A composite electrically conductive fiber and a preparing method thereof

A composite conductive and fiber technology, applied in fiber processing, fiber types, textiles and papermaking, etc., can solve the problems of low preparation efficiency and inability to prepare high strength composite conductive fibers with high conductivity and high cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

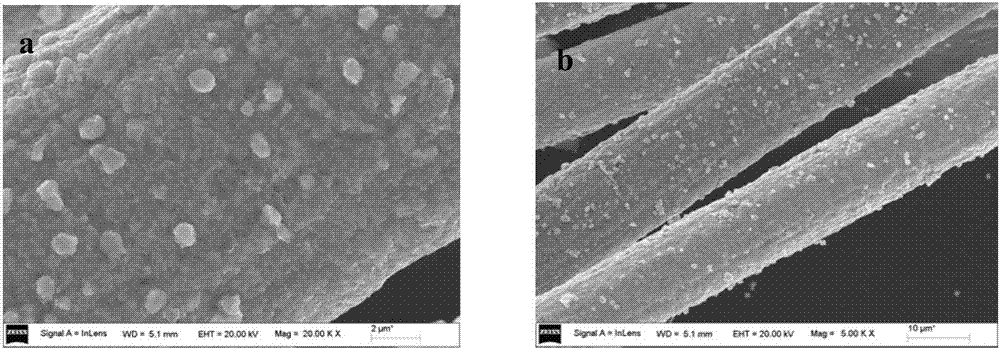

Embodiment 1

[0072] This example is used to illustrate the composite conductive fiber provided by the present invention and its preparation method.

[0073] a. Degreasing: Under ultrasonic conditions with a power of 20W / L, wash the aramid fiber in ethanol for 20 minutes, rinse it with deionized water for 5 times after cleaning, and dry it in vacuum for later use;

[0074] b. Polymer coating: prepare bisphenol A diether dianhydride (BPADA) and 4'4-diaminodiphenyl ether (ODA) monomer solution, the concentration is 50g / L, the aramid fiber after degreasing Placed in the monomer solution and reacted at 10°C for 13 hours to obtain polyamic acid-coated aramid fibers;

[0075] c. ultrasonically clean the aramid fibers obtained in step b with a mixed solution of deionized water and N-methylpyrrolidone (wherein the content of N-methylpyrrolidone is 5% by weight) at 45°C for 3 times, each cleaning The time is 20 minutes, the ultrasonic power is 20W / L, the amount of the mixed solution is only require...

Embodiment 2

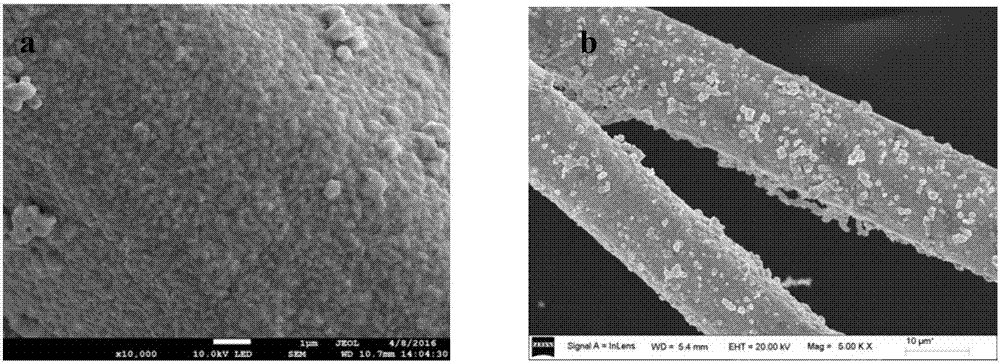

[0082] This example is used to illustrate the composite conductive fiber provided by the present invention and its preparation method.

[0083] a. Degreasing: Under ultrasonic conditions with a power of 30W / L, place the aramid fiber in dimethyl sulfoxide for 40 minutes, rinse it with deionized water for 5 times, and dry it in vacuum for later use;

[0084] b. Polymer coating: prepare vinyl chloride-vinyl acetate monomer solution, the concentration of vinyl chloride is 300mL / L, and the concentration of vinyl acetate is 80g / L, and the aramid fibers after degreasing are placed in the monomer solution at 50 Reaction at ℃ for 13 hours to obtain aramid fiber coated with vinyl acetate resin;

[0085] c. ultrasonically clean the aramid fibers obtained in step b with a mixed solution of deionized water and dimethyl sulfoxide (wherein the content of dimethyl sulfoxide is 10% by weight) at 50°C for 5 times, each cleaning The time is 20 minutes, the ultrasonic power is 30W / L, the amount ...

Embodiment 3

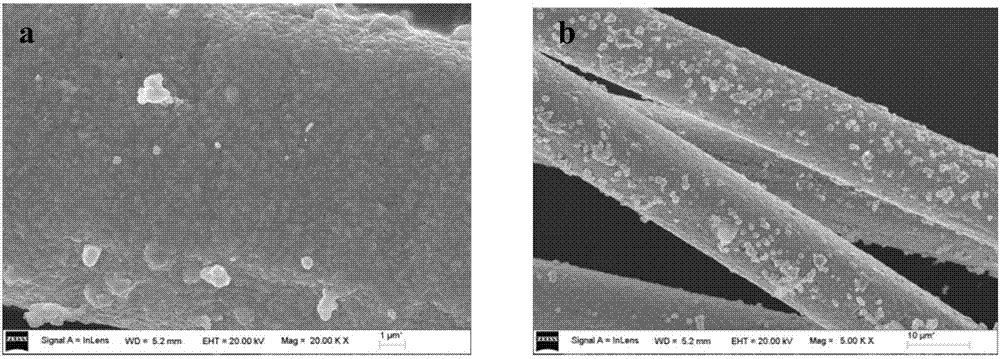

[0092] This example is used to illustrate the composite conductive fiber provided by the present invention and its preparation method.

[0093] a. Degreasing: Under ultrasonic conditions with a power of 40W / L, place the aramid fiber in carbon tetrachloride for 40 minutes, rinse it with deionized water for 3 times, and dry it in vacuum for later use;

[0094] b. Polymer coating: Prepare an aqueous solution of dopamine monomer with a concentration of 4g / L, place the aramid fibers after degreasing in the monomer solution and react at 30°C for 15 hours to obtain polydopamine-coated aramid fibers ;

[0095] c. ultrasonically clean the aramid fibers obtained in step b with a mixed solution of deionized water and N-methylpyrrolidone (wherein the content of N-methylpyrrolidone is 30% by weight) at 80°C for 3 times, each cleaning The time is 20 minutes, the ultrasonic power is 30W / L, the amount of the mixed solution is only required to make the aramid fibers completely immersed in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com