Aluminum and aluminum alloy efficient environmentally-friendly polishing solution and preparation method thereof

An aluminum alloy and polishing liquid technology, which is applied in the field of chemical treatment of metal material surfaces, can solve the problems of insufficient environmental protection awareness, insufficient polishing brightness, and graying of alloy surfaces in production enterprises, and is suitable for mass production, simple preparation process, chemical Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

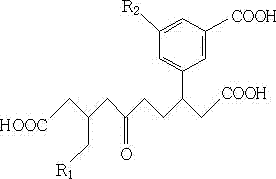

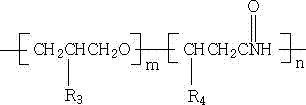

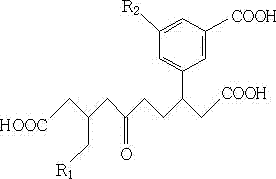

[0023] A high-efficiency and environmentally-friendly polishing solution for aluminum and aluminum alloys and a preparation method thereof, characterized in that the high-efficiency and environment-friendly polishing solution comprises the following components in parts by weight: 10 parts of sodium cocoyl isethionate, 1-phenyl- 3 parts of 5-mercaptotetrazole, 3 parts of sodium 3-mercapto-1-propanesulfonate, 0.1 part of copper sulfate, 0.3 part of sodium tungstate dihydrate, 1 part of corrosion inhibitor, 0.2 part of surfactant, 25 parts of sulfuric acid , 57.4 parts of deionized water. Among them, the corrosion inhibitor, in the molecular formula, R1 is hydroxyethyl, and R2 is methyl. Among them, the surfactant, in the molecular formula, R3 is isopropyl, R4 is p-methylphenyl, m=20, n=30.

[0024] A high-efficiency and environment-friendly polishing liquid for aluminum and aluminum alloys and a preparation method thereof, comprising the following steps:

[0025] (1) Sodium co...

Embodiment 2

[0031] A high-efficiency and environmentally-friendly polishing liquid for aluminum and aluminum alloys and a preparation method thereof. The high-efficiency and environmentally-friendly polishing liquid includes the following components in parts by weight: 20 parts of sodium cocoyl isethionate, 3-mercapto-1-propanesulfonic acid 5 parts of sodium, 0.3 parts of copper sulfate, 0.3 parts of sodium tungstate dihydrate, 1 part of corrosion inhibitor, 0.5 parts of surfactant, 35 parts of sulfuric acid, and 37.9 parts of deionized water. Among them, the corrosion inhibitor, in the molecular formula, R1 is hydroxyethyl, and R2 is methyl. Among them, the surfactant, in the molecular formula, R3 is isopropyl, R4 is p-methylphenyl, m=20, n=30.

[0032] A high-efficiency and environment-friendly polishing solution for aluminum and aluminum alloys and a preparation method thereof, is characterized in that it comprises the following steps:

[0033] (1) Sodium cocoyl isethionate and sodium...

Embodiment 3

[0039] A high-efficiency and environmentally-friendly polishing liquid for aluminum and aluminum alloys and a preparation method thereof, the high-efficiency and environmentally-friendly polishing liquid includes the following components in parts by weight: 15 parts of 1-phenyl-5-mercaptotetrazolium, 3-mercapto-1-propane 8 parts of sodium sulfonate, 0.6 parts of copper sulfate, 0.6 parts of sodium tungstate dihydrate, 2 parts of corrosion inhibitor, 0.2 parts of surfactant, 40 parts of sulfuric acid, 33.6 parts of deionized water. Among them, the corrosion inhibitor, in the molecular formula, R1 is hydroxyethyl, and R2 is methyl. Wherein the surfactant, in the molecular formula, R3 is a hydrogen atom, R4 is a hydrogen atom, m=25, n=25.

[0040] A high-efficiency and environment-friendly polishing solution for aluminum and aluminum alloys and a preparation method thereof, is characterized in that it comprises the following steps:

[0041] (1) Dissolve 1-phenyl-5-mercaptotetraz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com