Manufacturing method of metal housing for packaging electronic assembly

A metal shell, packaging electronics technology, applied in the manufacturing of electrical components, electric solid state devices, semiconductor/solid state devices, etc., can solve the problems of inability to meet the heat dissipation requirements of internal circuits, high manufacturing costs of metal shells, and insufficient matching, and achieve savings Production cost, light weight, and the effect of meeting heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The manufacturing method of the metal casing for encapsulating electronic components will be described in detail below through specific embodiments and accompanying drawings.

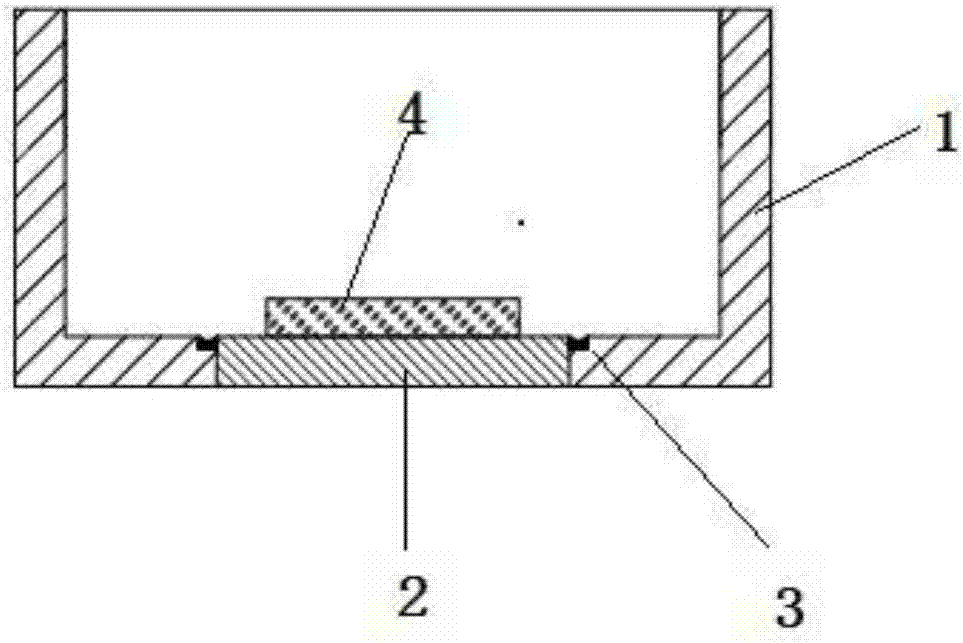

[0019] The method for manufacturing a metal case for encapsulating electronic components provided by the present invention, wherein the metal case includes a metal case body and a diamond copper heat sink plate embedded on the bottom plate of the metal case body, and the electronic components are mounted on the diamond copper heat sink plate, including the following steps,

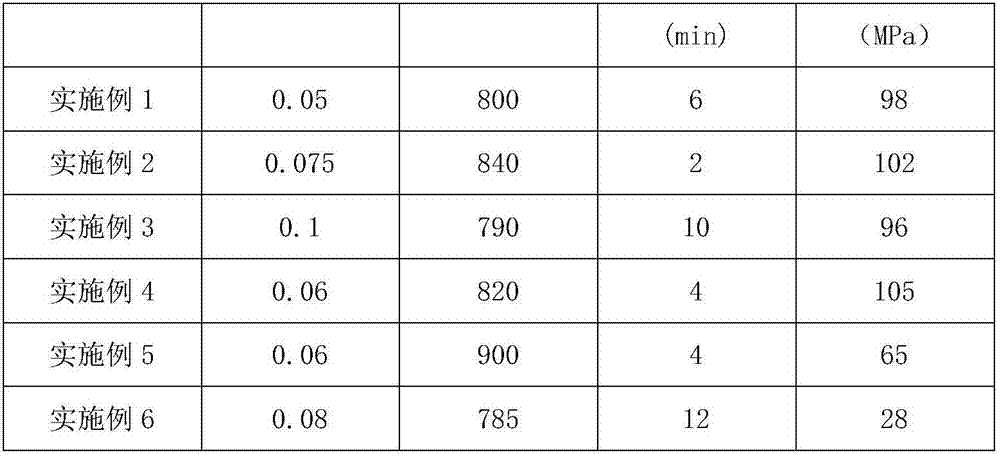

[0020] 1) Process the metal shell body and the diamond copper heat sink plate, so that the bottom of the metal shell body forms an empty groove for inserting the diamond copper heat sink plate, and make the gap between the empty groove and the diamond copper heat sink plate range from 0.05 to 0.10 mm;

[0021] 2) nickel-plate the surface of the metal shell body and the diamond copper heat sink plate processed in step 1), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com