Preparation method of ag/zno-carbon sphere ternary core-shell heterojunction photocatalyst with different microscopic morphology

A photocatalyst and heterojunction technology, which can be used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. problems, to achieve excellent visible light catalytic performance, simplify the synthesis process, and increase the specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

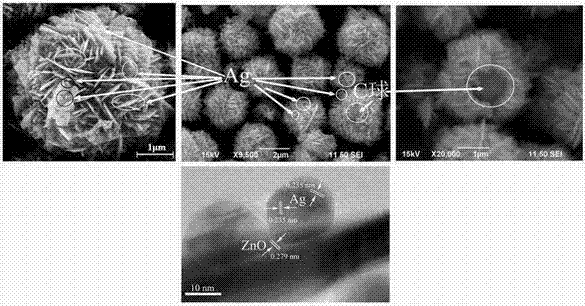

Embodiment 1

[0015] Put 0.2M glucose solution in a hydrothermal reaction kettle and conduct a hydrothermal reaction at 180°C for 12 hours to obtain carbon spheres with an average diameter of 0.2 μm; disperse 5 mg of the obtained carbon spheres into a mixed solution formed of zinc nitrate and sodium citrate, in which nitric acid The molar ratio of zinc to sodium citrate is 3:1, the mass ratio of carbon spheres to zinc nitrate is 0.005:3.71, and then the sodium hydroxide solution is added dropwise under stirring until the pH value of the mixed solution is 13.5 to form a suspension; Add 11 mL of silver nitrate solution with a molar concentration of 0.1 mol / L to the above suspension under stirring conditions, stir evenly, transfer to a hydrothermal reaction kettle and react at 90°C for 12 hours, then centrifuge the precipitate obtained after the hydrothermal reaction Separation, washing, and vacuum drying at 60°C to obtain flake-like Ag / ZnO-carbon sphere ternary core-shell heterojunction photoc...

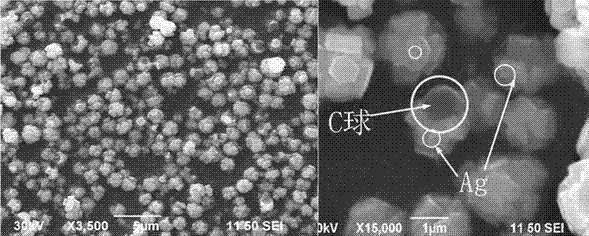

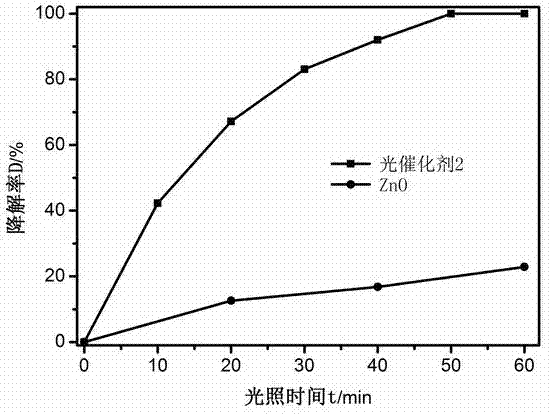

Embodiment 2

[0017] Put 0.5M glucose solution in a hydrothermal reaction kettle and conduct a hydrothermal reaction at 180°C for 8 hours to obtain carbon spheres with an average diameter of 1 μm; disperse 25 mg of the obtained carbon spheres into a mixed solution formed of zinc nitrate and sodium citrate, in which zinc nitrate The mol ratio with sodium citrate is 1.8:1, the mass ratio of carbon spheres and zinc nitrate is 0.025:3.71, then drip sodium hydroxide solution under stirring condition to the pH value of mixed solution to form a suspension at 12.5; Add 9 mL of silver nitrate solution with a molar concentration of 0.1 mol / L dropwise to the above suspension under stirring conditions, stir evenly, transfer to a hydrothermal reaction kettle and react at 100°C for 4 hours, then centrifuge the precipitate obtained after the hydrothermal reaction , washed, and then vacuum-dried at 60°C to obtain flake-like Ag / ZnO-carbon sphere ternary core-shell heterojunction photocatalyst 2.

Embodiment 3

[0019] Put 0.5M glucose solution in a hydrothermal reaction kettle and conduct a hydrothermal reaction at 180°C for 8 hours to obtain carbon spheres with an average diameter of 1 μm; disperse 50 mg of the obtained carbon spheres into a mixed solution formed of zinc nitrate and sodium citrate, in which zinc nitrate The mol ratio with sodium citrate is 1.25:1, the mass ratio of carbon spheres and zinc nitrate is 0.05:3.71, then drip sodium hydroxide solution under stirring condition to the pH value of mixed solution to form a suspension at 11.5; Add 2 mL of silver nitrate solution with a molar concentration of 0.1 mol / L dropwise to the above suspension under stirring conditions, stir evenly, transfer to a hydrothermal reaction kettle and react at 110°C for 10 hours, then centrifuge the precipitate obtained after the hydrothermal reaction , washed, and then vacuum-dried at 60°C to obtain stylized Ag / ZnO-carbon sphere ternary core-shell heterojunction photocatalyst 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com