Oxaliplatin impurity c and its preparation method and application

A technology of oxaliplatin and impurities, which is applied in the field of chemical synthesis, can solve the problems of low yield and low purity, and achieve the effects of low preparation cost, simple preparation method and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

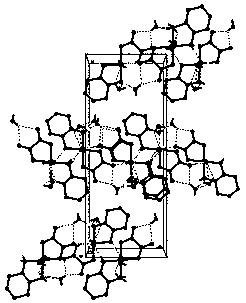

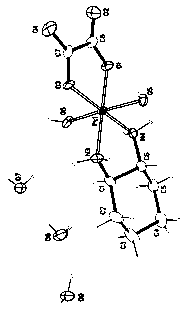

Image

Examples

Embodiment 1

[0043] (1) Oxidation Take 5.0g of oxaliplatin raw material, put it in a 3000mL measuring bottle, add 1000mL of water, and dissolve it by ultrasonic (power: 500W, frequency: 40kHz) for 10 minutes, and fill the bottle with excess oxygen at 30°C. Seal it, let it stand for 1 hour, and let it stand for 4 times with oxygen.

[0044] (2) Preparation of crude product Concentrate the above solution to 500mL under reduced pressure with a Buchi R210 rotary evaporator (temperature: 80°C, vacuum degree: 100mbar, rotation speed: 60 rpm), and evaporate to dryness on a water bath to obtain 5.52g of impurity C crude product .

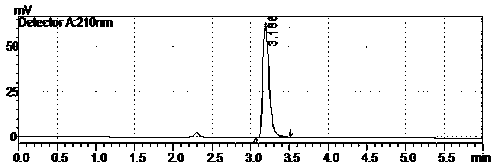

[0045] (3) Recrystallization Take the crude product of impurity C, add 1000mL of water, heat to 80°C in a water bath, dissolve it with ultrasound (power: 500W, frequency: 40kHz) for 30 minutes, filter, and use Buchi R210 rotary evaporator for the filtrate (temperature: 80°C, vacuum Degree: 100mbar, rotation speed: 60 rpm) concentrated under reduced pressure to 400mL, pla...

Embodiment 2

[0049] (1) Oxidation Take 5.0g of oxaliplatin raw material, put it in a 3000mL measuring bottle, add 1000mL of water, and dissolve it by ultrasonic (power: 500W, frequency: 40kHz) for 10 minutes, and fill the bottle with excess oxygen at 30°C. Seal it, let it stand for 1 hour, and let it stand for 10 times with oxygen.

[0050] (2) Preparation of crude product Concentrate the above solution to 500mL under reduced pressure with a Buchi R210 rotary evaporator (temperature: 80°C, vacuum degree: 100mbar, rotation speed: 60 rpm), and evaporate to dryness on a water bath to obtain 5.5g of impurity C crude product .

[0051] (3) Recrystallization Take the crude product of impurity C, add 1000mL of water, heat to 80°C in a water bath, dissolve it with ultrasound (power: 500W, frequency: 40kHz) for 30 minutes, filter, and use Buchi R210 rotary evaporator for the filtrate (temperature: 80°C, vacuum Degree: 100mbar, rotation speed: 60 rpm) concentrated under reduced pressure to 400mL, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com