A preparation method of carbon tube and carbon nanofiber composite airgel based on cobalt sulfide growth

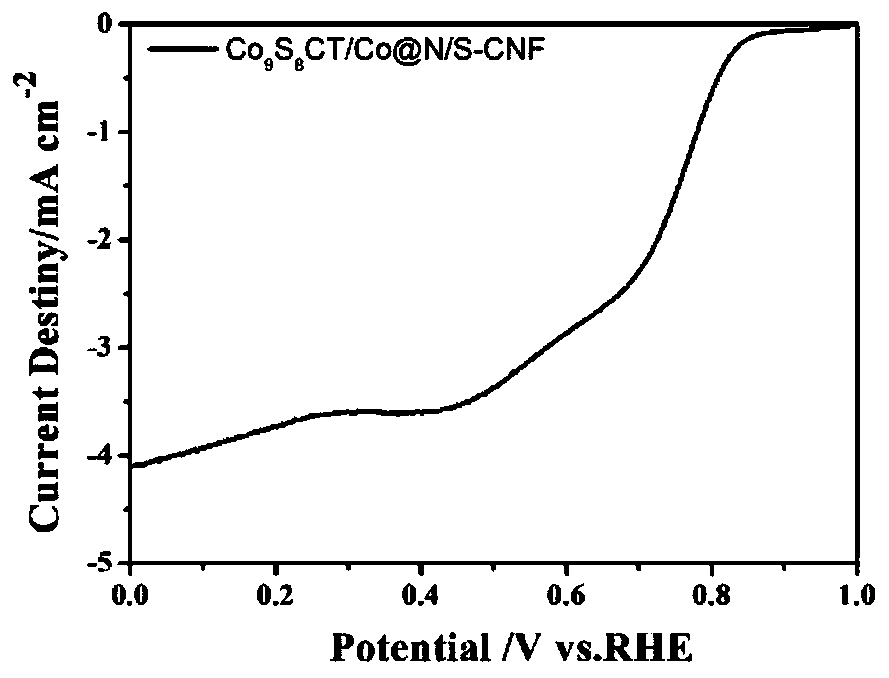

A composite airgel and carbon nanofiber technology, applied in the field of composite materials, can solve the problems of material specific surface area limitation, achieve the effect of increasing specific surface area, good stability, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

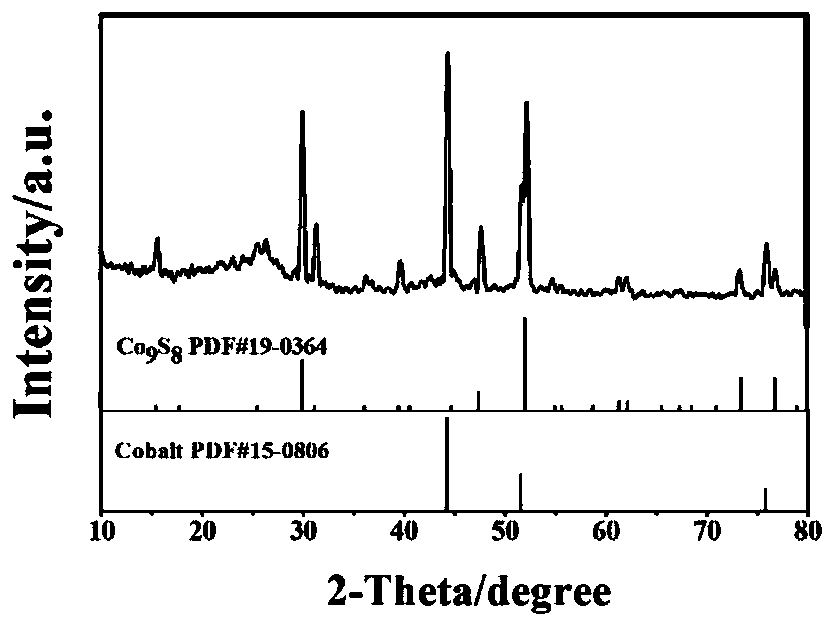

[0022] 1) Cut the bacterial cellulose hydrogel into rectangles (1*3*2cm 3 ), soaked in deionized water for 24 hours, freeze-dried for 72 hours to obtain airgel, impregnated the airgel in a solution containing 0.1M cobalt chloride, 0.2M thiourea, and 1.0M urea at room temperature for 72 hours, and then The resulting composite hydrogel was frozen by immersion in liquid nitrogen, and then vacuum freeze-dried.

[0023] 2) Under a nitrogen atmosphere, heat the product obtained in step 1 to 200°C at a heating rate of 2°C / min, then to 220°C at a heating rate of 1°C / min, keep it warm for 1 hour, and then heat it at a rate of 1°C / min The heating rate was raised to 350°C, kept for 1 hour, and finally the temperature was raised to 900°C within 180 minutes. After natural cooling, the carbon tube and carbon nanofiber composite airgel based on cobalt sulfide growth was obtained.

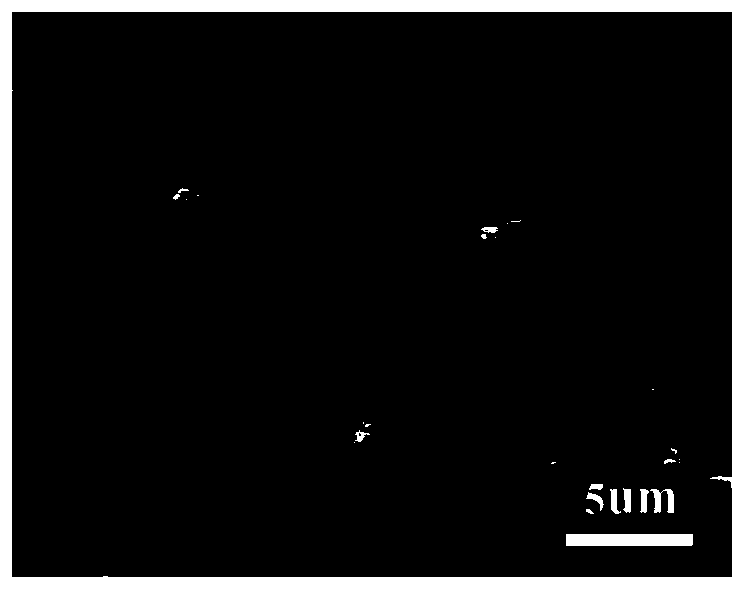

[0024] 3) SEM testing was carried out using a FEI Quanta FEG 250 scanning electron microscope from Philips, t...

Embodiment 2

[0028] 1) Cut the bacterial cellulose hydrogel into rectangles (1*3*2cm 3 ), soaked in deionized water for 24 hours, freeze-dried for 72 hours to obtain airgel, impregnated the airgel in a solution containing 0.1M cobalt chloride, 0.2M thiourea, and 1.0M urea at room temperature for 72 hours, and then The resulting composite hydrogel was frozen by immersion in liquid nitrogen, and then vacuum freeze-dried.

[0029] 2) Under a nitrogen atmosphere, heat the product obtained in step 1 to 200°C at a heating rate of 2°C / min, then to 220°C at a heating rate of 1°C / min, keep it warm for 1 hour, and then heat it at a rate of 1°C / min The heating rate was raised to 350°C, kept for 1 hour, and finally the temperature was raised to 900°C within 180 minutes. After natural cooling, the carbon tube and carbon nanofiber composite airgel based on cobalt sulfide growth was obtained.

[0030] 3) SEM testing was carried out using a FEI Quanta FEG 250 scanning electron microscope from Philips, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com