A kind of anticorrosion marine paint and preparation method thereof

A marine paint and cation technology, applied in the field of coatings, can solve problems such as poor mechanical properties and poor adhesion, and achieve the effects of improving seawater corrosion resistance, improving antifouling performance, excellent water resistance and scrubbing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

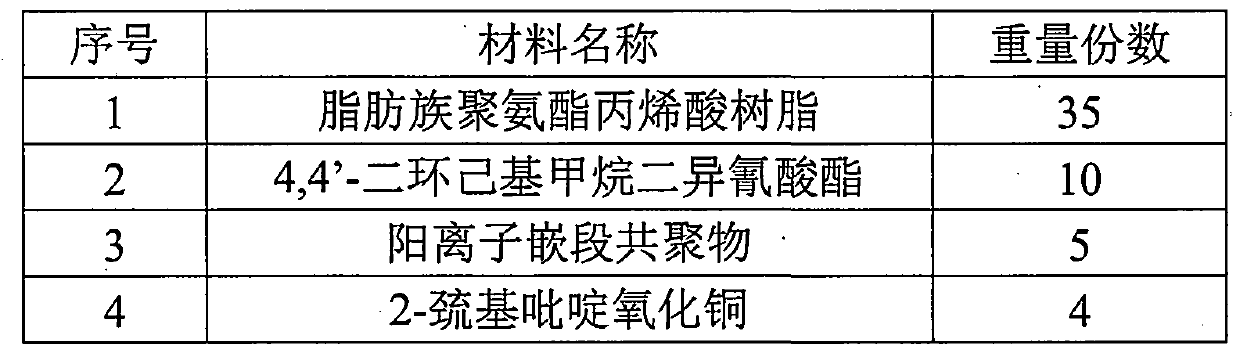

[0019] The raw material formula is shown in the following table:

[0020]

[0021]

[0022] Among them, the median particle size D50 of copper pyrithione oxide is 30-40 μm, the organic solvent is xylene, and the cationic block copolymer is P(MMA) 20 -b-P(METEA) 10 , the particle size of the nano ferric oxide is 20-40nm.

[0023] Preparation method: Add organic solvent, aliphatic urethane acrylic resin, 4,4'-dicyclohexylmethane diisocyanate, cationic block copolymer, N-methyl-2-pyrrole nitrile into a stirrer, stir well and then add Copper pyrithione oxide, cuprous oxide, graphene oxide, nano-ferric oxide, aluminum tripolyphosphate, and high-speed stirring to disperse.

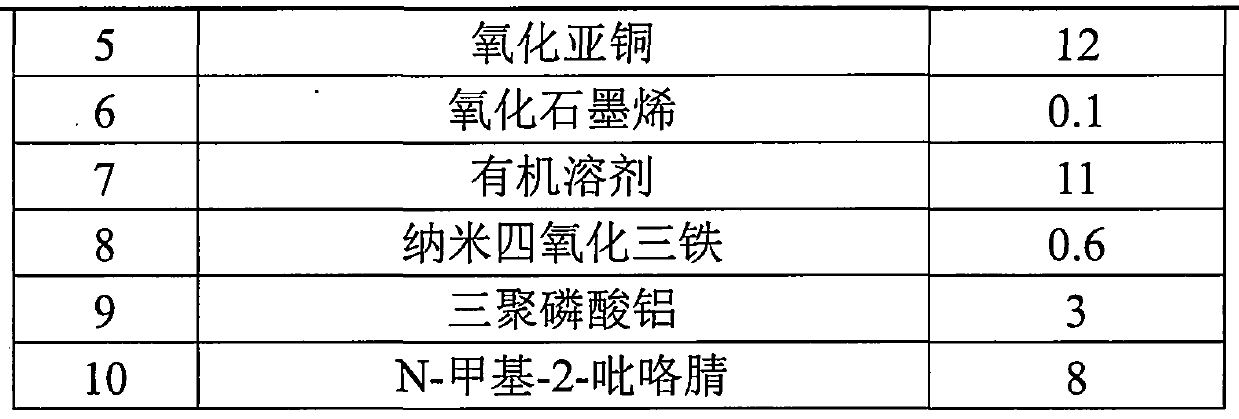

[0024] The performance of the coating that present embodiment obtains is shown in the table below:

[0025]

[0026]

Embodiment 2

[0028] The raw material formula is shown in the following table:

[0029] serial number

parts by weight

1

Aliphatic polyurethane acrylic resin

40

2

4,4'-Dicyclohexylmethane diisocyanate

15

3

cationic block copolymer

7

4

Copper pyrithione oxide

3

5

Cuprous oxide

20

6

Graphene oxide

0.3

7

Organic solvents

14

8

Nano ferric oxide

0.8

9

Aluminum Tripolyphosphate

4

10

N-methyl-2-pyrrole carbonitrile

9

[0030] Among them, the median particle size D50 of copper pyrithione oxide is 30-40 μm, the organic solvent is cyclohexanone, and the cationic block copolymer is P(MMA) 20 -b-P(METEA) 20 , the particle size of the nano ferric oxide is 20-40nm.

[0031] Preparation method: Add organic solvent, aliphatic urethane acrylic resin, 4,4'-dicyclohexylmethane diisocyanate, cationic block copolymer, N-methyl-2-pyrrole nitrile int...

Embodiment 3

[0036] The raw material formula is shown in the following table:

[0037] serial number

parts by weight

1

Aliphatic polyurethane acrylic resin

30

2

4,4'-Dicyclohexylmethane diisocyanate

13

3

cationic block copolymer

9

4

Copper pyrithione oxide

3

5

Cuprous oxide

19

6

Graphene oxide

0.5

7

Organic solvents

15

8

Nano ferric oxide

0.8

9

Aluminum Tripolyphosphate

5

10

N-methyl-2-pyrrole carbonitrile

10

[0038] Among them, the median particle size D50 of copper pyrithione oxide is 30-40 μm, the organic solvent is xylene, and the cationic block copolymer is P(MMA) 20 -b-P(METEA) 30 , the particle size of the nano ferric oxide is 20-40nm.

[0039] Preparation method: Add organic solvent, aliphatic urethane acrylic resin, 4,4'-dicyclohexylmethane diisocyanate, cationic block copolymer, N-methyl-2-pyrrole nitrile into a st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com