Acrylate coating and preparation method thereof

A technology of acrylate and butyl methacrylate, which is applied in the field of acrylate coating and its preparation, can solve the problems of poor wear resistance, poor chemical resistance, and difficulty in meeting the coating requirements, so as to be less susceptible to moisture corrosion and easy to control , the effect of enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

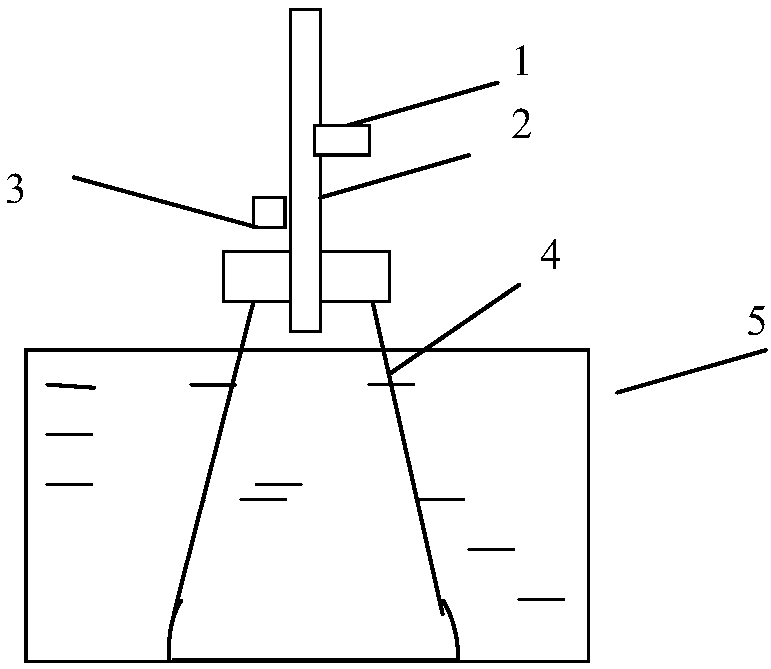

Image

Examples

Embodiment 1

[0027] The steps of preparation are as follows:

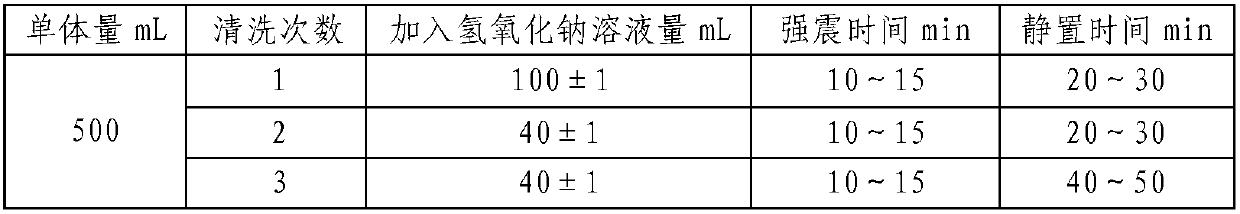

[0028] 1. Cleaning: Put 500mL methyl methacrylate and 500mL butyl methacrylate into a separatory funnel for cleaning. Add 1% sodium hydroxide solution to each 500mL liquid according to the technical conditions in Table 1, and wash it three times under strong shaking conditions;

[0029] Table 1 monomer cleaning technical conditions

[0030]

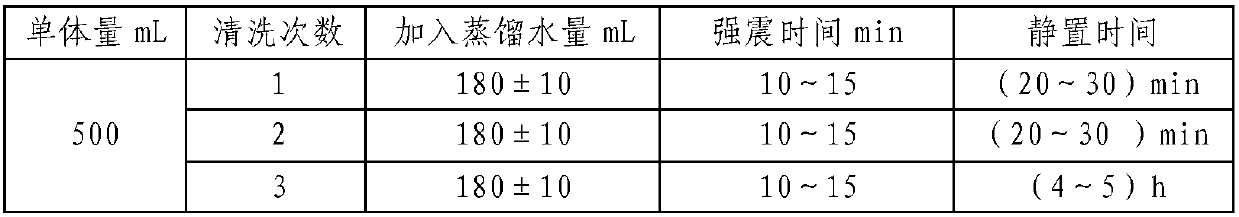

[0031] 2. Remove sodium hydroxide solution: clean the cleaned monomer with distilled water according to the technical conditions in Table 2, and then let the monomer stand for 24 hours to use after cleaning with distilled water;

[0032] Table 2 removes the cleaning technical conditions of sodium hydroxide solution

[0033]

[0034] 3. Polymerization: Weigh 10 g of washed methyl methacrylate, 90 g of butyl methacrylate, and 0.10 g of dibenzoyl peroxide according to the formula, put them into a conical flask, stir to make dibenzoyl peroxide completely dissolved. Connect the conica...

Embodiment 2

[0036] The steps of preparation are as follows:

[0037] 1. Cleaning: Put 500mL methyl methacrylate and 500mL butyl methacrylate into a separatory funnel for cleaning. For every 500mL of liquid, add 1% sodium hydroxide solution according to the technical conditions in Table 1, and wash it three times under strong shaking conditions;

[0038] 2. Remove the sodium hydroxide solution: clean the cleaned monomer with distilled water according to the technical conditions in Table 2, and then let the monomer stand for 24 hours to use after cleaning with distilled water;

[0039] 3. Polymerization: Take 12g of washed methyl methacrylate, 91g of butyl methacrylate, and 0.11g of dibenzoyl peroxide according to the formula, put them into a conical flask, stir to make dibenzoyl peroxide completely dissolved. Connect the conical flask to a reflux condenser, place it in a constant temperature water bath at 80°C, shake the conical flask, take out the conical flask every 60 minutes, cool it...

Embodiment 3

[0041] The steps of preparation are as follows:

[0042] 1. Cleaning: Put 500mL methyl methacrylate and 500mL butyl methacrylate into a separatory funnel for cleaning. Add 1% sodium hydroxide solution to each 500mL liquid according to the technical conditions in Table 1, and wash it three times under strong shaking conditions;

[0043] 2. Remove the sodium hydroxide solution: clean the cleaned monomer with distilled water according to the technical conditions in Table 2, and then let the monomer stand for 24 hours to use after cleaning with distilled water;

[0044] 3. Polymerization: Weigh 11g of washed methyl methacrylate, 92g of butyl methacrylate, and 0.12g of dibenzoyl peroxide according to the formula, put them into a conical flask, stir to make dibenzoyl peroxide completely dissolved. Connect the conical flask to a reflux condenser, place it in a constant temperature water bath at 85°C, shake the conical flask, take out the conical flask every 55 minutes, and after co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com