Austenitic stainless steel part machining method

A technology of austenitic stainless steel and processing methods, which is applied in the field of stainless steel parts processing, can solve the problems of difficult machining of austenitic stainless steel parts, achieve the effects of reducing tool wear, reducing production costs, and improving machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

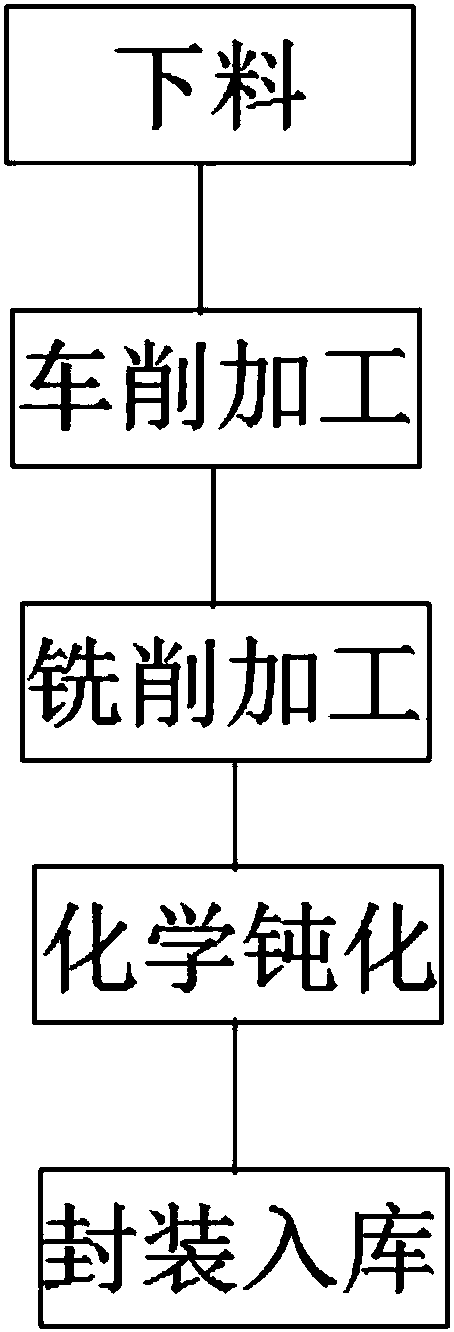

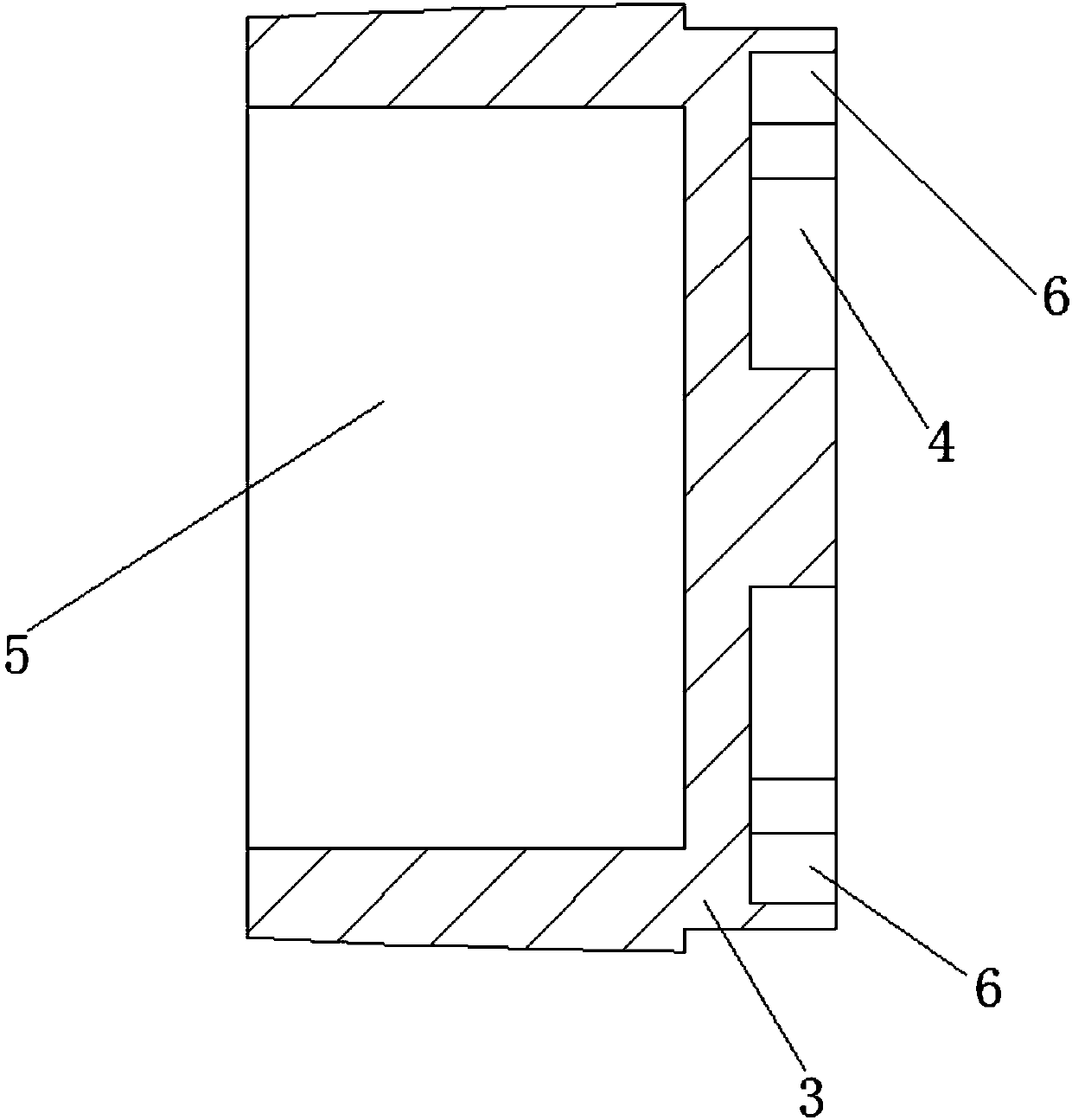

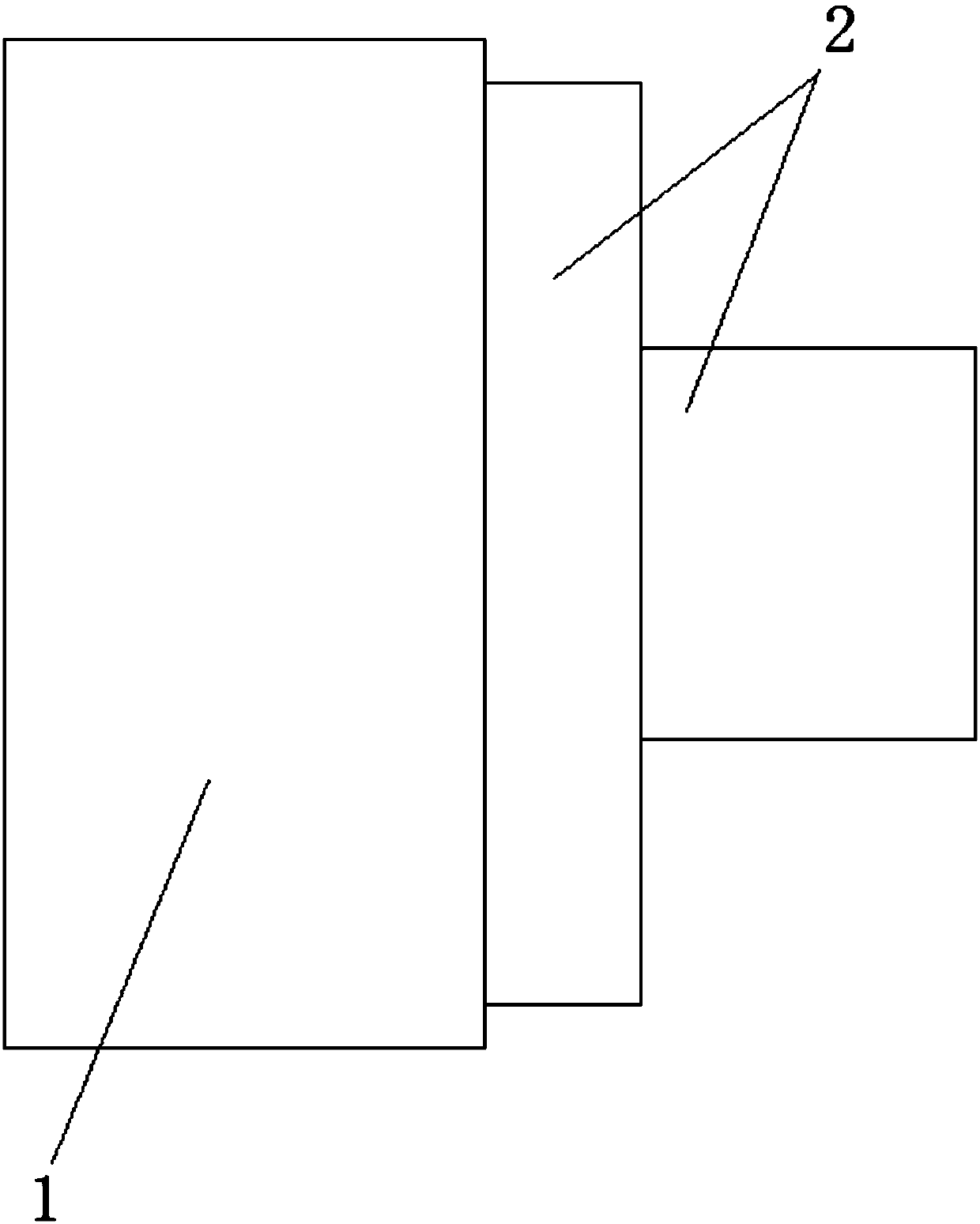

[0041] Such as figure 1 As shown, a processing method for austenitic stainless steel parts, selects 06Cr18Ni11Ti austenitic stainless steel material, and processes a part whose shape is a body of revolution and whose shape is a parabolic curved surface 3. Cavities are provided at both ends of the parabolic curved surface 3 .

[0042] Include the following steps:

[0043] ①Blanking: blanking stainless steel rod 06Cr18Ni11Ti, after blanking, remove flash and burrs;

[0044] ②Turning: Turning stainless steel rod 06Cr18Ni11Ti to make parts;

[0045] ③Milling processing: Milling the inscribed circle of the part, making the cavity, removing the processing burr after milling, positioning with the inscribed circle, milling another cavity, and removing the processing burr after milling;

[0046] ④Chemical passivation: Clean the parts an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com