Method for deep reduction of remaining active sludge

A technology of residual activity and sludge, which is applied in biological sludge treatment, pyrolysis sludge treatment, sludge treatment through temperature control, etc. It can reduce the amount of excess activated sludge and the treatment cost, and overcome the complicated sludge cracking process and low treatment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The characteristics of the remaining activated sludge to be treated: 10kg of sludge in the sludge thickening tank of a sewage treatment plant biochemical treatment process, the sludge index is: the concentration of mixed suspended solids (MLSS) is 28.7g / L, the concentration of volatile suspended solids in the mixed solution (MLVSS) is 22.4g / L.

[0054] The above-mentioned residual activated sludge to be treated is processed according to the following steps:

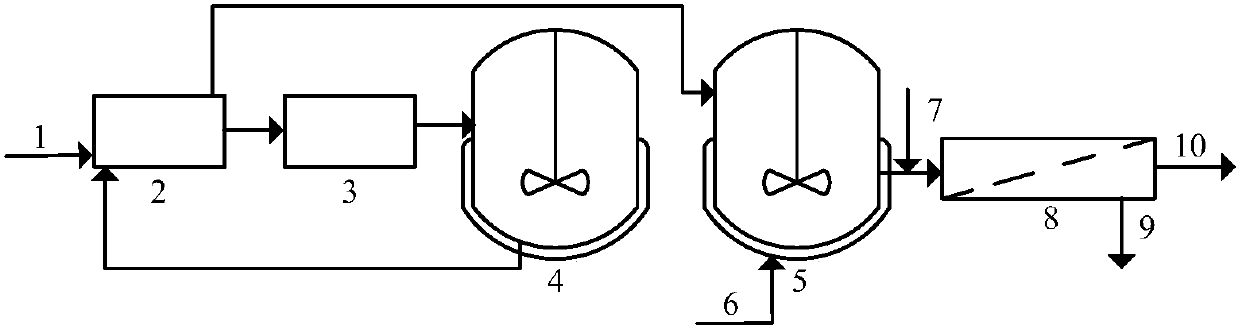

[0055] (1) The remaining activated sludge 1 to be treated is first sent to the heat exchanger 2 to be preheated to a certain temperature, and then sent to the heater 3 to be heated to 75° C. to obtain the heated remaining activated sludge;

[0056](2) Pump the remaining activated sludge after heating into the low-temperature thermal hydrolysis reaction kettle 4, heat and keep it warm with steam; the temperature of the low-temperature thermal hydrolysis reaction kettle 4 is 75° C., and the low-temperature thermal hy...

Embodiment 2

[0071] The characteristics of the remaining activated sludge to be treated: 10kg of sludge in the sludge thickening tank of a sewage treatment plant biochemical treatment process, the sludge index is: the concentration of mixed suspended solids (MLSS) is 28.7g / L, the concentration of volatile suspended solids in the mixed solution (MLVSS) is 22.4g / L.

[0072] The above-mentioned remaining activated sludge to be treated is processed according to the following steps:

[0073] (1) The remaining activated sludge 1 to be treated is first sent to the heat exchanger 2 to be preheated to a certain temperature, and then sent to the heater 3 to be heated to 95° C. to obtain the heated remaining activated sludge;

[0074] (2) Pump the remaining activated sludge after heating into the low-temperature thermal hydrolysis reaction kettle 4, heat and keep it warm with steam; the temperature of the low-temperature thermal hydrolysis reaction kettle 4 is 95° C., and the low-temperature thermal ...

Embodiment 3

[0089] The characteristics of the remaining activated sludge to be treated: 10kg of sludge in the sludge thickening tank of a sewage treatment plant biochemical treatment process, the sludge index is: the concentration of mixed suspended solids (MLSS) is 28.7g / L, the concentration of volatile suspended solids in the mixed solution (MLVSS) is 22.4g / L.

[0090] The above-mentioned remaining activated sludge to be treated is processed according to the following steps:

[0091] (1) The remaining activated sludge 1 to be treated is first sent to the heat exchanger 2 to be preheated to a certain temperature, and then sent to the heater 3 to be heated to 90° C. to obtain the heated remaining activated sludge;

[0092] (2) Pump the remaining activated sludge after heating into the low-temperature thermal hydrolysis reactor 4, heat and keep it warm with steam; the temperature of the low-temperature thermal hydrolysis reactor 4 is 90° C., and the low-temperature thermal hydrolysis react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com