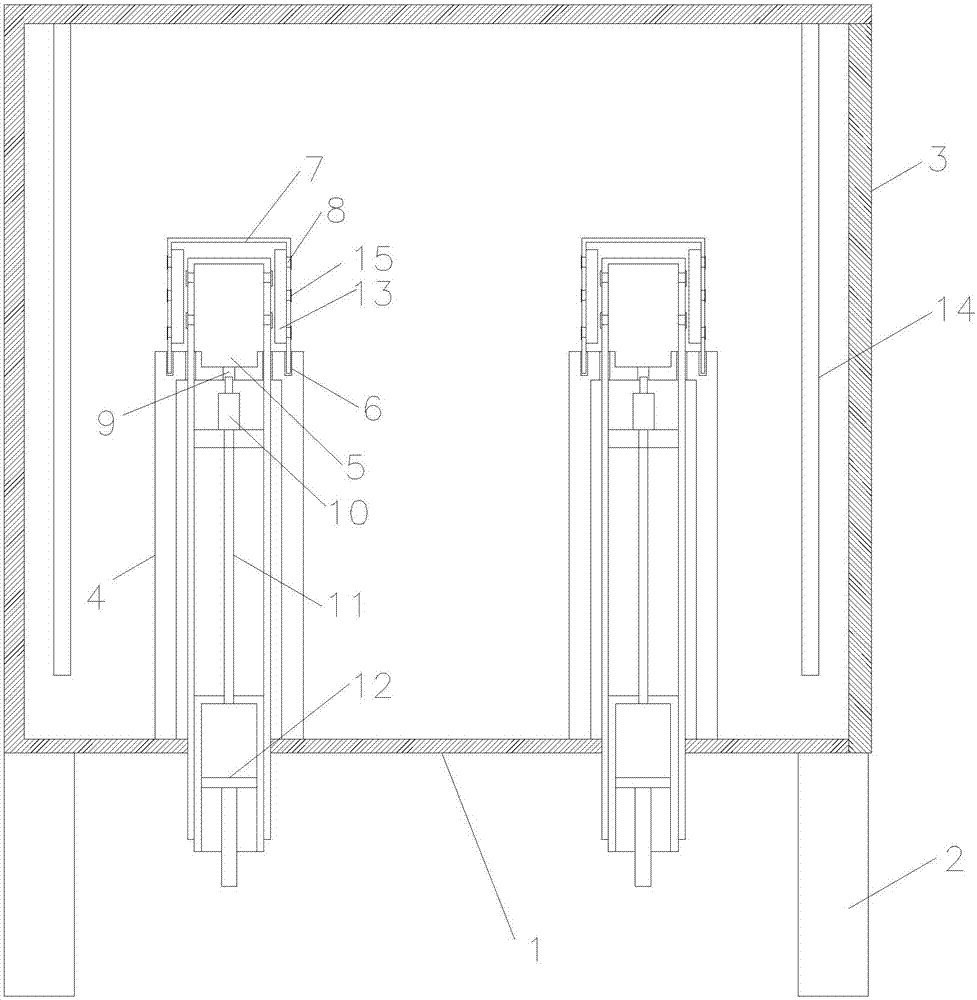

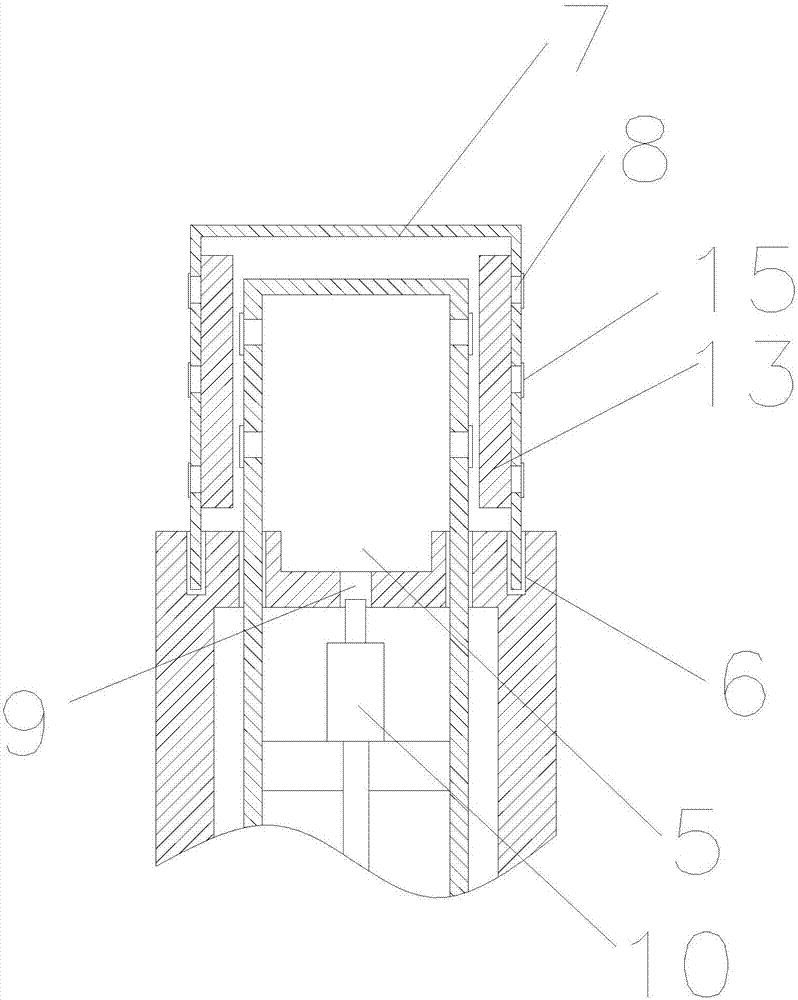

Porcelain sintering defoamer embedded in furnace

A technology of defoamer and silicone defoamer, which is applied in the field of ceramics and can solve problems such as poor plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

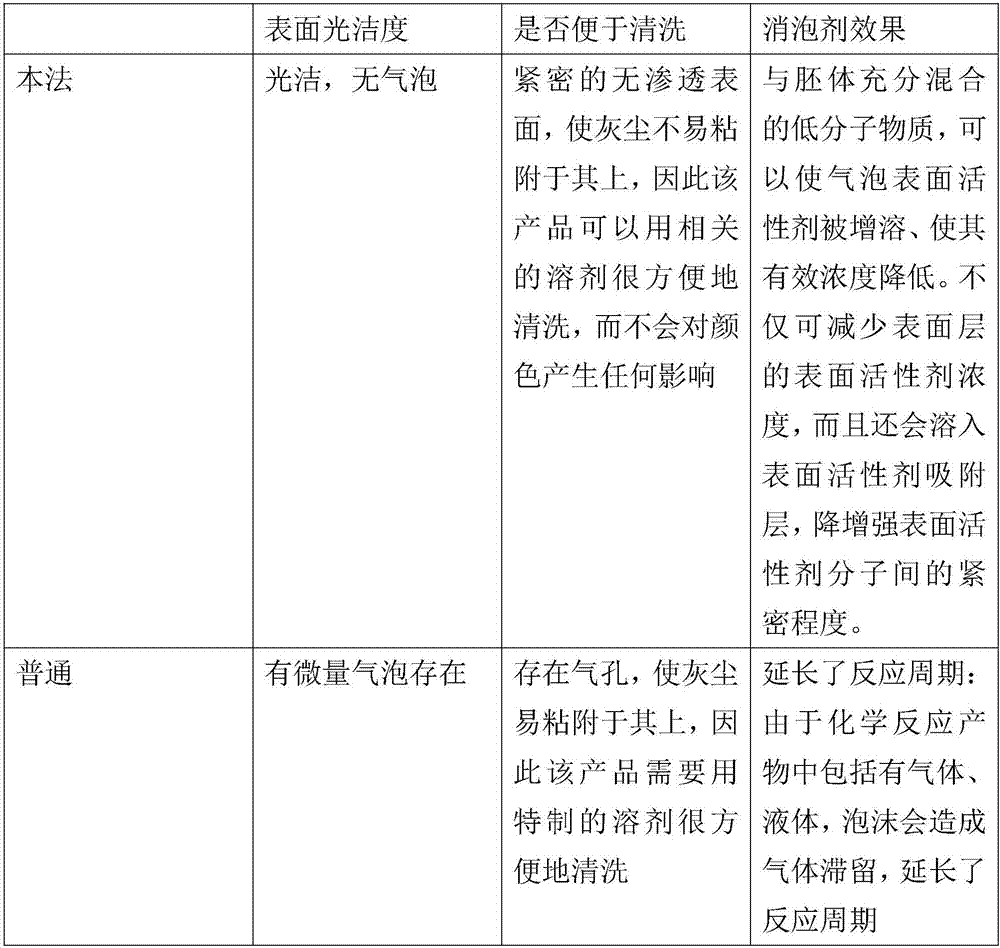

Examples

specific Embodiment 1

[0029] Specific embodiment 1: a kind of porcelain sintering defoamer built in kiln, including 10 parts of metal corrosion inhibitor, 100 parts of deionized water, 1 part of diethylene glycol, 2 parts of dispersant, polyethylene glycol 10 parts 40 parts of tap water, 10 parts of sweet potato stems and leaves, 10 parts of deionized water, 20 parts of forage, 10 parts of animal offal, 6 parts of modified silicone defoamer emulsion, 1 part of block polyether, 2 parts of quaternary ammonium salt , 1 part of hydrophobic silica, 3 parts of fluorine-containing polysiloxane, and 1 part of propylene oxide.

[0030] The preparation method of the antifoaming agent comprises the following steps: in a water tank filled with tap water, an aeration pump is used to increase oxygen in the water tank, and then adding sweet potato stems and leaves to the water tank every 24 hours, heating and transferring it to a tank filled with deionized water. In a water fermenter, at a temperature of 30-35°C,...

specific Embodiment 2

[0049] Specific embodiment 2: a kind of antifoaming agent for porcelain sintering built in the kiln, including 50 parts of metal corrosion inhibitors, 150 parts of deionized water, 5 parts of diethylene glycol, 5 parts of dispersants, polyethylene glycol 20 parts 50 parts of tap water, 15 parts of sweet potato stems and leaves, 50 parts of deionized water, 25 parts of forage, 13 parts of animal offal, 9 parts of modified silicone defoamer emulsion, 3 parts of block polyether, 10 parts of quaternary ammonium salt , 5 parts of hydrophobic silica, 5 parts of fluorine-containing polysiloxane, and 2 parts of propylene oxide.

[0050] The preparation method of the antifoaming agent comprises the following steps: in a water tank filled with tap water, an aeration pump is used to increase oxygen in the water tank, and then adding sweet potato stems and leaves to the water tank every 24 hours, heating and transferring it to a tank filled with deionized water. In a water fermenter, at a...

specific Embodiment 3

[0070] Specific embodiment 3: a kind of antifoaming agent for porcelain sintering built in the kiln, including 30 parts of metal corrosion inhibitors, 120 parts of deionized water, 3 parts of diethylene glycol, 3 parts of dispersants, polyethylene glycol 15 parts 45 parts of tap water, 13 parts of sweet potato stems and leaves, 30 parts of deionized water, 22 parts of fodder, 11 parts of animal offal, 7 parts of modified silicone defoamer emulsion, 2 parts of block polyether, 5 parts of quaternary ammonium salt , 3 parts of hydrophobic silica, 4 parts of fluorine-containing polysiloxane, and 2 parts of propylene oxide.

[0071] The preparation method of the antifoaming agent comprises the following steps: in a water tank filled with tap water, an aeration pump is used to increase oxygen in the water tank, and then adding sweet potato stems and leaves to the water tank every 24 hours, heating and transferring it to a tank filled with deionized water. In a water fermenter, at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com