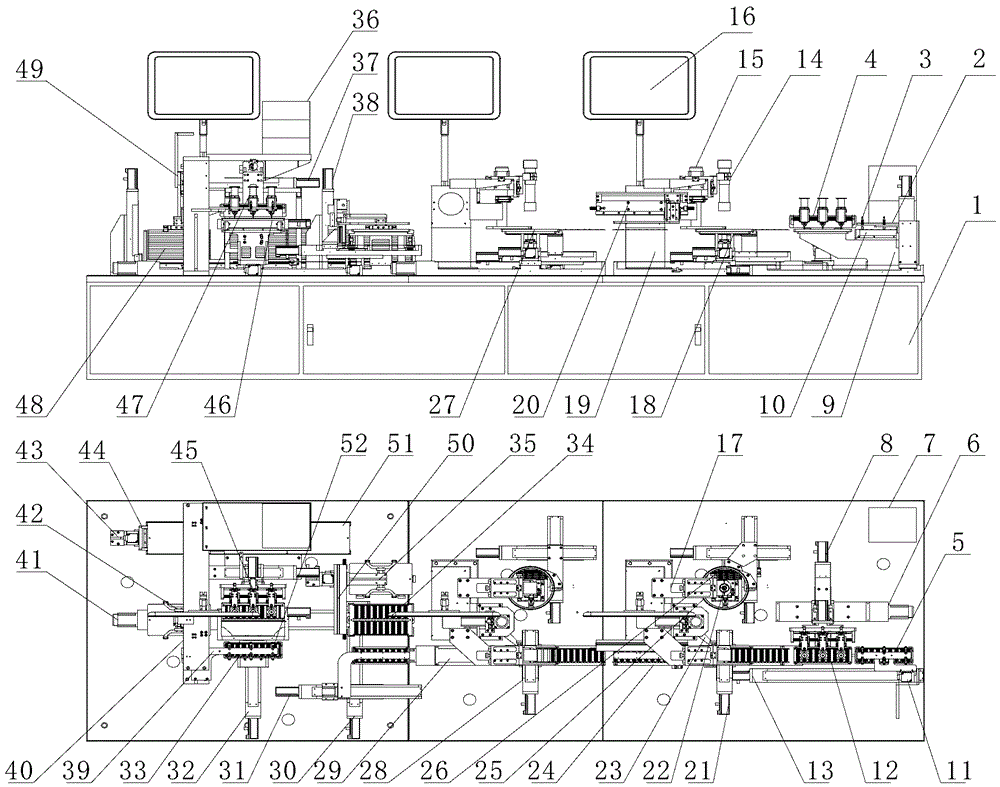

[0014] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

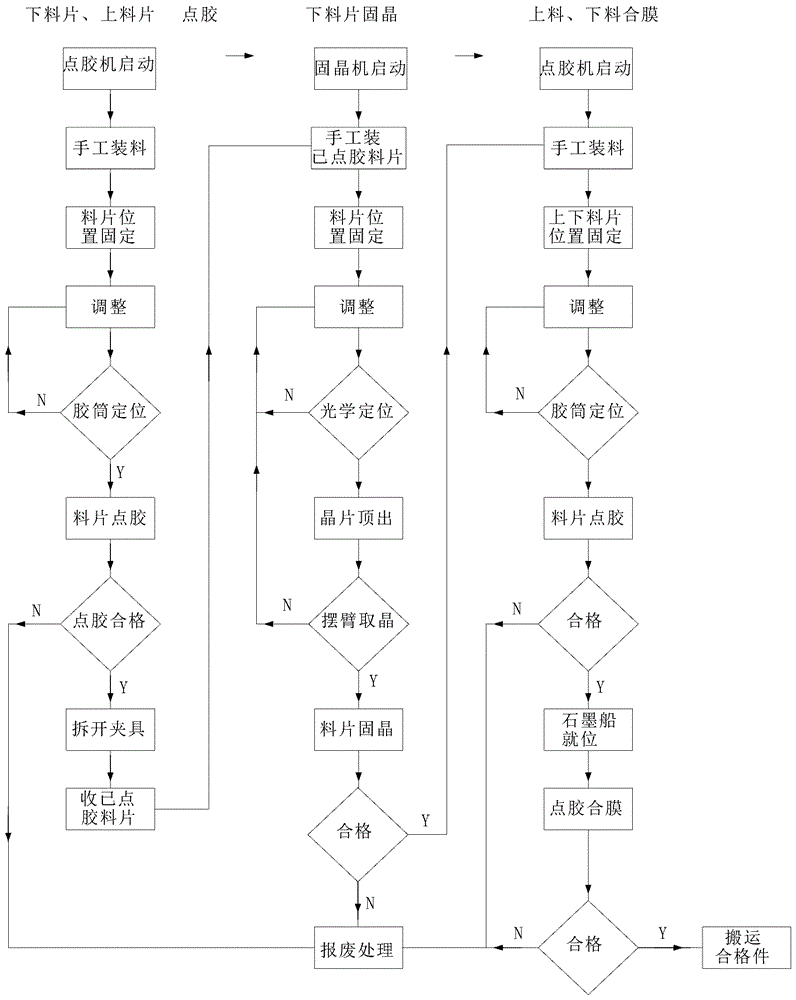

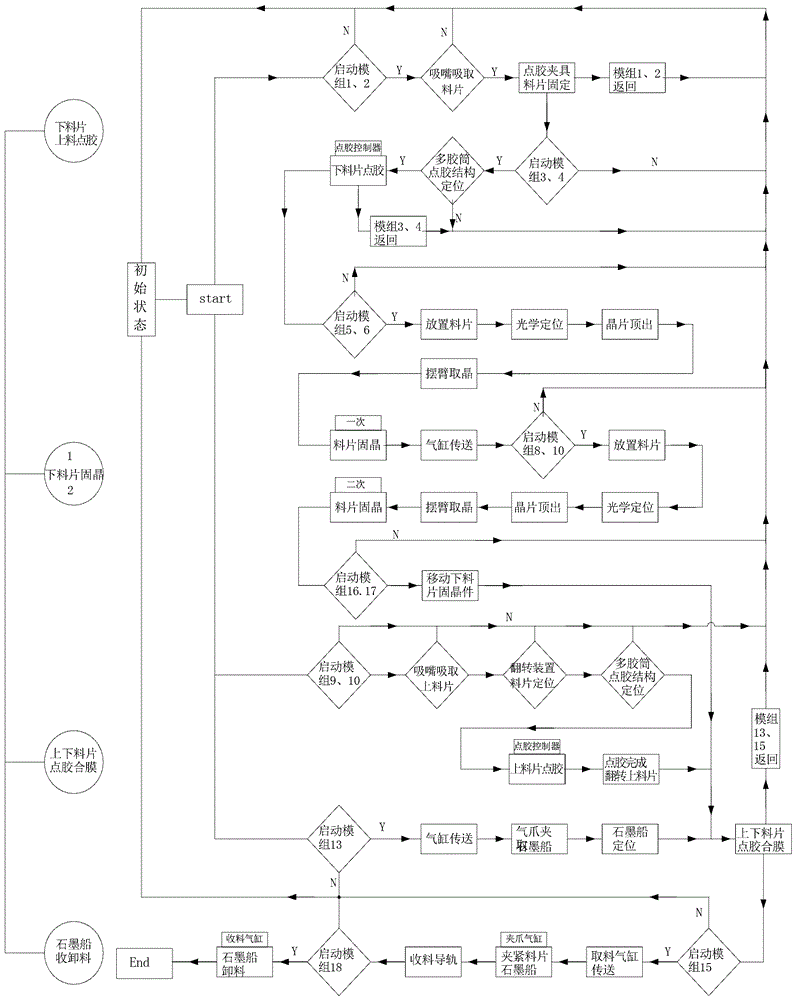

[0015] Such as Figure 2 to Figure 3 The method and device of the present invention shown are a method and device of a multi-functional blue mold all-in-one machine that integrates automatic loading and unloading, glue dispensing, solid crystal, mold closing, etc. The method and device of the all-in-one machine include automatic loading Material device (54), unloading sheet glue dispensing system (55), unloading sheet die-fixing system (56) (57), upper and lower blank dispensing and mold clamping system (58), graphite ship automatic loading and unloading system (59) .

[0016] The present invention comprehensively considers factor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com