Organic electroluminescence material and organic luminescent device

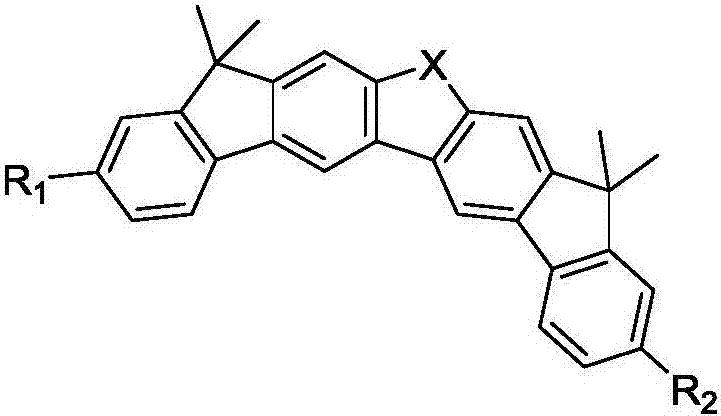

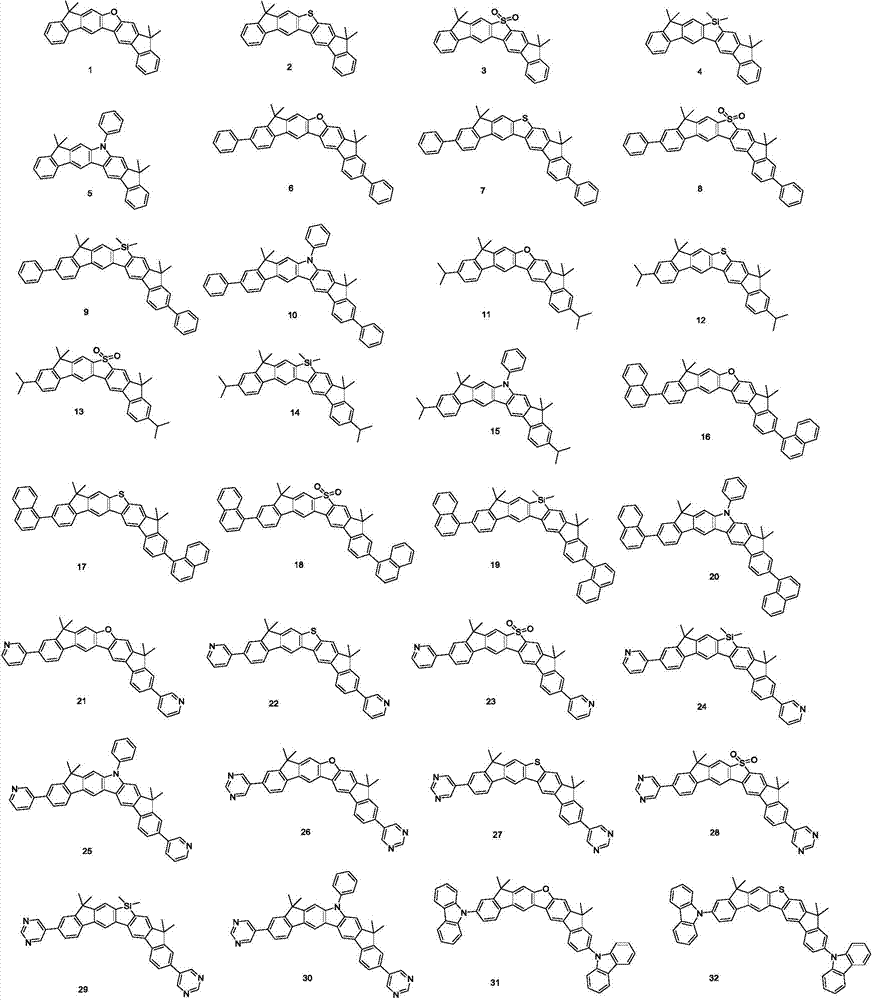

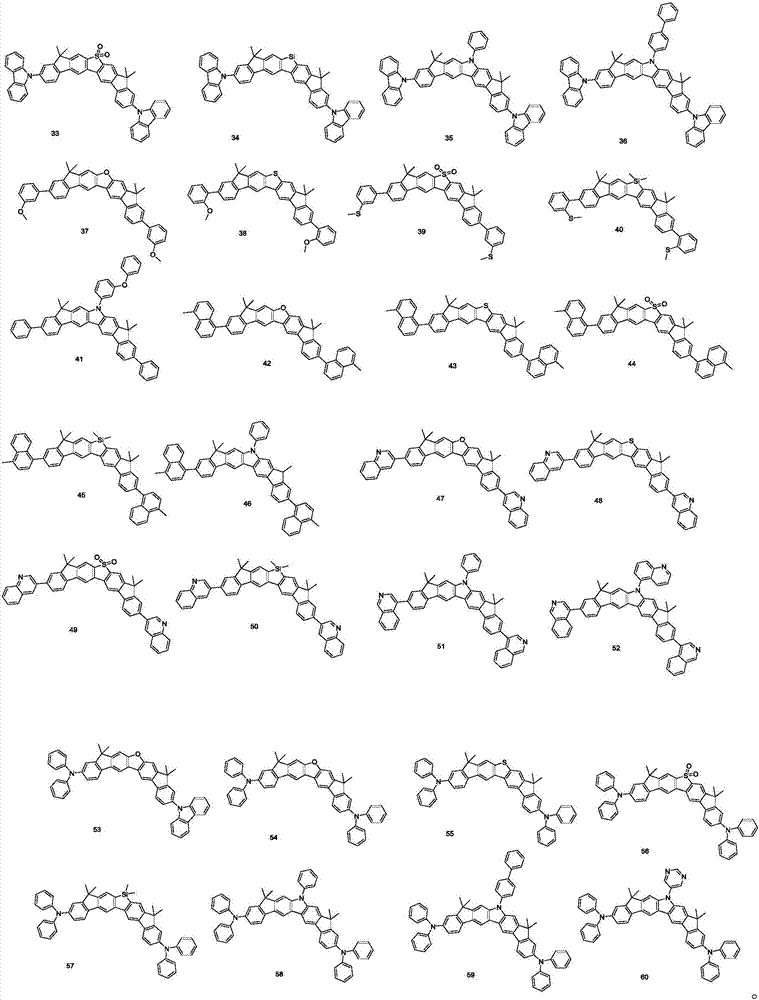

An electroluminescent material and organic technology, applied in the direction of luminescent materials, electrical solid devices, electrical components, etc., can solve the problems of high driving voltage, low luminous efficiency, poor luminous performance, etc., to increase equilibrium movement and improve glass transition Effect of high temperature, glass transition temperature and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: 1 synthesis of compound

[0041]

[0042] Step1. Take 1-0 100mmol, add 2 equivalents of o-carboxyphenylboronic acid, 300mmol sodium carbonate, 1mmol tetrakistriphenylphosphopalladium, toluene, ethanol, water mixed solvent, replace with argon three times, react at reflux temperature for 10h, crude The product was passed through a silica gel column to obtain 85 mmol of compound 1-1.

[0043] Step2. Under the protection of nitrogen, add 10 equivalents of methanesulfonic acid and 85mmol of intermediate 1-1 to the reactor, stir and react at room temperature for 5h, then add distilled water to terminate the reaction to obtain a precipitate, and prepare the intermediate through silica gel column chromatography / liquid phase 1-241 mmol.

[0044] Step3. Take raw material 1-2 41mmol, add solvent trifluoroacetic acid, triethylsilane 10 equivalents, and stir the mixture at room temperature overnight. After the reaction is completed, put the reaction solution into wat...

Embodiment 2

[0046] Embodiment 2: 2 synthesis of compound

[0047]

[0048] Step1. Take 100mmol of 2-0, add 2 equivalents of o-carboxyphenylboronic acid, 300mmol sodium carbonate, 1mmol tetrakistriphenylphosphopalladium, toluene, ethanol, water mixed solvent, replace with argon three times, react at reflux temperature for 10h, crude The product was passed through a silica gel column to obtain 85 mmol of compound 2-1.

[0049] Step2. Under the protection of nitrogen, add 10 equivalents of methanesulfonic acid and 85mmol of intermediate 2-1 to the reactor, stir and react at room temperature for 5h, and then add distilled water to terminate the reaction to obtain a precipitate, which is prepared by silica gel column chromatography / liquid phase to obtain the intermediate 2-241 mmol.

[0050] Step3. Take raw material 2-2 41mmol, add solvent trifluoroacetic acid, triethylsilane 10 equivalents, and stir the mixture at room temperature overnight. After the reaction is completed, put the reacti...

Embodiment 3

[0052] Embodiment 3: 3 synthesis of compound

[0053]

[0054] Step1. Take 100mmol of 2-0, add 2 equivalents of o-carboxyphenylboronic acid, 300mmol sodium carbonate, 1mmol tetrakistriphenylphosphopalladium, toluene, ethanol, water mixed solvent, replace with argon three times, react at reflux temperature for 10h, crude The product was passed through a silica gel column to obtain 85 mmol of compound 2-1.

[0055] Step2. Under the protection of nitrogen, add 10 equivalents of methanesulfonic acid and 85mmol of intermediate 2-1 to the reactor, stir and react at room temperature for 5h, and then add distilled water to terminate the reaction to obtain a precipitate, which is prepared by silica gel column chromatography / liquid phase to obtain the intermediate 2-241 mmol.

[0056] Step3. Take raw material 2-2 41mmol, add solvent trifluoroacetic acid, triethylsilane 10 equivalents, and stir the mixture at room temperature overnight. After the reaction is completed, put the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com