A kind of preparation method of nanometer yttrium stabilized zirconia powder

A technology of yttrium-stabilized zirconia and powder, which is applied in the field of ceramics. It can solve the problems of affecting the toughness and strength of zirconia ceramics, low shrinkage rate of zirconia powder, and difficult to meet the application of ceramics, so as to prevent agglomeration and high sintering shrinkage rate. , the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

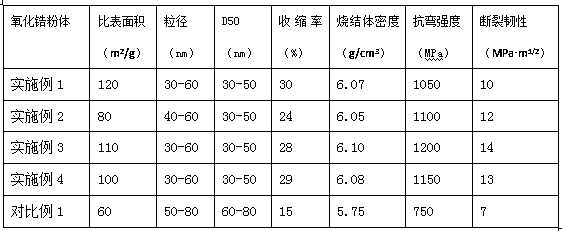

Examples

Embodiment 1

[0024] A preparation method of nano-yttrium stabilized zirconia powder, comprising the following steps:

[0025] (1) Mix zirconium oxychloride, yttrium oxide, and deionized water at a mass ratio of 50:0.8:12, heat to 90°C, and keep warm for 3 hours to obtain a mixed solution;

[0026] (2) Add gum arabic of 10% by mass of the mixed solution obtained in step (1) to the mixed solution obtained in step (1), and then add ethylenediaminetetraacetic acid of 0.1% by mass of the mixed solution obtained in step (1), and stir for 3 hours, Generate a colloidal solution;

[0027] (3) Add an ammonia solution with a mass concentration of 0.5% to the colloidal solution formed in step (2) and stir at the same time, stir for 8 hours until PH=10.0-11.0, a white precipitate is formed, and then stand and age for 24 hours;

[0028] (4) The white precipitate was washed with deionized water, filtered, and then spray-dried at 85°C, the drying temperature was 80°C, and then jet-pulverized to obtain th...

Embodiment 2

[0032] A preparation method of nano-yttrium stabilized zirconia powder, comprising the following steps:

[0033] (1) Mix zirconium oxychloride, yttrium oxide, and deionized water in a mass ratio of 60:1:11, heat to 110°C, and keep warm for 1 hour to obtain a mixed solution;

[0034] (2) Add gum arabic of 5% mass of the mixed solution obtained in step (1) to the mixed solution obtained in step (1), and then add citric acid of 3.0% mass of the mixed solution obtained in step (1), stir for 5 hours to form a colloidal solution ;

[0035] (3) Add an ammonia solution with a mass concentration of 3% to the colloidal solution formed in step (2) and stir at the same time, stir for 10 hours until PH=10.0-11.0, a white precipitate is formed, and then stand and age for 48 hours;

[0036] (4) The white precipitate was washed with deionized water, filtered, and then spray-dried at 90°C at a drying temperature of 100°C, and then air-jet pulverized to obtain the precursor powder;

[0037] (...

Embodiment 3

[0040] A preparation method of nano-yttrium stabilized zirconia powder, comprising the following steps:

[0041] (1) Mix zirconium oxychloride, yttrium oxide, and deionized water at a mass ratio of 55:0.9:10, heat to 100°C, and keep warm for 2 hours to obtain a mixed solution;

[0042] (2) Add 8% gum arabic of the mixed solution obtained in step (1) to the mixed solution obtained in step (1), and then add 0.5% ethylenediaminetetraacetic acid and 1.0% of the mixed solution obtained in step (1) Citric acid, stirred for 4h to generate a colloidal solution;

[0043] (3) Add ammonia solution with a mass concentration of 1% to the colloidal solution formed in step (2) and stir at the same time, stir for 9 hours until PH=10.0-11.0, a white precipitate is formed, and then stand and age for 35 hours;

[0044] (4) The white precipitate was washed with deionized water, filtered, and then spray-dried at 95°C at a drying temperature of 90°C, and then air-jet pulverized to obtain the precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com