Imaging lens

A technology of camera lens and polycarbonate resin, applied in the field of camera lens, can solve the problems of low heat resistance and brittle resin, and achieve the effects of low water absorption, remarkable effect and low birefringence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1~4

[0066] Evaluation was implemented by the following method.

[0067] (1) Specific viscosity: The polycarbonate resin obtained after the polymerization was fully dried, and a solution obtained by dissolving 0.7 g of the pellets in 100 ml of methylene chloride was used to measure the specific viscosity (ηsp) at 20° C. of the solution.

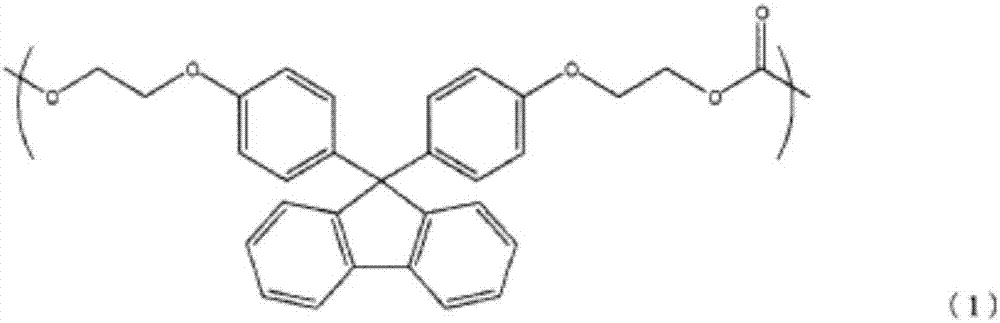

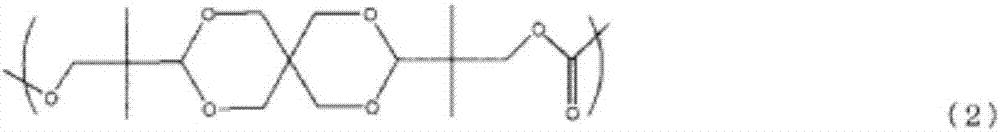

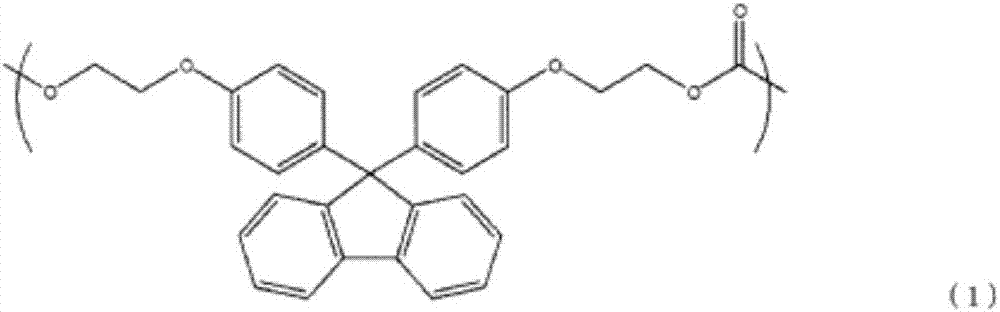

[0068] (2) Copolymerization ratio: measured by proton NMR using JNM-AL400 manufactured by JEOL Ltd. It was determined by the integral ratio of the peak due to the structure of formula (1) around 7.6 to 7.8 ppm and the peak due to the structure of formula (2) around 0.8 to 1.1 ppm.

[0069] (3) Refractive index (nD), Abbe's number (ν): The refractive index at 25° C. was measured on a disc with a thickness of 0.3 mm and a diameter of 5 mm obtained by injection molding using an Abbe refractometer DR-M2 manufactured by ATAGO. The Abbe's number was calculated from the refractive index of measurement wavelength: 486 nm, 589 nm, and 656 nm by the follow...

Embodiment 1

[0086] 110.50 parts of 9,9-bis(4-(2-hydroxyethoxy)phenyl)fluorene (hereinafter, abbreviated as BPEF), 3,9-bis(1,1-dimethyl-2-hydroxyethyl )-2,4,8,10-tetraoxaspiro[5.5]undecane (hereinafter, abbreviated as SPG) 45.05 parts, diphenyl carbonate 87.40 parts, and sodium hydroxide as a catalyst 8.00×10 -5 Parts, Tetramethylammonium Hydroxide 3.65×10 -3 Parts were put into a reaction kettle with a stirrer and a distillation device, and after three times of nitrogen replacement, the jacket was heated to 180°C to melt the raw materials. After complete melting, the jacket was heated up to 260° C. at a rate of 60° C. / hr while depressurizing to 20 kPa over 20 minutes to conduct a transesterification reaction. Thereafter, with the jacket kept at 260°C, the pressure was reduced to 0.13 kPa over 80 minutes, and a polymerization reaction was performed at 260°C and 0.13 kPa or less for 30 minutes. After the reaction, the produced polycarbonate resin is granulated and extracted to obtain poly...

Embodiment 2

[0088]Polycarbonate resin particles were obtained in the same manner as in Example 1 except that BPEF was 105.24 parts and SPG was 48.70 parts. Using these pellets, the measurement was carried out in the same manner as in Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com