Composite disintegrant system for oral solid preparation and oral solid preparation containing composite disintegrant system

A compound disintegrant and solid preparation technology, which is applied in the direction of medical preparations containing active ingredients, medical preparations with non-active ingredients, pill delivery, etc., and can solve problems such as viscous active substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

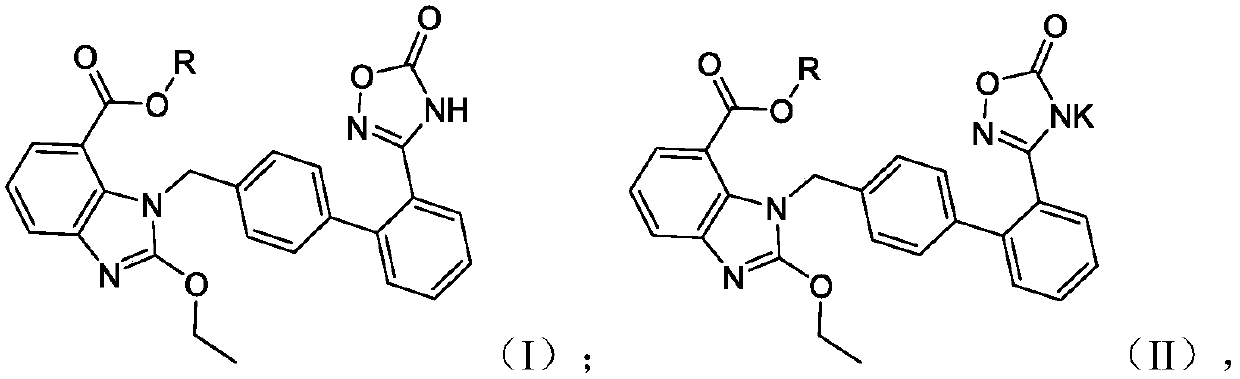

[0081] Embodiment 1: Preparation of QR01019K

[0082] Dissolve QR01019 (1.0g) in dichloromethane (5ml), stir at room temperature to form a solution, add potassium phthalimide (0.27g) to the solution, keep it warm for 4 hours, cool to -50°C, filter, The solid obtained by spin-drying the solvent is amorphous QR01019K.

[0083] Melting point: 135-145°C.

[0084] MS / HRMS m / z: 717[M+H] + ;677[M-K] - .

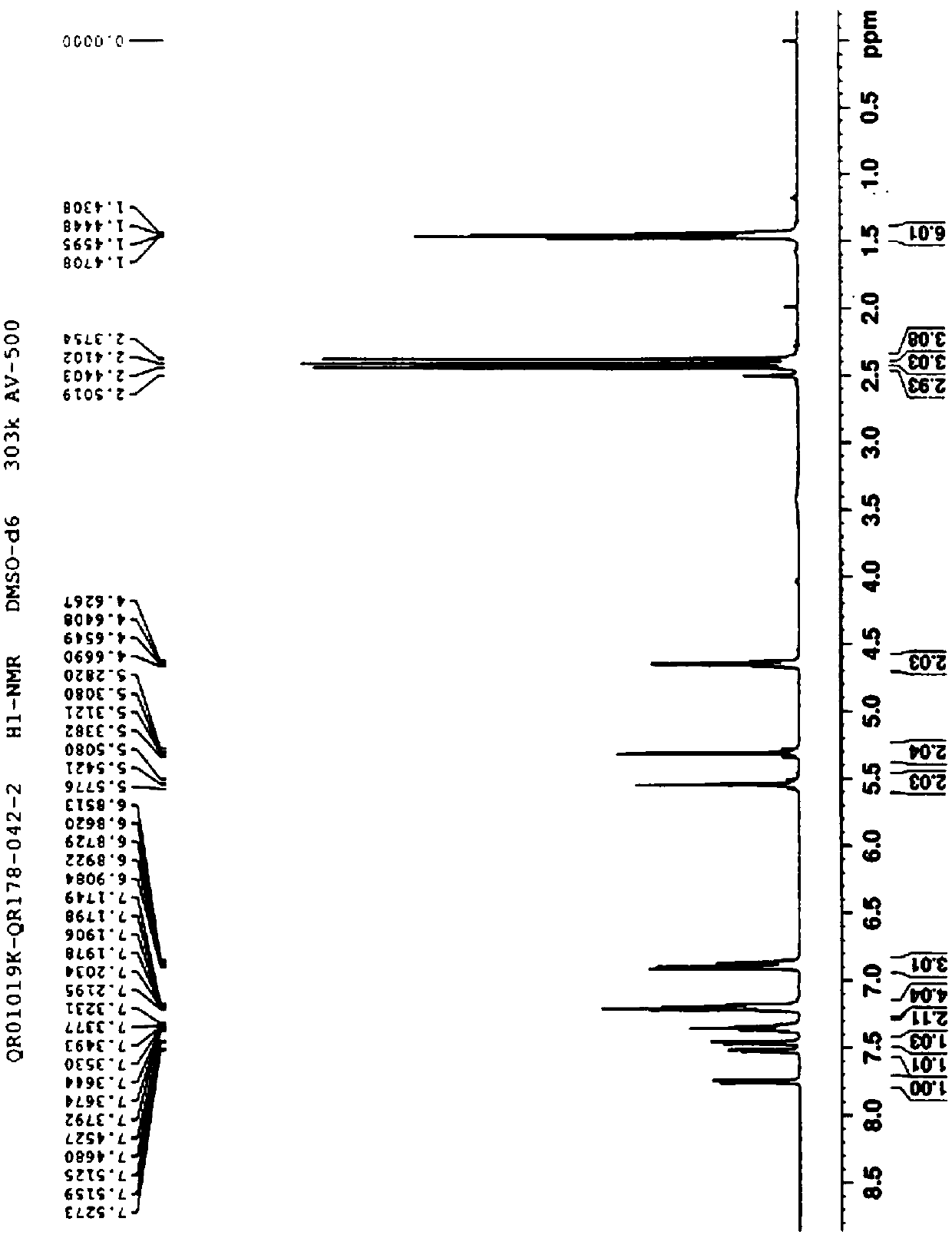

[0085] 1 H-NMR (400MHz, DMSO-d 6)δ: 1.44(t, 3H), 1.46(t, 3H), 2.38(s, 3H), 2.41(s, 3H), 2.44(s, 3H), 4.64(q, 2H), 5.29(d, 1H ), 5.32(d, 1H), 5.52(d, 1H), 5.56(d, 1H), 6.86(q, 1H), 6.90(d, 2H), 7.18(m, 2H), 7.22(d, 2H) , 7.33 (m, 1H), 7.36 (m, 1H), 7.46 (d, 1H), 7.52 (dd, 1H), 7.75 (d, 1H).

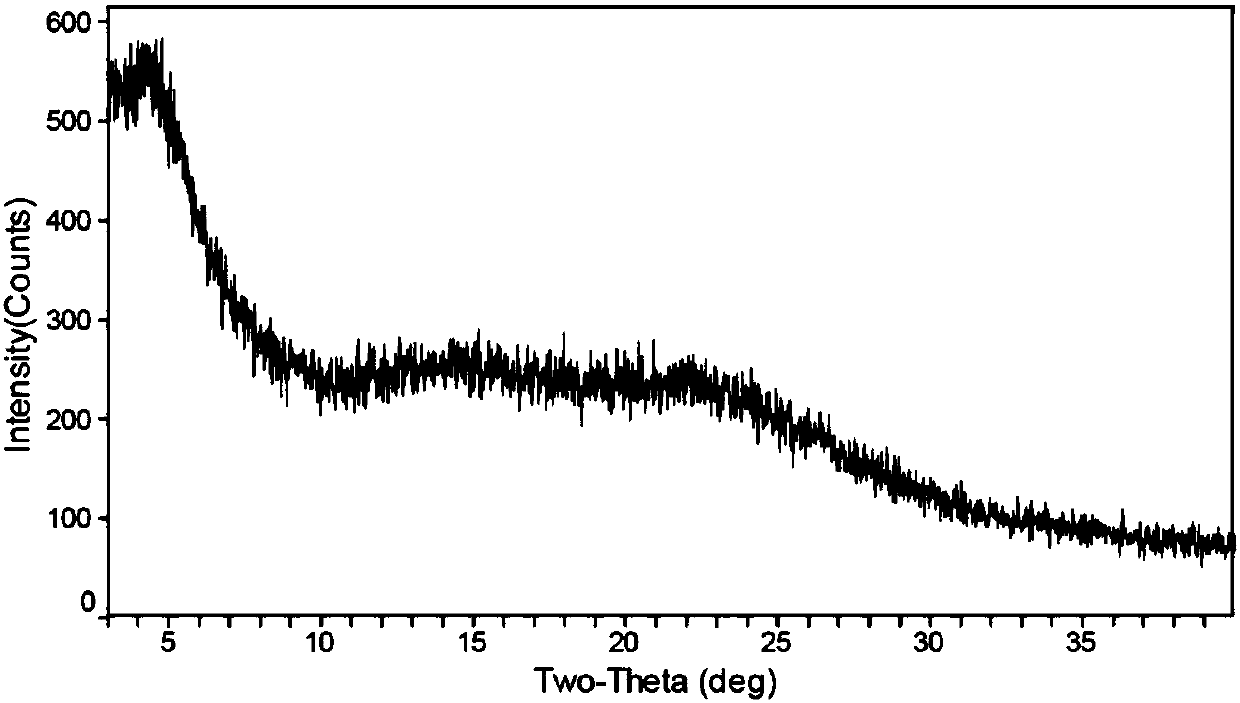

[0086] H-NMR spectrum and X-ray powder diffraction spectrum are shown in figure 1 and figure 2 .

Embodiment 2

[0087] Example 2: Antihypertensive efficacy test of QR01019K on spontaneously hypertensive rats

[0088] Spontaneously hypertensive rats aged 12 weeks (hereinafter referred to as SHR, purchased from Beijing Weitong Lihua Experimental Animal Technology Co., Ltd.) were anesthetized by intraperitoneal injection of 2.5% sodium pentobarbital. The blood pressure sensing catheter was inserted into the abdominal aorta, the implant was fixed on the abdominal wall, and the postoperative daily care was performed after suturing. Animals whose systolic blood pressure exceeded 160mm Hg were selected into groups, with 8 animals in each group, 3 groups in total. The control group was given 0.5% sodium carboxymethylcellulose (hereinafter referred to as CMC-Na); the OR01019 group and the QR01019K group were dissolved in 0.5% CMC-Na, and the dosage was based on the effective dose of 1 mg / kg azilsartan. The drug volume is 4mL / kg, all administered by intragastric administration, with the systolic...

Embodiment 3

[0100] Embodiment 3: preparation and disintegration experiment of oral solid preparation

[0101] Tablets of Preparation Examples 1-11 and Comparative Examples 1-11 were respectively prepared according to the following three preparation methods, and the differences in prescription composition, tablet hardness and tablet weight of each preparation example and Comparative Examples are shown in Table 3 below.

[0102] Preparation examples 1, 7, 8 and 9, comparative examples 1, 7, 8 and 9 adopt the powder compression method: select 60 mesh sieves according to the material properties, and the material is sieved for subsequent use (in preparation example 7 and comparative example 7, active The ingredients and excipients are sieved together, and the disintegrating agent and the disintegrating agent are mixed and sieved for subsequent use; the remaining preparation examples and comparative examples are sieved separately); the active ingredients, excipients, disintegrants, There is no ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com