Method for whitening agar under assistance of enzymatic method

An agar and enzymatic technology, applied in the field of enzymatic assisted whitening of agar, can solve problems such as environmental hazards, poor diffusion effect, and impact on human health, and achieve the effects of cost saving, reduction in usage, and sustainable development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

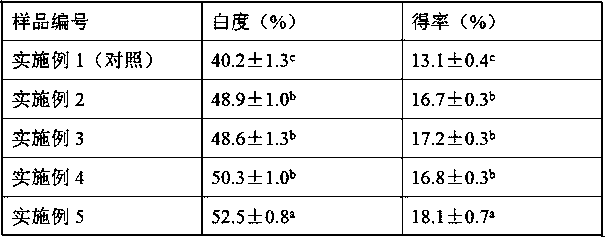

Examples

Embodiment 1

[0027] Step 1. Raw material processing: add 50 g of Gracilaria to rinse with water to remove sand, shells and other impurities;

[0028] Step 2. Alkali treatment: add 7 wt.% lye, the mass-to-volume ratio of material to liquid is 1:20, soak at a constant temperature at 90 °C for 3 h, filter, and rinse with water until neutral;

[0029] Step 3. Acidification treatment: Soak in water at a mass-to-liquid ratio of 1:18, then add 0.12 wt.% disodium edetate, 0.06% oxalic acid, and 0.06% sulfuric acid, treat for 40 minutes, filter, and rinse until neutral ;

[0030] Step 4. Bleaching treatment: Soak in water at a material-to-water mass volume ratio of 1:18, then add 0.25 wt. % sodium hypochlorite solution, process for 40 min, filter, and rinse until neutral;

[0031] Step 5: Boil glue and filter: soak in water at a mass-volume ratio of material to water of 1:12, boil under normal pressure until Gracilaria is completely melted, filter with plate and frame, remove algae residue, and ob...

Embodiment 2

[0035] Step 1. Alkali treatment: After drying and removing impurities, the Jiangli vegetable is added with a concentration of 7% lye, the ratio of solid to liquid is 1:18, soaked at a constant temperature of 85°C for 3 hours, filtered, and rinsed with water until neutral;

[0036] Step 2. Enzyme bleaching treatment: Add water at a material-to-liquid ratio of 1:18, then add 0.01% oxalic acid, adjust the pH value to 4.8-5.0 with acid, and add 0.1% laccase and 0.05% other compound enzymes at a constant temperature. Hydrolyze for 2 h, filter, and rinse until neutral; the complex enzymes are cellulase and laccase.

[0037] Step 3, remove metal ions: add water, the ratio of solid to liquid is the same as step 1, then add 0.012% EDTA disodium metal chelating agent, treat for 2 h, filter, and rinse until neutral;

[0038] Step 4, chemical bleaching treatment: add water with a material-to-liquid ratio of 1:18, then 0.1% sodium hypochlorite solution, process for 20 min, filter, and rins...

Embodiment 3

[0043] Step 1. Alkali treatment: After drying and removing impurity, Jiangli vegetable is added with 7% lye, the ratio of material to liquid is 1:18, soaked at a constant temperature of 85 °C for 3 hours, filtered, and rinsed with clean water until neutral;

[0044] Step 2. Enzyme bleaching treatment: add water at a material-to-liquid ratio of 1:18, then add 0.01% oxalic acid, adjust the pH value to 4.8-5.0 with acid, and add 0.1% laccase and 0.08% other compound enzymes at a constant temperature Hydrolyze for 2 h, filter, and rinse until neutral; the other complex enzyme is xylanase.

[0045] Step 3, remove metal ions: add water, the ratio of solid to liquid is the same as step 1, then add 0.012% EDTA disodium metal chelating agent, treat for 2 h, filter, and rinse until neutral;

[0046]Step 4, chemical bleaching treatment: add water with a material-to-liquid ratio of 1:18, then 0.1% sodium hypochlorite solution, process for 20 min, filter, and rinse until neutral;

[0047]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com