Wax solvent for cleaning steel pieces or copper pieces and preparation method of wax solvent

A technology for removing wax water and copper parts, applied in the field of metal surface treatment, can solve the problems of substrate corrosion, unenvironmental protection, poor anti-rust performance of metal products, etc. The effect of the wax effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

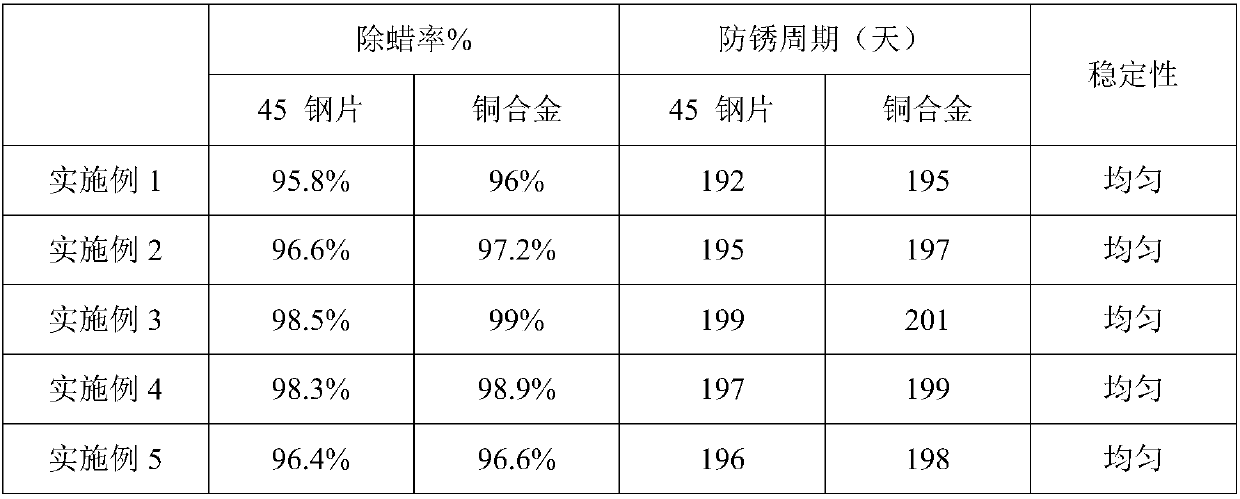

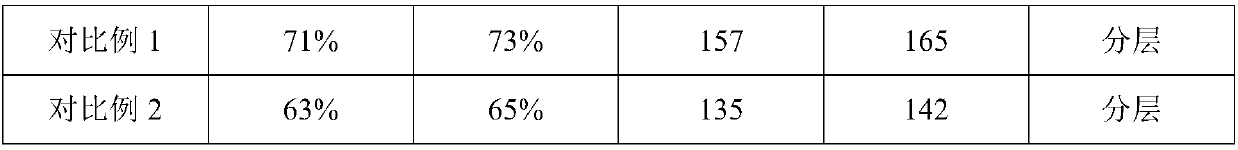

Examples

Embodiment 1

[0025] Weigh the following raw materials in parts by weight: 15 parts of diethylenetriamine, 8 parts of monoethanolamine, 4 parts of triethanolamine, 10 parts of 6502, 2 parts of methanol, 15 parts of oleic acid, 2 parts of NP-10, 10 parts of water, and set aside .

[0026] Prepare the above raw materials that have been weighed according to the following method:

[0027] (1) Mix diethylenetriamine, monoethanolamine, triethanolamine, and oleic acid, heat to 160°C, stir for 30 minutes, and cool to room temperature;

[0028] (2) coconut oil fatty acid diethanolamide, methyl alcohol, nonylphenol polyoxyethylene ether are added in the mixed solution that step (1) obtains, stir;

[0029] (3) Add water to the mixed solution obtained in step (2), and stir evenly to obtain a wax-removing water for cleaning iron and steel parts or copper parts.

Embodiment 2

[0031] Weigh the following raw materials in parts by weight: 17 parts of diethylenetriamine, 10 parts of monoethanolamine, 6 parts of triethanolamine, 650212 parts, 4 parts of methanol, 15 parts of oleic acid, 4 parts of NP-10, 12 parts of water, and set aside.

[0032] Prepare the above raw materials that have been weighed according to the following method:

[0033] (1) Mix diethylenetriamine, monoethanolamine, triethanolamine, and oleic acid, heat to 170°C, stir for 25 minutes, and cool to room temperature;

[0034] (2) coconut oil fatty acid diethanolamide, methyl alcohol, nonylphenol polyoxyethylene ether are added in the mixed solution that step (1) obtains, stir;

[0035] (3) Add water to the mixed solution obtained in step (2), and stir evenly to obtain a wax-removing water for cleaning iron and steel parts or copper parts.

Embodiment 3

[0037] Weigh the following raw materials in parts by weight: 20 parts of diethylenetriamine, 12 parts of monoethanolamine, 8 parts of triethanolamine, 650215 parts, 5 parts of methanol, 20 parts of oleic acid, 6 parts of NP-10, 14 parts of water, and set aside.

[0038] Prepare the above raw materials that have been weighed according to the following method:

[0039] (1) Mix diethylenetriamine, monoethanolamine, triethanolamine, and oleic acid, heat to 180°C, stir for 20 minutes, and cool to room temperature;

[0040] (2) coconut oil fatty acid diethanolamide, methyl alcohol, nonylphenol polyoxyethylene ether are added in the mixed solution that step (1) obtains, stir;

[0041] (3) Add water to the mixed solution obtained in step (2), and stir evenly to obtain a wax-removing water for cleaning iron and steel parts or copper parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com