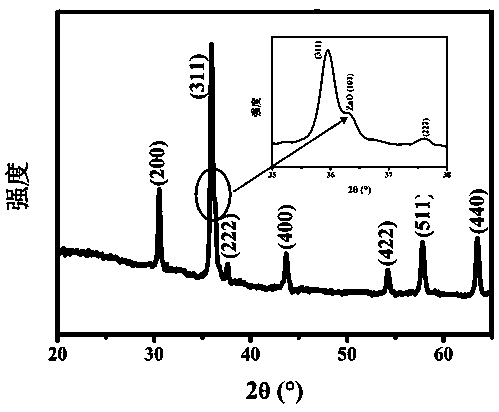

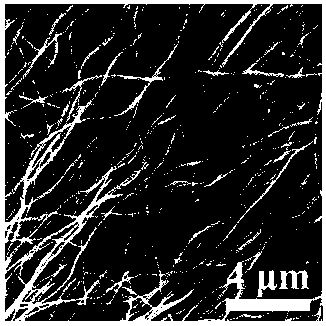

a beaded cumn 2 o 4 /zno composite fiber preparation method and resulting product

A composite fiber and bead chain technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the difficult control of the stability and dispersion of MOFs particles in the precursor spinning solution, and the factors affecting the electrospinning process There are many issues that need to be further explored to achieve the effects of easy control of the reaction process, novel technical routes, and special microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1.1 Zinc nitrate hexahydrate (Zn(NO) of 0.7419 g 3 ) 2 ∙6H 2 O) and 0.8188 g of 2-methylimidazole were separately dissolved in 50 mL of anhydrous methanol, and stirred to obtain a transparent solution; then the methanol solution of zinc nitrate and the methanol solution of 2-methylimidazole were mixed, and stirred evenly for 1 h. Stand still for 24 h, then centrifuge and wash with methanol for 3 times, place in an evaporating dish and dry naturally to obtain a Zif-8 product with a size of 45-53 nm;

[0035] 1.2 Dissolve 0.0118 g of DDAB and 0.0059 g of EDTA in a mixed solvent of 3.0 mL of ethanol and 1.0 mL of glycerol, stir to obtain a transparent solution, then add 0.0057 g of Zif-8 nanoparticles and stir to obtain a Zif-8 solution;

[0036] 1.3 0.1208 g of copper nitrate trihydrate (Cu(NO 3 ) 2 ∙3H 2 O), 0.2451 g of manganese acetate tetrahydrate (Mn(Ac) 2 ∙4H 2 O) and 0.7000 g of PVP were added to the mixed solvent of 1.0 mL of ethanol and 4.0 mL of DMF, and ...

Embodiment 2

[0040] 2.1 Add 0.7419 g of Zn(NO 3 ) 2 ∙6H 2 O and 0.7310 g of 2-methylimidazole were separately dissolved in 46 mL of anhydrous methanol, and stirred to obtain a transparent solution; then the methanol solution of zinc nitrate and the methanol solution of 2-methylimidazole were mixed, and stirred for 2 h after mixing evenly , standing for 24 h, then centrifuged and washed 3 times with anhydrous methanol, placed in an evaporating dish and dried naturally to obtain a Zif-8 product with a size of 36-42 nm;

[0041] 2.2 Dissolve 0.0019 g of DDAB and 0.0014 g of EDTA in a mixed solvent of 3.0 mL of ethanol and 1.0 mL of glycerol, stir to obtain a transparent solution, then add 0.0011 g of Zif-8 nanoparticles and stir to obtain a Zif-8 solution;

[0042] 2.3 Add 0.0793 g of Cu(NO 3 ) 2 ∙3H 2 O, 0.1609 g of Mn(Ac) 2 ∙4H 2 The PVP of 0 and 0.2922 g joins in the mixed solvent of the ethanol of 1.0 mL and the DMF of 4.0 mL, stirs to obtain a transparent solution; Then all the Zi...

Embodiment 3

[0045] 3.1 Add 0.7419 g of Zn(NO 3 )2 ∙6H 2 O and 0.8908 g of 2-methylimidazole were separately dissolved in 47 mL of anhydrous methanol, and stirred to obtain a transparent solution; then the methanol solution of zinc nitrate and the methanol solution of 2-methylimidazole were mixed, and stirred for 2 h after mixing evenly , standing for 24 h, then centrifuged and washed 3 times with anhydrous methanol, placed in an evaporating dish and dried naturally to obtain a Zif-8 product with a size of 33-38 nm;

[0046] 3.2 Dissolve 0.0323 g of DDAB and 0.0106 g of EDTA in a mixed solvent of 3.0 mL of ethanol and 1.0 mL of glycerol, stir to obtain a transparent solution, then add 0.0133 g of Zif-8 nanoparticles and stir to obtain a Zif-8 solution;

[0047] 3.3 Add 0.1769 g of Cu(NO 3 ) 2 ∙3H 2 O, 0.3590 g of Mn(Ac) 2 ∙4H 2 The PVP of 0 and 1.1106 g joins in the mixed solvent of the ethanol of 1.0 mL and the DMF of 4.0 mL, stirs to obtain a transparent solution; Then the Zif-8 so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com