Silicon-based integrated tunable laser structure and control method thereof

A tunable laser, silicon-based technology, applied in the field of lasers, can solve the problems of low integration, unfavorable industrial processing and production, large volume, etc., and achieve the effects of high integration, high space utilization efficiency, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

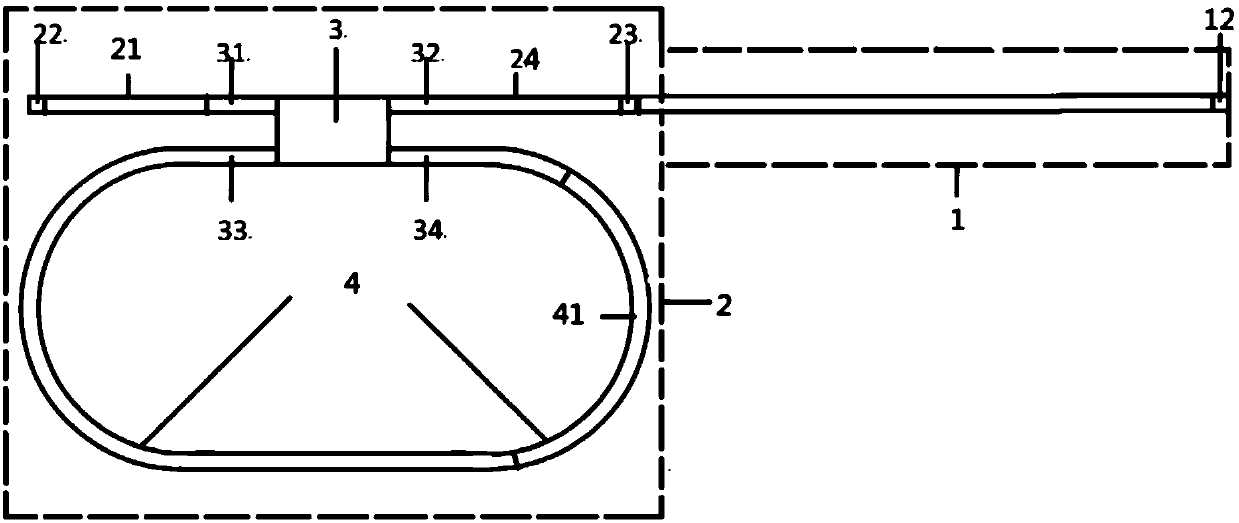

[0050] Embodiment 1 of the present invention provides a silicon-based integrated tunable laser structure, such as figure 2 As shown, it includes: a silicon-based microring resonator 101, a backlight detector 102, and a silicon-based coupling output waveguide 103 are fabricated on a silicon substrate 106. For example, the above-mentioned fabrication of a silicon-based A microring resonator 101 , a backlight detector 102 and a silicon-based outcoupling waveguide 103 . In an embodiment of the present invention, the tunable laser structure further includes:

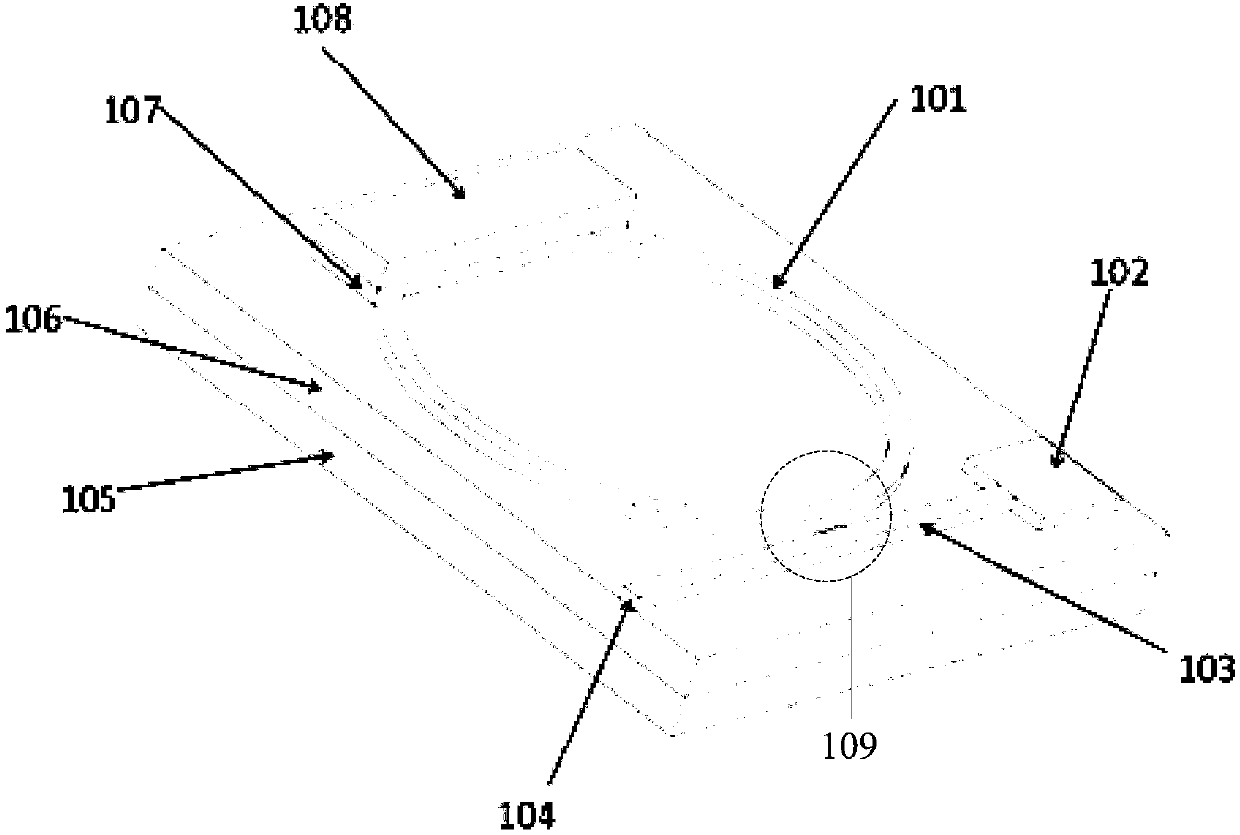

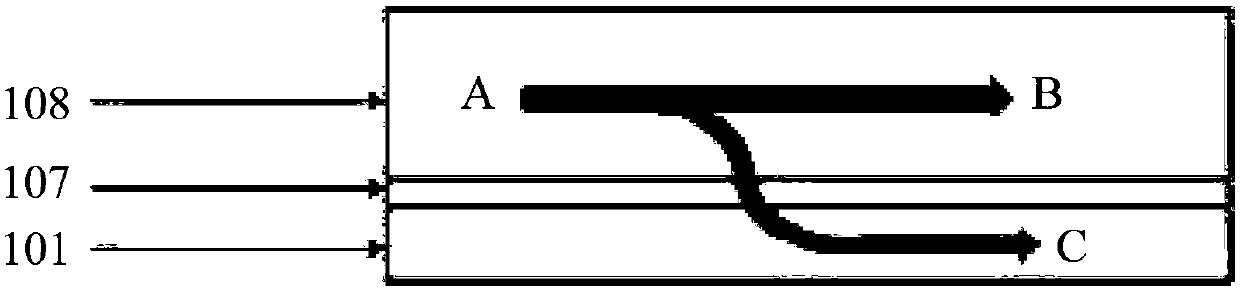

[0051] The resonator 108 is bonded directly above the waveguide of the silicon-based microring resonator 101 through a polymer 107; image 3 As shown, where the optical signal generated by the active region of the resonator 108 is coupled into the silicon-based microring resonator 101 based on the evanescent wave, that is, the optical signal A generated by the active region in the figure is decomposed into an optical signal...

Embodiment 2

[0070] After providing a silicon-based integrated tunable laser structure as described in Embodiment 1, an embodiment of the present invention also provides a control method for a silicon-based integrated tunable laser structure, specifically, according to the method described in Embodiment 1 Si-based integrated tunable laser structures such as Figure 7As shown, the package is completed and the pins 403 (TEC+), 404 (TEC-), 405 (LD+), 406 (LD-), 407 (MPD+) and 408 (MPD- ), and lead out the output polarization maintaining fiber 409, wherein, the control chip 402 connects and controls one or more silicon-based integrated tunable laser packages, such as Figure 8 As shown, the control methods include:

[0071] In step 201, the control circuit 402 receives light from the i-th channel, and the center frequency of the light is λ set Optical power is P set The command.

[0072] In step 202, the control circuit 402 according to the λ set Set the voltage of the Nth channel TEC to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com