Planomiller control system

A control system and gantry milling machine technology, applied in the field of machinery, can solve the problems of high maintenance frequency, poor reliability of machine tools, and inability to give full play to large machine tools, and achieve the effects of easy operation, simplified structure, and improved anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

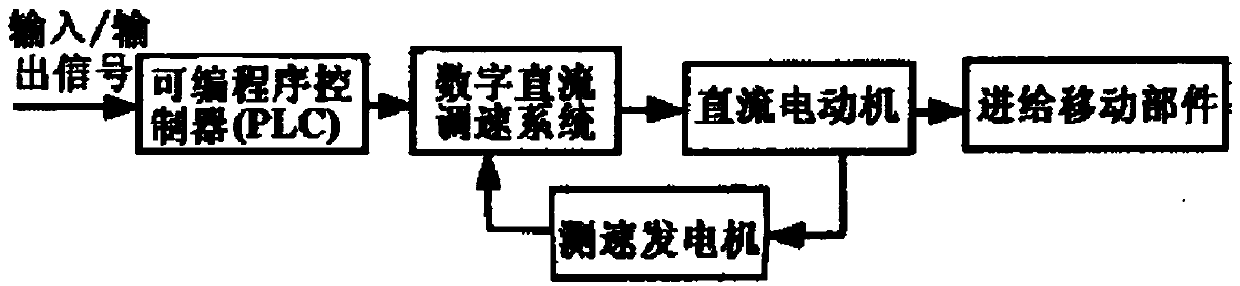

[0013] Such as figure 1 , under the premise of keeping the mechanical transmission system and operation mode of the original X2010A gantry milling machine unchanged, in view of the characteristics of the machine tool and the problems existing in the control system, the control system uses a programmable logic controller (PLC) as the main controller to coordinate The action between the moving parts replaces the relay-contactor control circuit, and replaces the thyristor rectifier system with a digital DC speed control device.

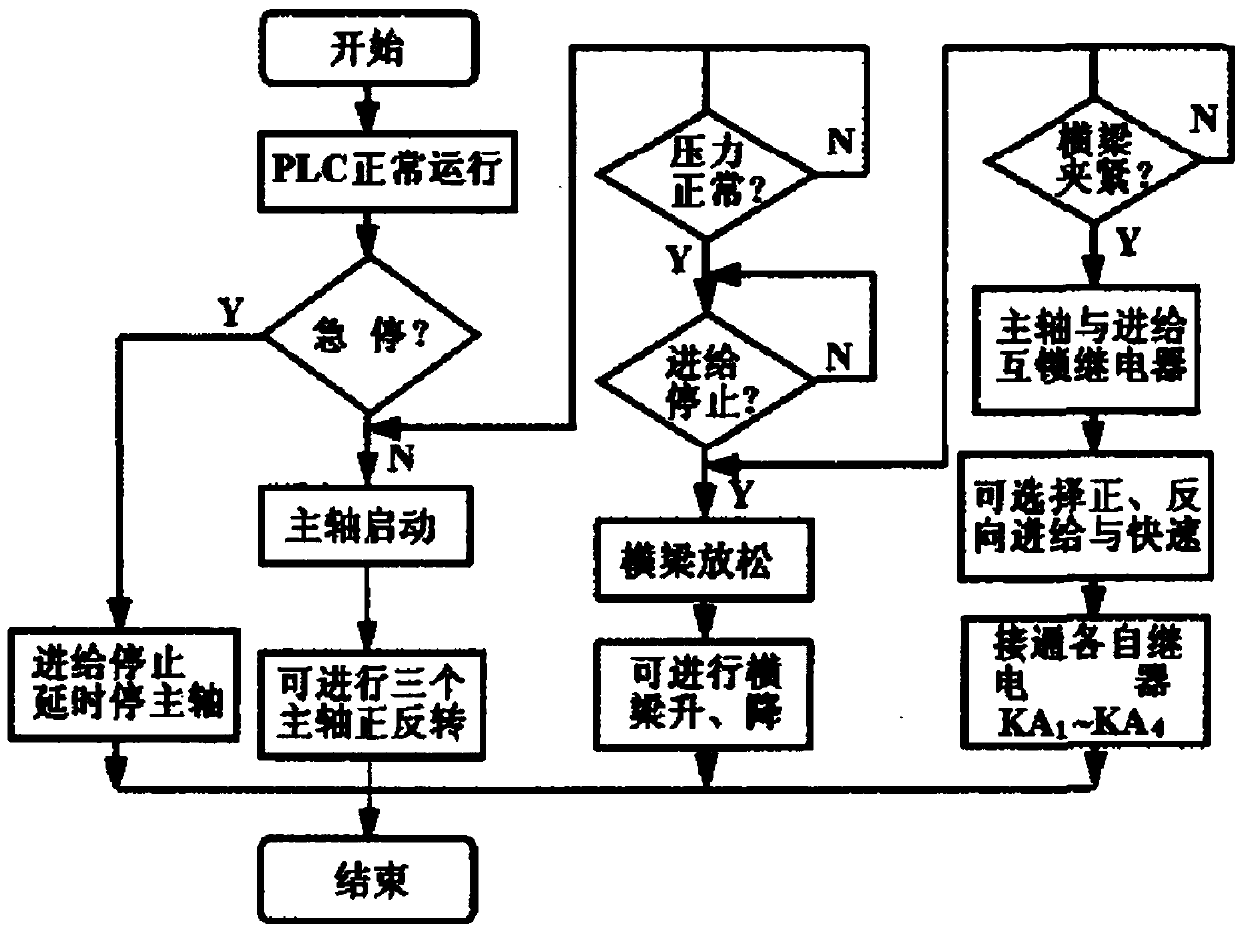

[0014] Such as figure 2 , The main movement of the gantry milling machine includes the rotational movement of the three spindles, the feed movement of the table and the three spindles, and the lifting movement of the beam. Since the control relationship between the start and stop of the hydraulic pump, the selection switch of the worktable and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com