Preparation method and application of graphene oxide polymer continuous bed and method for separating and enriching phytosterol

A polymer and graphene technology, applied in steroids, chemical instruments and methods, separation methods, etc., can solve the problems of unfriendly environment, cumbersome steps, low recovery rate, etc., and achieve the improvement and expansion of specific surface area and pore structure. Scope of application, simple effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Mix 0.8 mg graphene oxide (GO), 20 mg benzoyl peroxide, 20 mg polyvinylpyrrolidone (PVP), 0.36 mL octene (C8), 0.36 mL triethylene glycol diacrylate (TEGDMA), 0.2 mL n-propanol , 0.16mL lauryl alcohol, and ultrasonically disperse for more than 30min. After the dispersion is uniform, add 200μL of N,N-dimethylaniline, mix thoroughly, and ultrasonically remove air bubbles. In the chromatographic column tube, after reacting in a water bath at 30°C for 2.5 hours, install the column head at both ends of the stainless steel chromatographic column tube, and then connect it to the high-performance liquid chromatography pump, use methanol as the mobile phase to remove the porogen in the column body and other unused porogens. The reacted soluble matter is washed away to obtain a continuous bed of graphene oxide modified organic polymer.

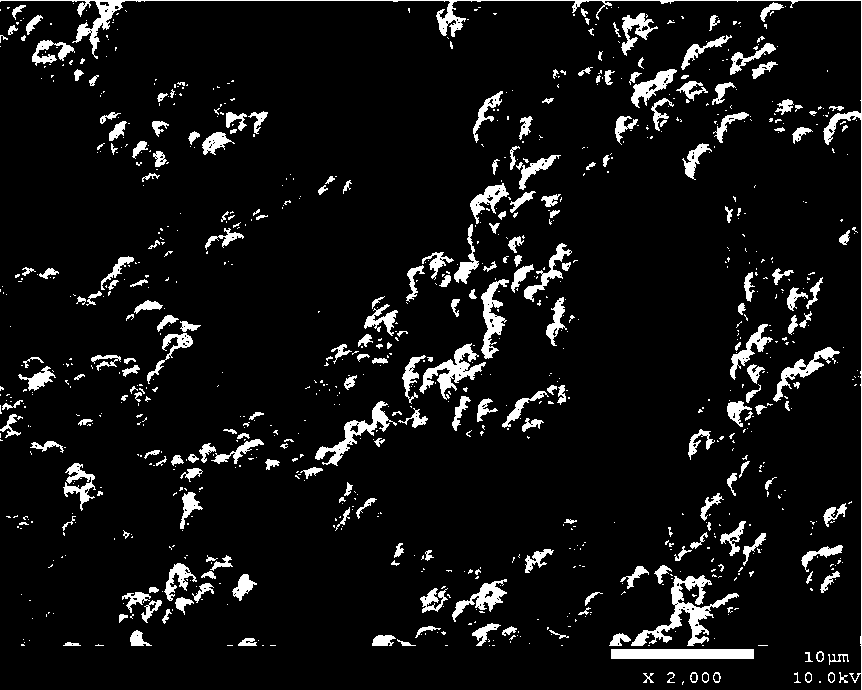

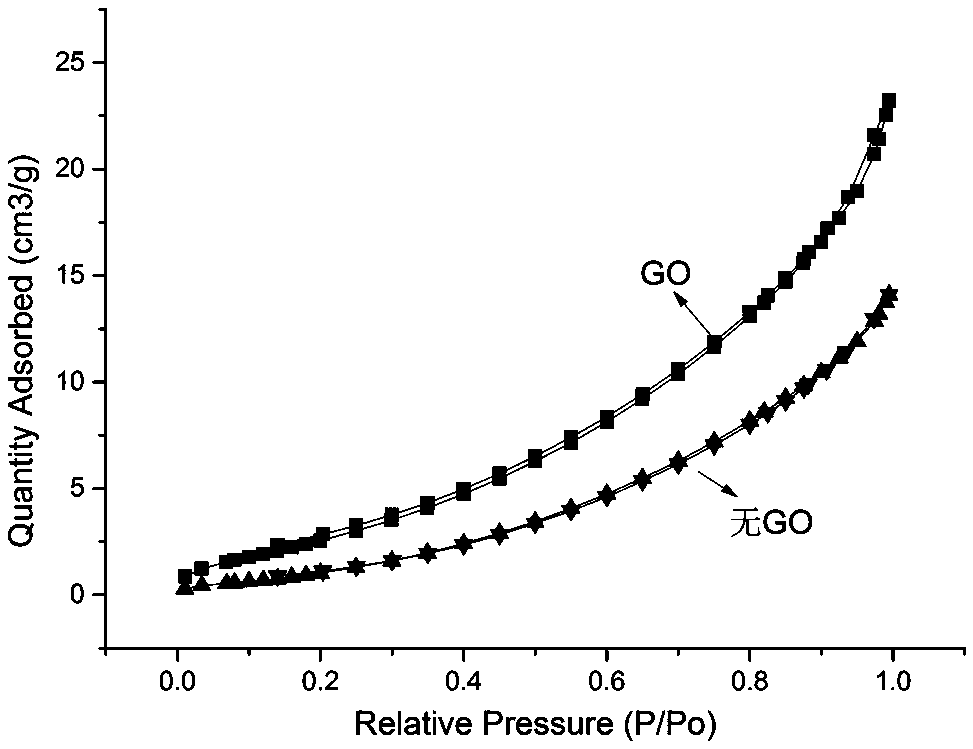

[0034] The microscopic morphology of the prepared continuous bed was observed with a scanning electron microscope, and the obtained results were...

Embodiment 2

[0039]Mix 0.1mg graphene oxide, 20mg benzoyl peroxide, 40mg polyvinylpyrrolidone, 0.30mL octene, 0.30mL triethylene glycol diacrylate, 0.2mL n-propanol, 0.16mL lauryl alcohol, and ultrasonically disperse for more than 30min. After dispersing evenly, add 200 μL of N,N-dimethylaniline, mix thoroughly, and ultrasonically remove air bubbles, pour the mixture into a 50 mm×4.6 mm I.D. stainless steel column tube, and react in a water bath at 30°C for 2.5 After h, a column head is installed at both ends of the stainless steel chromatographic column tube, and then connected to a high performance liquid chromatography pump, and other unreacted soluble substances such as porogens in the column are washed away with methanol as the mobile phase, to obtain Continuous beds of graphene oxide-modified organic polymers.

Embodiment 3

[0041] Mix 0.4mg graphene oxide, 20mg benzoyl peroxide, 40mg polyvinylpyrrolidone, 0.36mL octene, 0.36mL triethylene glycol diacrylate, 0.16mL n-propanol, 0.14mL lauryl alcohol, and ultrasonically disperse for more than 30min. After dispersing evenly, add 200 μL of N,N-dimethylaniline, mix well, and ultrasonically remove air bubbles, then pour the mixture into a 50 mm×4.6 mm I.D. , install the column head at both ends of the stainless steel chromatographic column tube, then connect it to the high performance liquid chromatography pump, use methanol as the mobile phase to wash away the porogen, solvent and other unreacted soluble substances in the column body, and obtain Continuous beds of graphene oxide-modified organic polymers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com