Preparing method of graphene powder

A graphene powder and graphite technology, applied in the field of graphene powder preparation, can solve the problems of serious environmental protection burden, high cost and low efficiency, and achieve the effects of reducing industrial cost, complete lattice structure and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) In the Erlenmeyer flask, add 0.1g of graphite, 0.4g of potassium persulfate and 10ml (about 20g) of chlorosulfonic acid in sequence, and stir for 1min to mix evenly; the graphite is natural flake graphite or pyrolytic graphite, and the carbon The content is greater than 90%, the same below.

[0031] 2) Slowly add distilled water dropwise to the system in step 1), and add 1ml of distilled water dropwise in total for reaction, and a mixed solution system is obtained after the reaction is completed;

[0032] 3) Insert the 50W ultrasonic probe into the liquid surface of the mixed solution system obtained in step 2), ultrasonically treat for 2h, wash with distilled water to neutrality, centrifuge at 3000rpm for 10min, remove the unreacted graphite in the lower layer, and collect the wet graphene in the upper layer;

[0033] 4) The wet graphene obtained in step 3) is freeze-dried for 5h to obtain graphene powder.

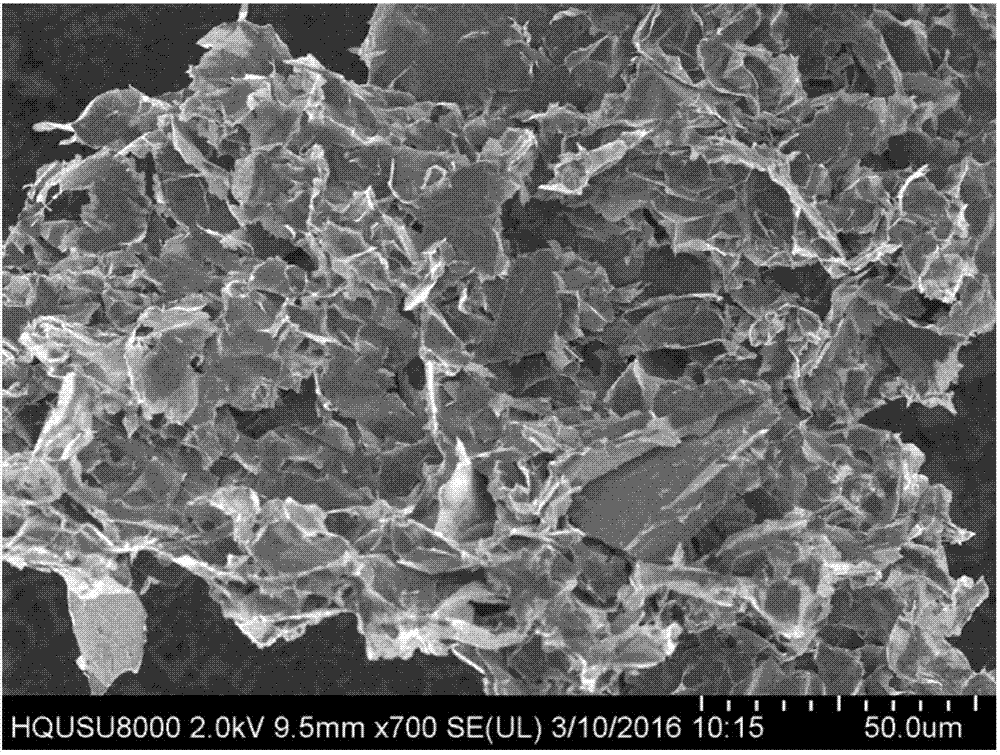

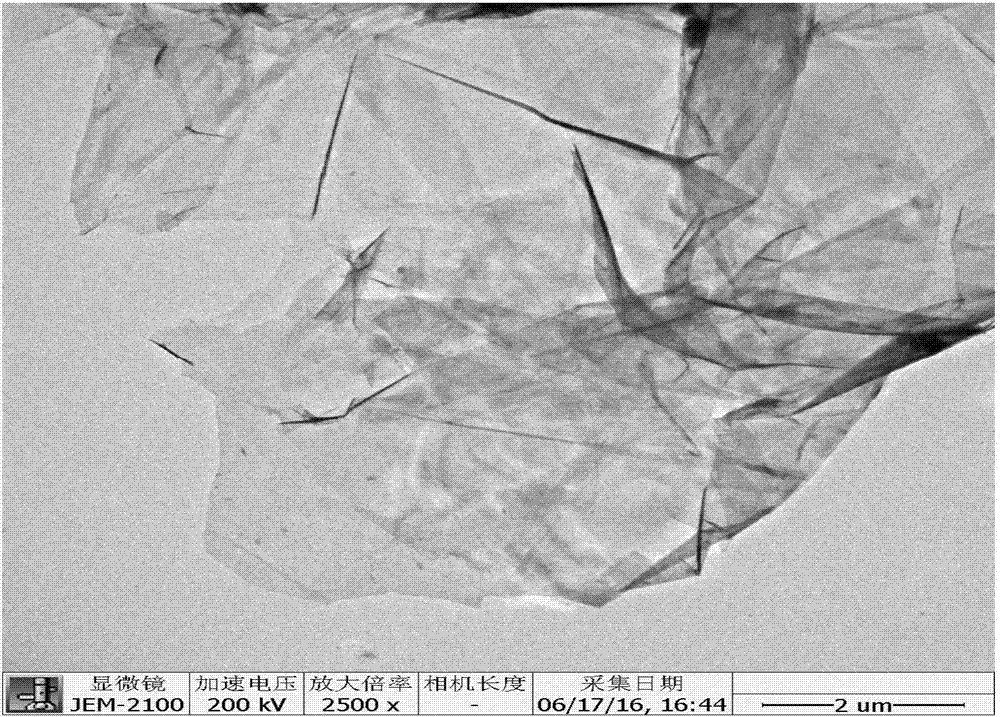

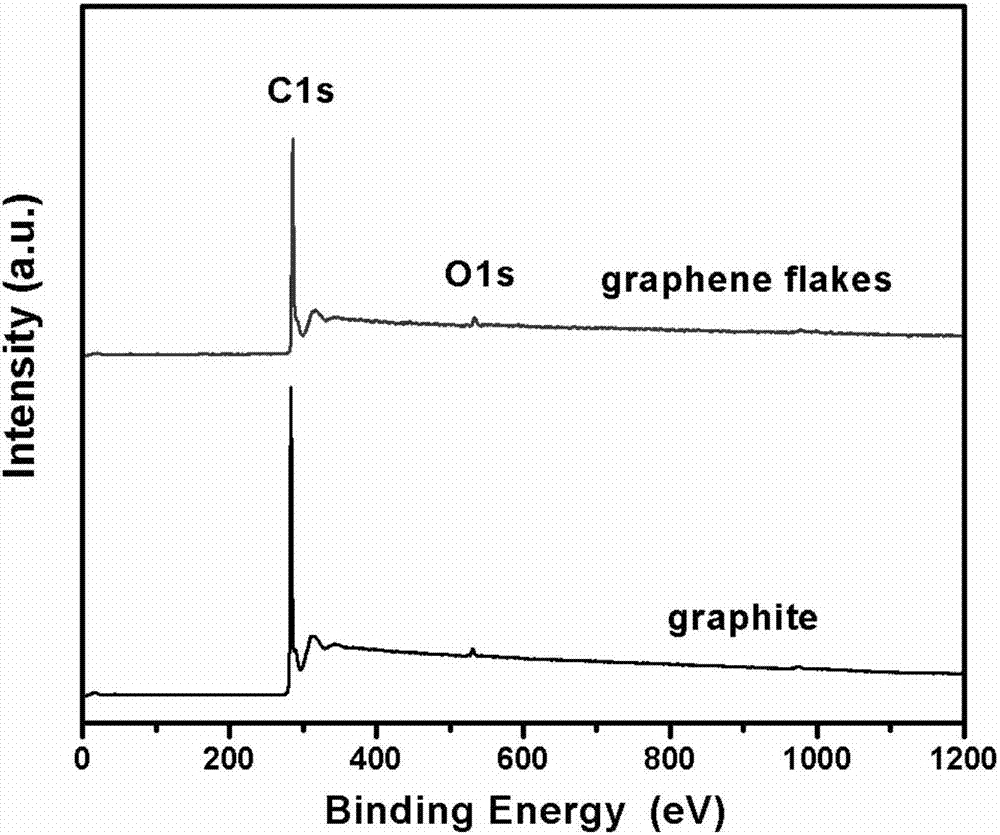

[0034] figure 1 It is the surface topography figure of t...

Embodiment 2

[0036] 1) In the Erlenmeyer flask, add 0.1g of graphite, 0.4g of ammonium persulfate and 26ml (about 50g) of chlorosulfonic acid in sequence, stir magnetically for 1min and mix well;

[0037] 2) Slowly add distilled water dropwise to the system in step 1), add 5ml of distilled water dropwise in total, and carry out the reaction. After the reaction is completed, a mixed solution system is obtained;

[0038] 3) Insert the 2000W ultrasonic probe into the liquid surface of the mixed solution system obtained in step 2), ultrasonically treat for 5min, wash with distilled water to neutrality, centrifuge at 3000rpm for 10min, remove the unreacted graphite in the lower layer, and collect the wet graphene in the upper layer;

[0039] 4) The wet graphene obtained in step 3) is freeze-dried for 5h to obtain graphene powder.

Embodiment 3

[0041] 1) In the Erlenmeyer flask, add 0.1g of graphite, 3g of potassium bicarbonate and 10ml (about 20g) of chlorosulfonic acid in sequence, stir magnetically for 1min and mix well;

[0042] 2) Slowly add 1ml of distilled water to the system in step 1), stir and react for 5 minutes, and obtain a mixed solution system after the reaction is completed;

[0043] 3) Insert the 50W ultrasonic probe into the liquid surface of the mixed solution system obtained in step 2), ultrasonically treat for 2h, wash with distilled water to neutrality, centrifuge at 1000rpm for 30min, remove the unreacted graphite in the lower layer, and collect the wet graphene in the upper layer;

[0044] 4) The wet graphene obtained in step 3) is freeze-dried for 10 h to obtain graphene powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com