Oxygen carrier for chemical looping hydrogen production and its preparation method and application

An oxygen carrier and chemical chain technology, applied in the field of chemical chain hydrogen production, can solve the problems of limited oxygen carrying rate, poor cycle reaction ability, and inability to withstand high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

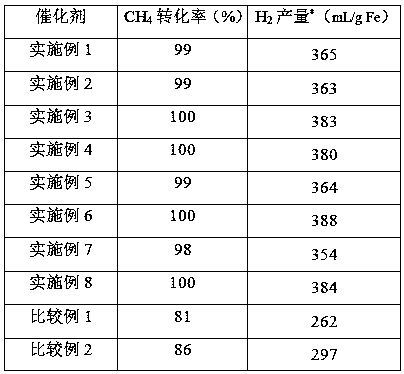

Examples

Embodiment 1

[0028] Weigh 116g, 80~100 mesh Al 2 O 3 The pellets were put into the flask of the rotary evaporator, and the temperature of the water bath was kept at 65°C. Weigh 20g Fe(NO 3 ) 3 ·9H 2 O, 1.3g(NH 4 ) 6 ·Mo 7 O 24 ·4H 2 O, put it into a 500mL beaker, add 100mL deionized water to make a mixed solution, turn on the vacuum pump after dissolving, and suck the mixed solution into the flask. The rotation speed of the flask is 100r / min. After the solution is completely evaporated, remove the Al 2 O 3 The pellets were then dried in a drying oven at 110°C for 24 hours and calcined in a muffle furnace at 900°C for 6 hours to obtain an oxygen carrier Fe 2 O 3 -MoO 3 / Al 2 O 3 , Where Fe 2 O 3 The mass content is 20%, MoO 3 The mass content is 5%, Al 2 O 3 The mass content is 75%.

Embodiment 2

[0030] Weigh 116g, 80~100 mesh Al 2 O 3 The pellets were put into the flask of the rotary evaporator, and the temperature of the water bath was kept at 65°C. Weigh 20g Fe(NO 3 ) 3 ·9H 2 O, 6.7g(NH 4 ) 6 ·Mo 7 O 24 ·4H 2 O, put it into a 500mL beaker, add 100mL deionized water to make a mixed solution, turn on the vacuum pump after dissolving, and suck the mixed solution into the flask. The rotation speed of the flask is 100r / min. After the solution is completely evaporated, remove the Al 2 O 3 The pellets were then dried in a drying oven at 110°C for 24 hours and calcined in a muffle furnace at 900°C for 6 hours to obtain an oxygen carrier Fe 2 O 3 -MoO 3 / Al 2 O 3 , Where Fe 2 O 3 The mass content is 20%, MoO 3 The mass content is 20%, Al 2 O 3 The mass content is 60%.

Embodiment 3

[0032] Weigh 116g, 80~100 mesh Al 2 O 3 The pellets were put into the flask of the rotary evaporator, and the temperature of the water bath was kept at 65°C. Weigh 10g Fe(NO 3 ) 3 ·9H 2 O, 1.05g(NH 4 ) 6 ·Mo 7 O 24 ·4H 2 O, put it into a 500mL beaker, add 100mL deionized water to make a mixed solution, turn on the vacuum pump after dissolving, and suck the mixed solution into the flask. The rotation speed of the flask is 100r / min. After the solution is completely evaporated, remove the Al 2 O 3 The pellets were then dried in a drying oven at 110°C for 24 hours and calcined in a muffle furnace at 900°C for 6 hours to obtain an oxygen carrier Fe 2 O 3 -MoO 3 / Al 2 O 3 , Where Fe 2 O 3 The mass content is 10%, MoO 3 The mass content is 5%, Al 2 O 3 The mass content is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com