Recovery processing system and method for household garbage incineration fly ash

A technology of domestic waste incineration and fly ash recovery, applied in the field of environmental protection, can solve the problems of secondary pollution, high recovery cost and low efficiency, and achieve the effect of improving work efficiency and ensuring uniqueness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

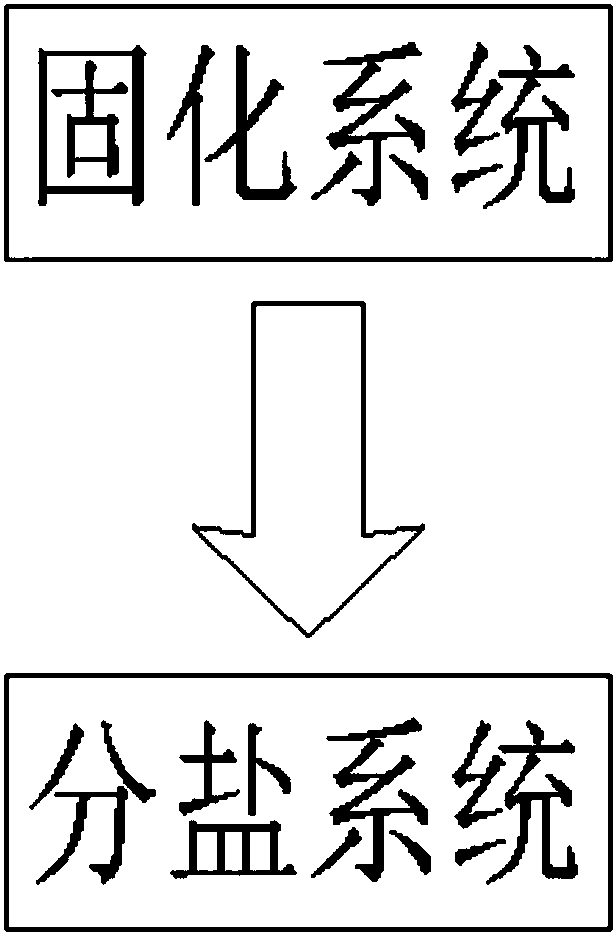

[0035] Such as figure 1 as shown, figure 1 It shows the waste incineration fly ash recovery and treatment system provided by the embodiment of the present invention, the system includes a solidification system and a salt separation system, and the waste incineration fly ash is processed continuously through the solidification system and the salt separation system, and finally forms an easy-to-recycle substances and non-polluting emissions.

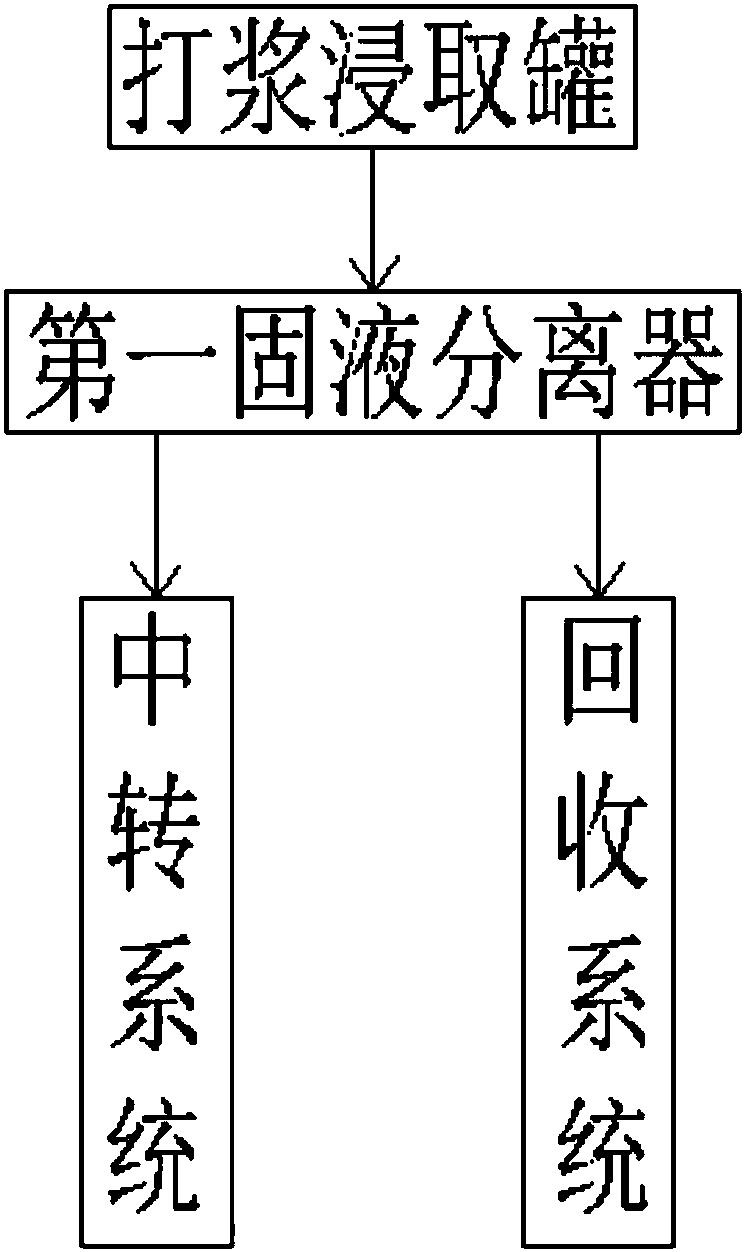

[0036] Such as figure 2 As shown, the solidification system includes a beating leaching tank, the beating leaching tank is connected to the first solid-liquid separator, the solid phase outlet and the liquid phase outlet of the first solid-liquid separator are respectively connected to the recovery system and the transfer system, and the transfer system is connected to the salt separation system. system.

[0037] Among them, the drying equipment is mainly to dry and screen the solid residue, and transport it to the clinker calcination ...

Embodiment 2

[0052] Such as Figure 6 as shown, Figure 6 Shown is the domestic waste incineration fly ash recovery and treatment method provided by the embodiment of the present invention, including the following steps:

[0053] S1. Raw liquid separation: import waste incineration fly ash into the beating and leaching tank through a screw feeder, inject water into the beating and leaching tank, stir to form a raw liquid, and the raw liquid is introduced into the first solid-liquid separator through the pump body; the first solid-liquid The separated solids in the separator are introduced into the gradient beating equipment of the recovery system, and the separated mother liquor is introduced into the transfer tank of the transfer system, and the transfer tank is connected to the heavy metal removal equipment;

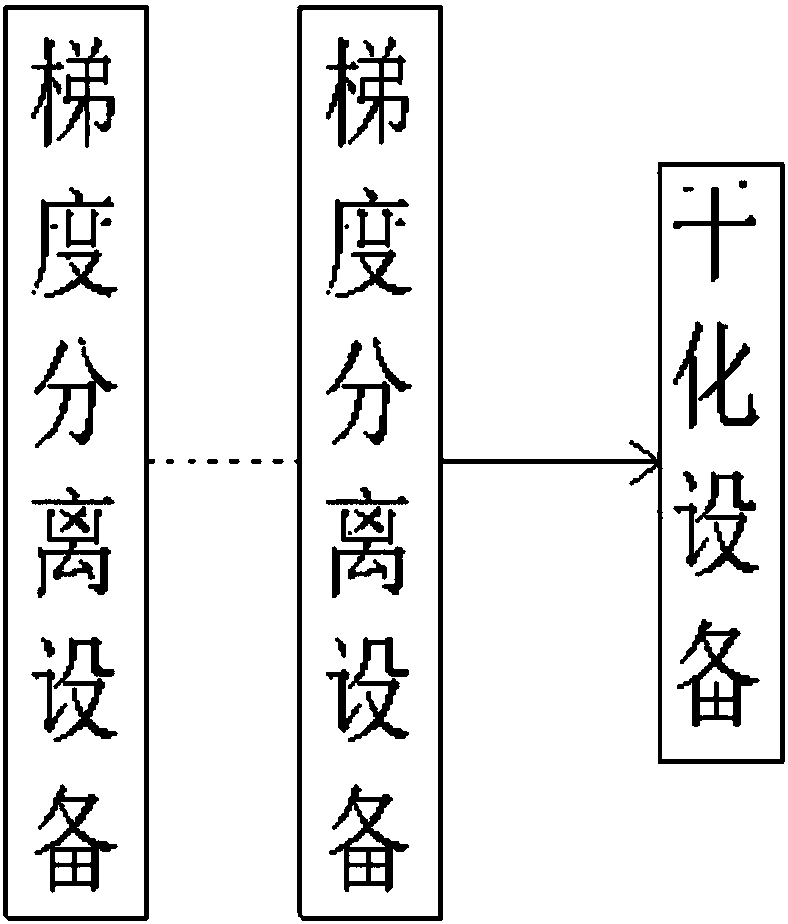

[0054] S2. Post-treatment of the solid after the separation of the raw liquid: the gradient beating tank dilutes the solid again, and then imports it into the circulating gradient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com