Graphene and ferroferric oxide dual-coated nanometer silicon composite material, preparation method thereof and application thereof in lithium ion batteries

A technology of ferroferric oxide and composite materials, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problem of reduction of electronic contact points and capacity, inability to form stable SEI film, and low coulombic efficiency and capacity issues, to achieve good cycle performance, improve electrochemical stability, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Graphite treatment: Weigh 12.5g of expandable graphite, 50g of potassium ferrate, and 625g of zirconium balls (grinding medium), add them to the ball mill jar, add a sealing ring, ball mill at 400rpm for 48h, pour the obtained sample into water, Then, excess dilute nitric acid (4.8 mol / L) was added for washing, filtered, and dried at 60° C. for 12 hours to obtain graphene nanosheets.

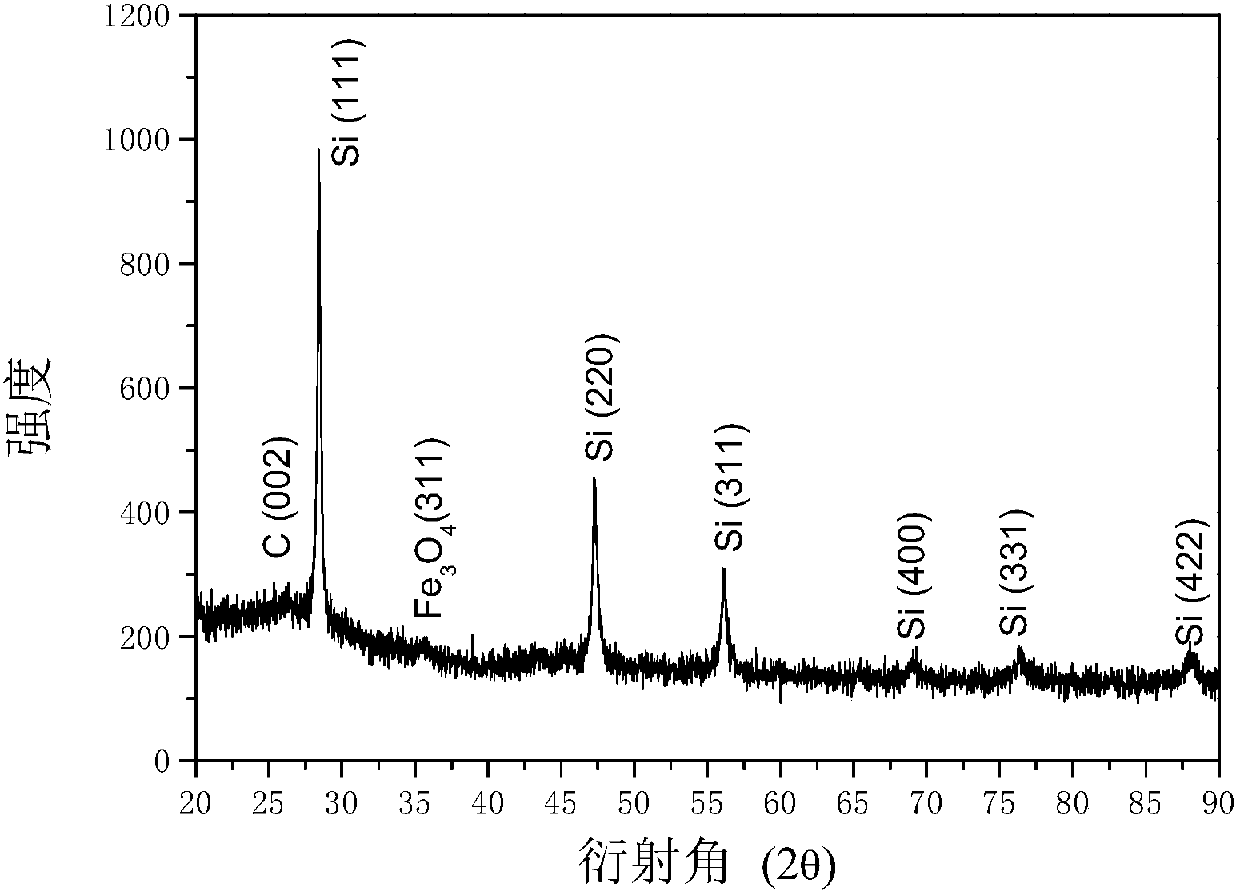

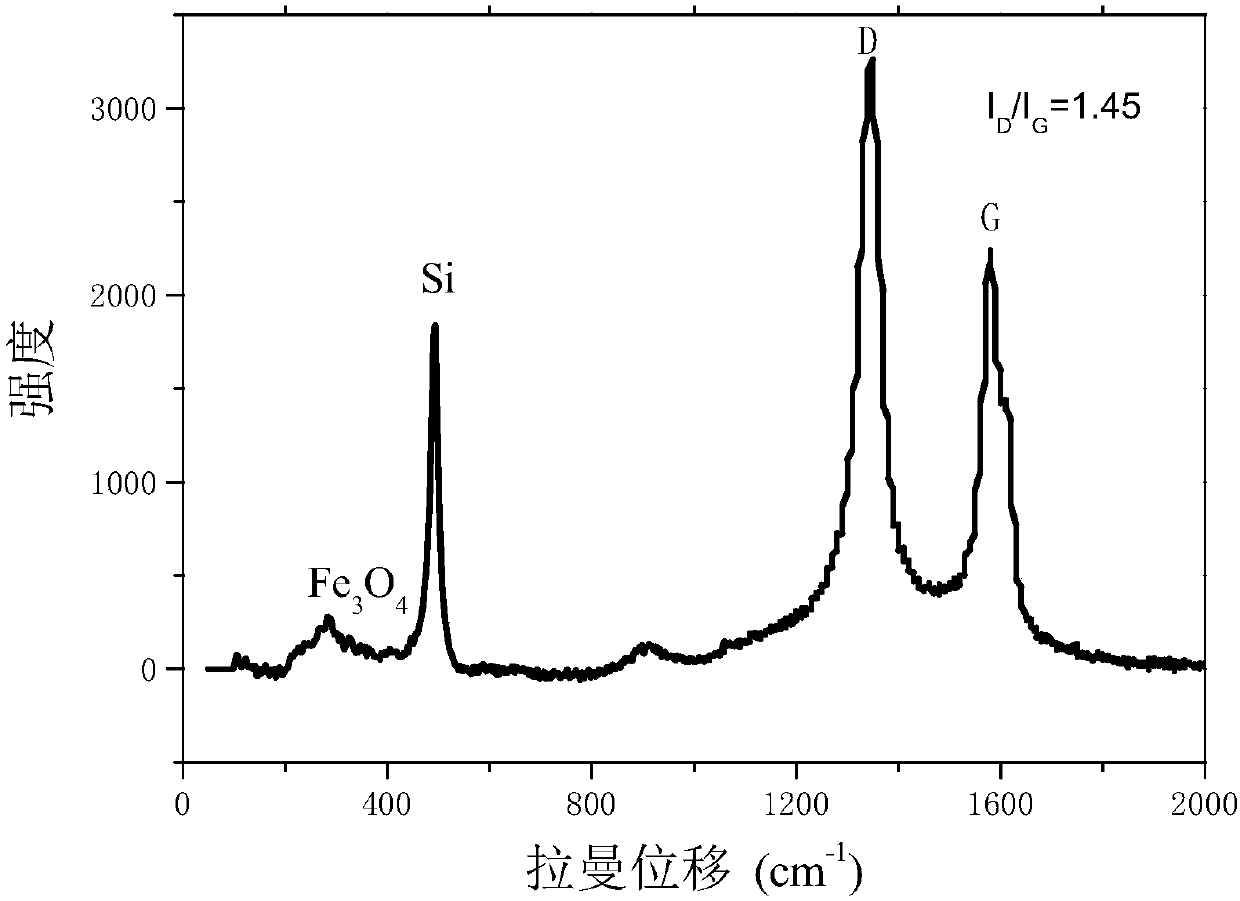

[0037] 2. Preparation of nano-silicon composite material coated with graphene and ferroferric oxide: Weigh 1g of silicon powder, 18g of graphene nanosheets, 1g of potassium ferrate, and 100g of zircon (grinding medium) in turn, add to the ball mill jar, add The upper sealing ring was ball milled at 1000rpm for 5h, and the obtained sample was filtered through a sieve to remove zirconium balls, then filtered, washed, and dried at 60°C for 12h to obtain a nano-silicon composite material double-coated with graphene and ferric oxide.

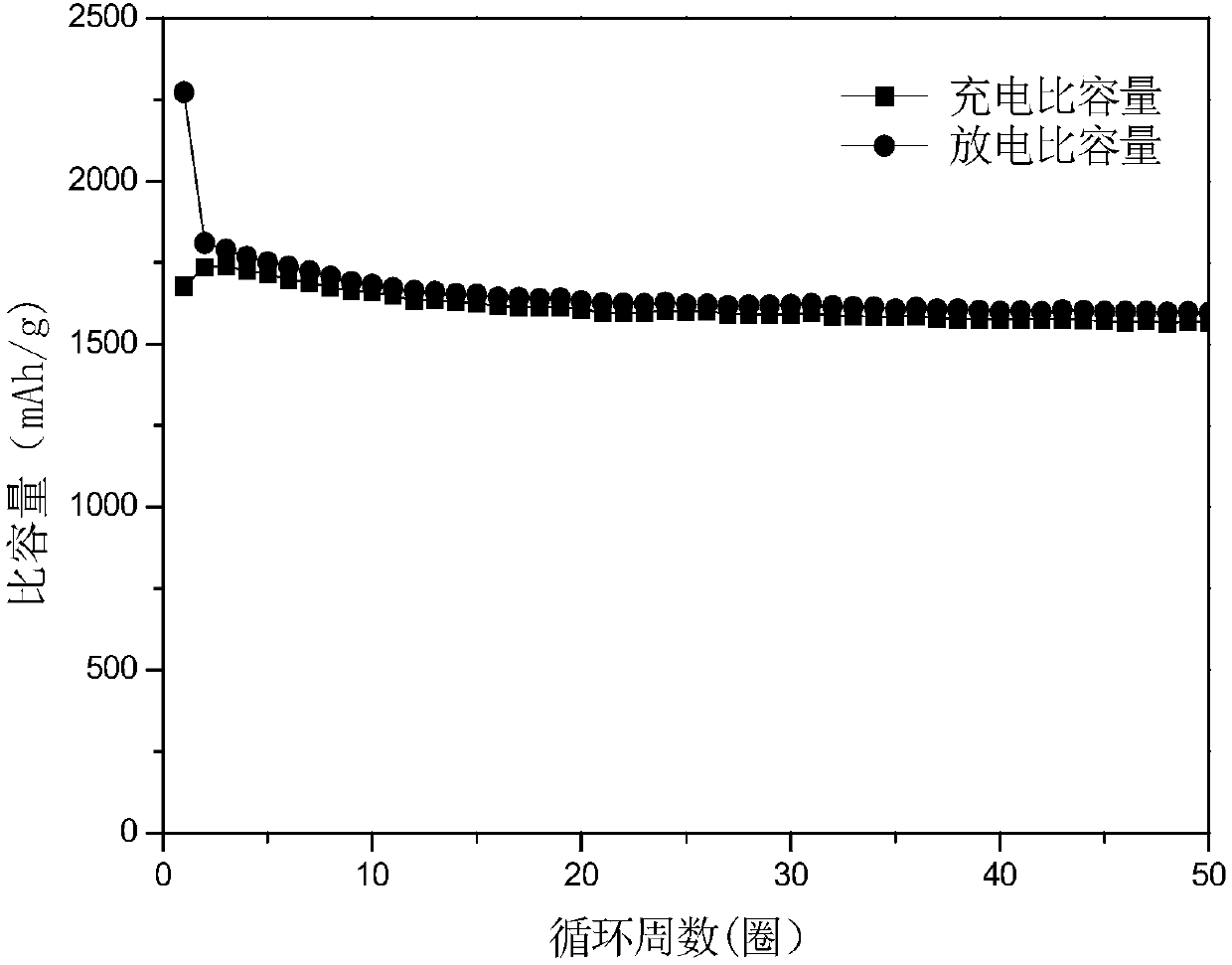

[0038] Take by weighing 0.2g of the graphene and iron f...

Embodiment 2

[0040]1. Graphite treatment: Weigh 12.5g of expandable graphite, 50g of potassium ferrate, and 625g of zirconium balls (grinding medium), add them to the ball mill jar, add a sealing ring, ball mill at 400rpm for 48h, pour the obtained sample into water, Then, excess dilute nitric acid (4.8 mol / L) was added for washing, filtered, and dried at 60° C. for 12 hours to obtain graphene nanosheets.

[0041] 2. Preparation of nano-silicon composite material coated with graphene and ferroferric oxide: Weigh 1g of silicon powder, 6g of graphene nanosheets, 13g of potassium ferrate, and 200g of zircon (grinding medium) in turn, add to the ball mill jar, add The upper sealing ring was ball milled at 800rpm for 10h, and the obtained sample was filtered through a sieve to remove zirconium balls, then filtered, washed, and dried at 60°C for 12h to obtain a nano-silicon composite material double-coated with graphene and ferroferric oxide.

[0042] Take by weighing 0.2g of the graphene and ir...

Embodiment 3

[0044] 1. Graphite treatment: Weigh 12.5g of expandable graphite, 50g of potassium ferrate, and 625g of zirconium balls (grinding medium), add them to the ball mill jar, add a sealing ring, ball mill at 400rpm for 48h, pour the obtained sample into water, Then, excess dilute nitric acid (4.8 mol / L) was added for washing, filtered, and dried at 60° C. for 12 hours to obtain graphene nanosheets.

[0045] 3. Preparation of nano-silicon composite material coated with graphene and ferroferric oxide: Weigh 2g of silicon powder, 14g of graphene nanosheets, 4g of potassium ferrate, and 300g of zircon (grinding medium) in turn, add to the ball mill jar, add The upper sealing ring was ball milled at 600rpm for 20h, and the obtained sample was filtered through a sieve to remove zirconium balls, then filtered, washed, and dried at 60°C for 12h to obtain a nano-silicon composite material double-coated with graphene and ferric oxide.

[0046] Take by weighing 0.2g of the graphene and iron f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com