A kind of preparation technology of low carbon deep drawing steel

A preparation process and deep drawing technology, applied in the field of low carbon deep drawing steel preparation process, can solve problems such as high carbon dioxide emissions, unstable molten steel quality, large converter lining erosion, etc., to achieve high molten steel yield, high molten steel Low degree of oxidation, the effect of avoiding peeling defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

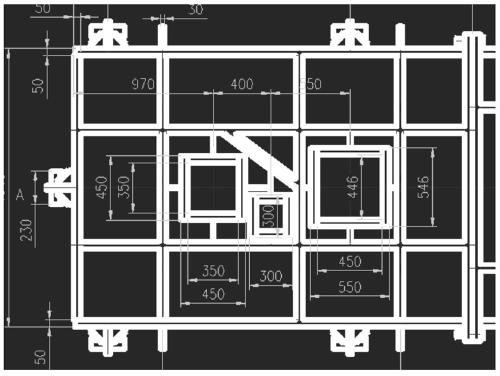

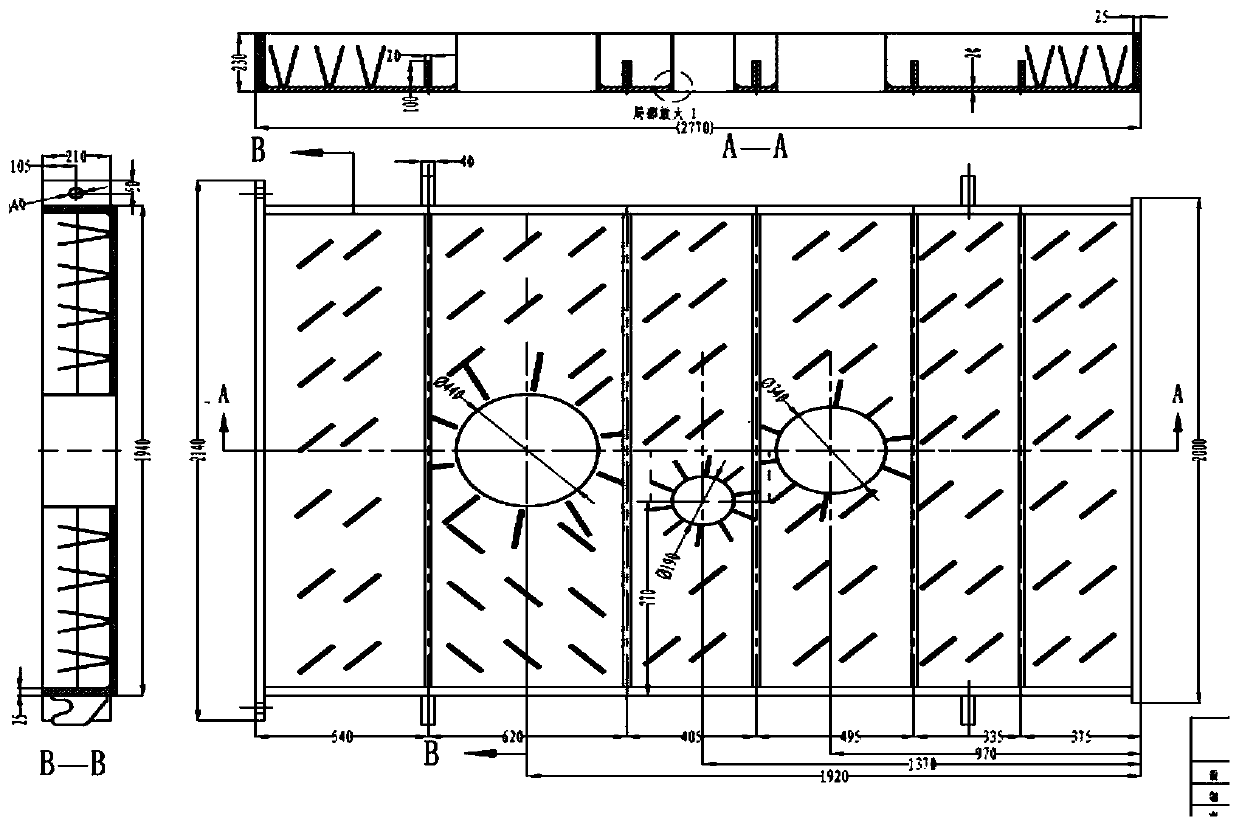

[0087] The preparation of low-carbon deep-drawing steel is carried out according to the following process flow:

[0088] Converter smelting→argon station (ladle slag reformation)→refining (RH)→slab continuous casting (mold metallurgy + mold electromagnetic braking)→steel billets are directly put into the furnace for rolling.

[0089] Converter smelting process: The converter adopts top-bottom double blowing, so that the end point [P]≤0.010%, the end point [N]≤0.0015%, the blowing is successful in pulling carbon once, and the content of the end point [C] is controlled between 0.06-0.08%. The [O] content is 200-400ppm, and the tapping temperature is controlled between 1660-1680°C. Through automatic steelmaking technology, the structure of steel materials and auxiliary materials is optimized to ensure that the composition and temperature at the end of the converter are within the required range. Tapping is operated by a slag-stopping car to reduce the amount of slag, and control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com