High-strength waterproof emulsion, and preparation method thereof

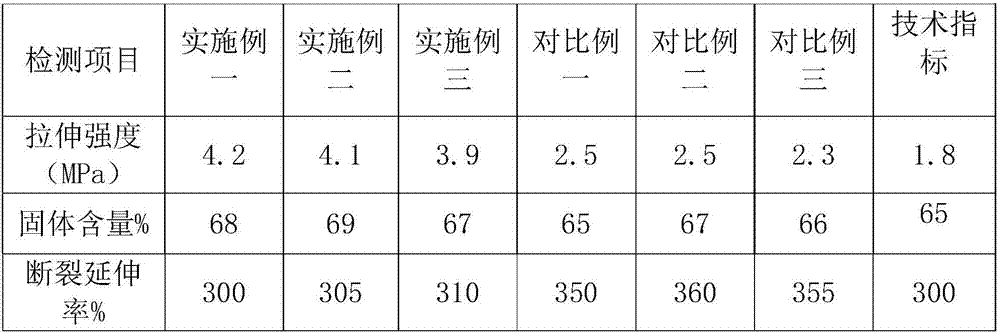

A waterproof emulsion, high-strength technology, applied in the direction of coating, can solve the problems of low tensile strength, difficult to guarantee quality, aging, etc., and achieve the effect of increasing tensile strength, increasing molecular weight, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

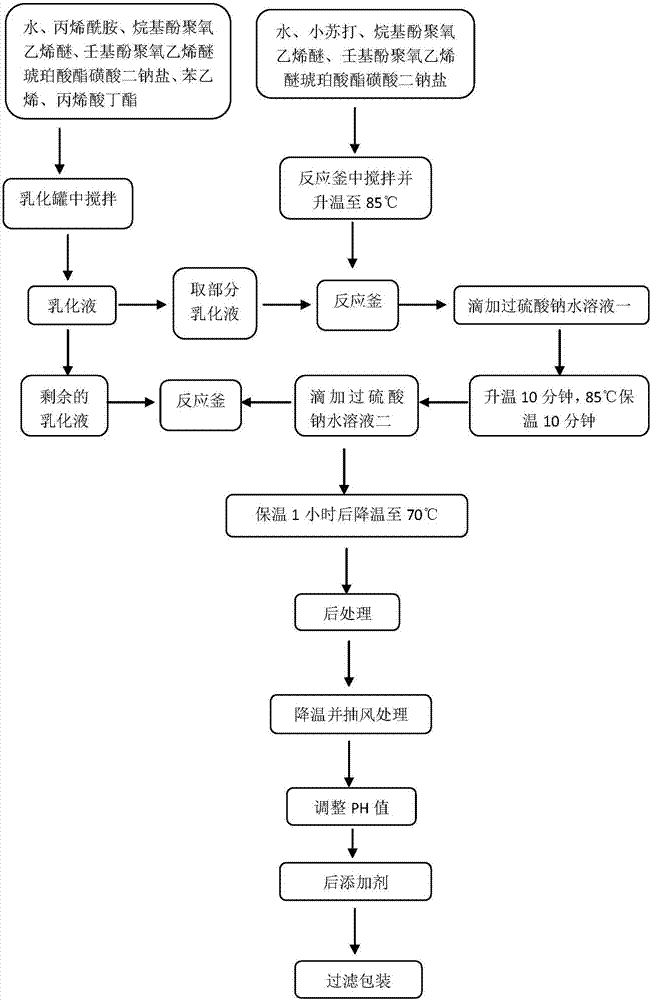

Method used

Image

Examples

Embodiment 1

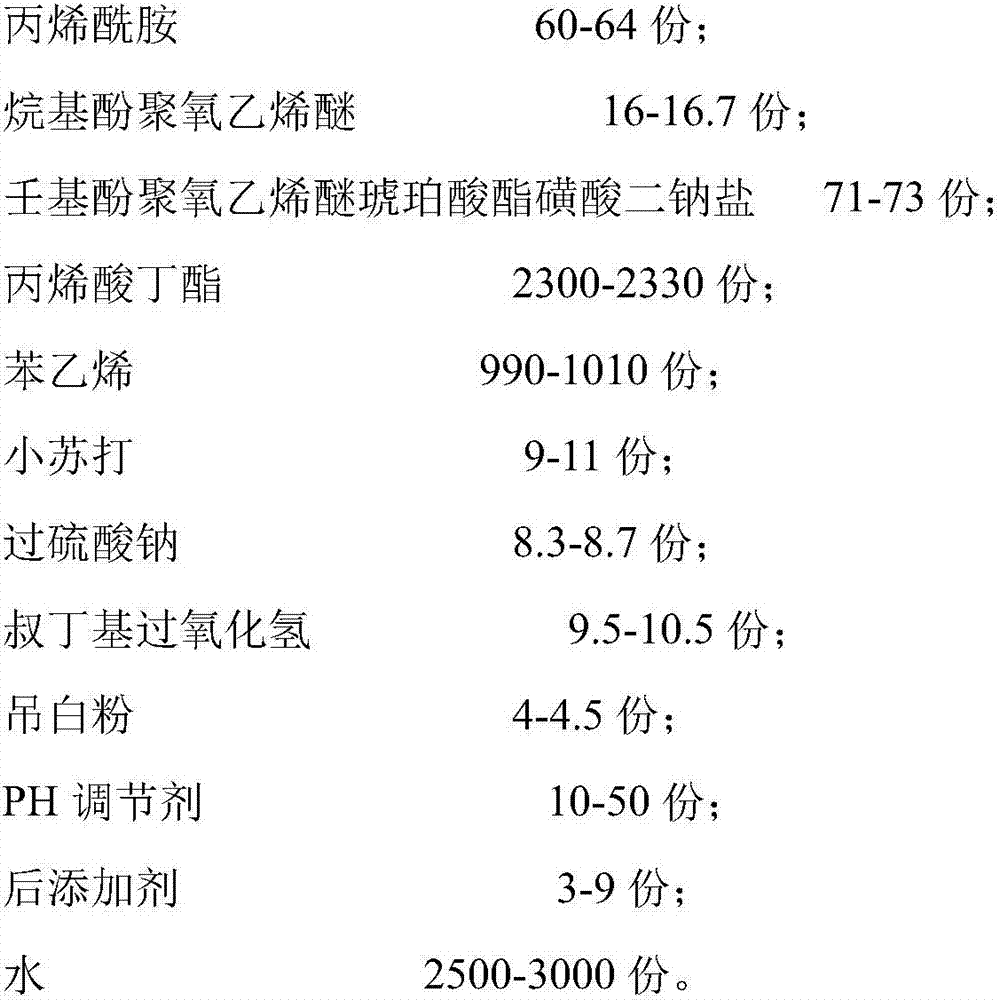

[0039] (1) Add 899kg of water, 62kg of acrylamide, 9.84kg of alkylphenol polyoxyethylene ether, 62.3kg of nonylphenol polyoxyethylene ether succinate sulfosuccinate disodium salt, 2317kg of butyl acrylate, and 1000kg of styrene in order Stir in the emulsification tank for 30 minutes to form a stable emulsion;

[0040] (2) Add 930kg of water, 10kg of baking soda, 6.6kg of alkylphenol polyoxyethylene ether, and 9.5kg of nonylphenol polyoxyethylene ether succinic acid disodium salt into the reaction kettle, stir and heat up to 85°C ;

[0041] (3) 210kg of the emulsion obtained in step (1) is added to the reactor;

[0042] (4) Add sodium persulfate aqueous solution one in reaction kettle within 10 minutes after step (3) ends, sodium persulfate aqueous solution one comprises 20kg water and 1kg sodium persulfate;

[0043] (5) After step (4) is completed, the temperature of the reactor is raised for 10 minutes, and then the temperature is controlled to 85° C. and kept for 10 minute...

Embodiment 2

[0052] (1) Add 920kg of water, 64kg of acrylamide, 10kg of alkylphenol polyoxyethylene ether, 63kg of nonylphenol polyoxyethylene ether succinate sulfosuccinate disodium salt, 2330kg of butyl acrylate, and 1010kg of styrene into the emulsification tank in order Stir in medium for 30 minutes to form a stable emulsion;

[0053](2) Add 930kg of water, 11kg of baking soda, 6.7kg of alkylphenol polyoxyethylene ether, and 10kg of nonylphenol polyoxyethylene ether succinate disodium sulfonate into the reactor, stir and heat up to 85°C;

[0054] (3) 200kg of the emulsion obtained in step (1) is added to the reactor;

[0055] (4) Add sodium persulfate aqueous solution one to the reactor within 10 minutes after step (3) ends, and sodium persulfate aqueous solution one includes 20kg water and 0.9kg sodium persulfate;

[0056] (5) After step (4) is completed, the temperature of the reactor is raised for 10 minutes, and then the temperature is controlled to 85° C. and kept for 10 minutes;...

Embodiment 3

[0065] (1) Add 890kg of water, 60kg of acrylamide, 9.5kg of alkylphenol polyoxyethylene ether, 62kg of nonylphenol polyoxyethylene ether succinate sulfosuccinate disodium salt, 2300kg of butyl acrylate, and 990kg of styrene into emulsification in order Stir in the tank for 30 minutes to form a stable emulsion;

[0066] (2) Add 930kg of water, 9kg of baking soda, 6.5kg of alkylphenol polyoxyethylene ether, and 9kg of nonylphenol polyoxyethylene ether succinate sulfosuccinate disodium salt into the reactor, stir and heat up to 85°C;

[0067] (3) 220kg of the emulsion obtained in the step (1) is added to the reactor;

[0068] (4) Add sodium persulfate aqueous solution 1 to the reactor within 10 minutes after step (3) ends, and sodium persulfate aqueous solution 1 includes 20kg water and 1.1kg sodium persulfate;

[0069] (5) After step (4) is completed, the temperature of the reactor is raised for 10 minutes, and then the temperature is controlled to 85° C. and kept for 10 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com