Method using cooling crystallization method to increase whiteness of bisphenol AF

A cooling crystallization and bisphenol technology, applied in the field of cooling crystallization to improve the whiteness of bisphenol AF, can solve the problems of yellowing, unsatisfactory whiteness, affecting product quality, etc., and achieve the effect of improving whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

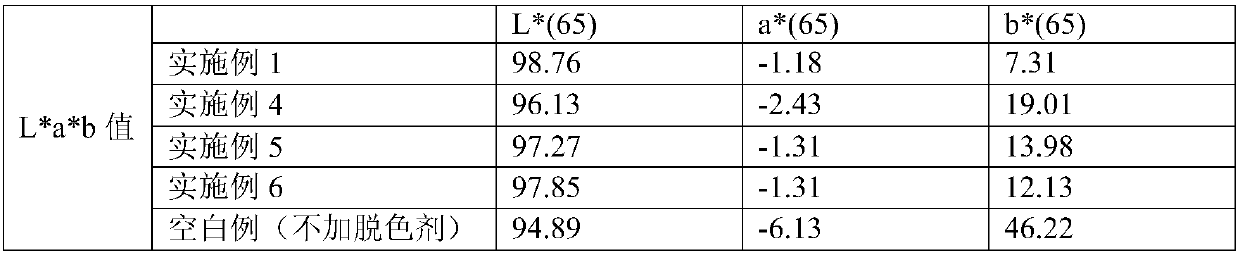

Examples

Embodiment 1

[0025] A kind of cooling crystallization method improves the method for bisphenol AF whiteness, comprises the following steps:

[0026] 1) Add 2400 parts by weight of anhydrous methanol, 1200 parts by weight of crude bisphenol AF and 12 parts by weight of tartaric acid to the reactor in sequence, and stir (stirring speed is 500 r / min).

[0027] 2) Raise the temperature, control the temperature in the reactor at 65°C, and age for 60 minutes.

[0028] 3) After the bisphenol AF crude product is completely dissolved, the temperature is naturally lowered to 52°C to produce crystals, and the crystals are grown for 30 minutes. Then, the frozen brine inlet valve of the reactor is opened and the temperature is lowered to 10°C at a cooling rate of 15°C / h.

[0029] 4) The obtained crystals are filtered, rinsed and dried. Wherein, the crystals are rinsed with anhydrous methanol first, and then washed with water.

[0030] 5) Repeat step 1) to step 4) cooling and crystallizing once to obt...

Embodiment 2

[0032] A kind of cooling crystallization method improves the method for bisphenol AF whiteness, comprises the following steps:

[0033] 1) Add 2000 parts by weight of anhydrous methanol, 1100 parts by weight of crude bisphenol AF and 10 parts by weight of tartaric acid to the reactor in sequence, and stir (stirring speed is 450 r / min).

[0034] 2) Raise the temperature, control the temperature in the reactor at 63° C., and age for 70 minutes.

[0035] 3) After the bisphenol AF crude product is completely dissolved, the temperature is naturally lowered to 50°C to produce crystals, and the crystals are grown for 35 minutes, then the frozen brine inlet valve of the reactor is opened, and the temperature is lowered to 8°C at a cooling rate of 13°C / h.

[0036] 4) The obtained crystals are filtered, rinsed and dried. Wherein, the crystals are rinsed with anhydrous methanol first, and then washed with water.

[0037] 5) Repeat step 1) to step 4) cooling and crystallizing once to ob...

Embodiment 3

[0039] A kind of cooling crystallization method improves the method for bisphenol AF whiteness, comprises the following steps:

[0040] 1) Add 2800 parts by weight of anhydrous methanol, 1300 parts by weight of crude bisphenol AF and 14 parts by weight of tartaric acid to the reactor in sequence, and stir (stirring speed is 550 r / min).

[0041] 2) Raise the temperature, control the temperature in the reactor at 67° C., and age for 50 minutes.

[0042] 3) After the bisphenol AF crude product is completely dissolved, the temperature is naturally lowered to 54°C to produce crystals, and the crystals are grown for 25 minutes. Open the frozen brine inlet valve of the reactor and cool down to 12°C at a cooling rate of 17°C / h.

[0043] 4) The obtained crystals are filtered, rinsed and dried. Wherein, the crystals are rinsed with anhydrous methanol first, and then washed with water.

[0044] 5) Repeat step 1) to step 4) cooling and crystallizing once to obtain a finished product. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com