Method for clean continuous preparation of 2-hydroxy-4-methylthiobutyric acid

A technology of methylthiobutyric acid and hydroxyl group, applied in the field of chemical synthesis, can solve the problems of low atom utilization rate, underutilization, high treatment cost, reduce sales and environmental protection pressure, simplify discharge and treatment steps, ammonia consumption small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

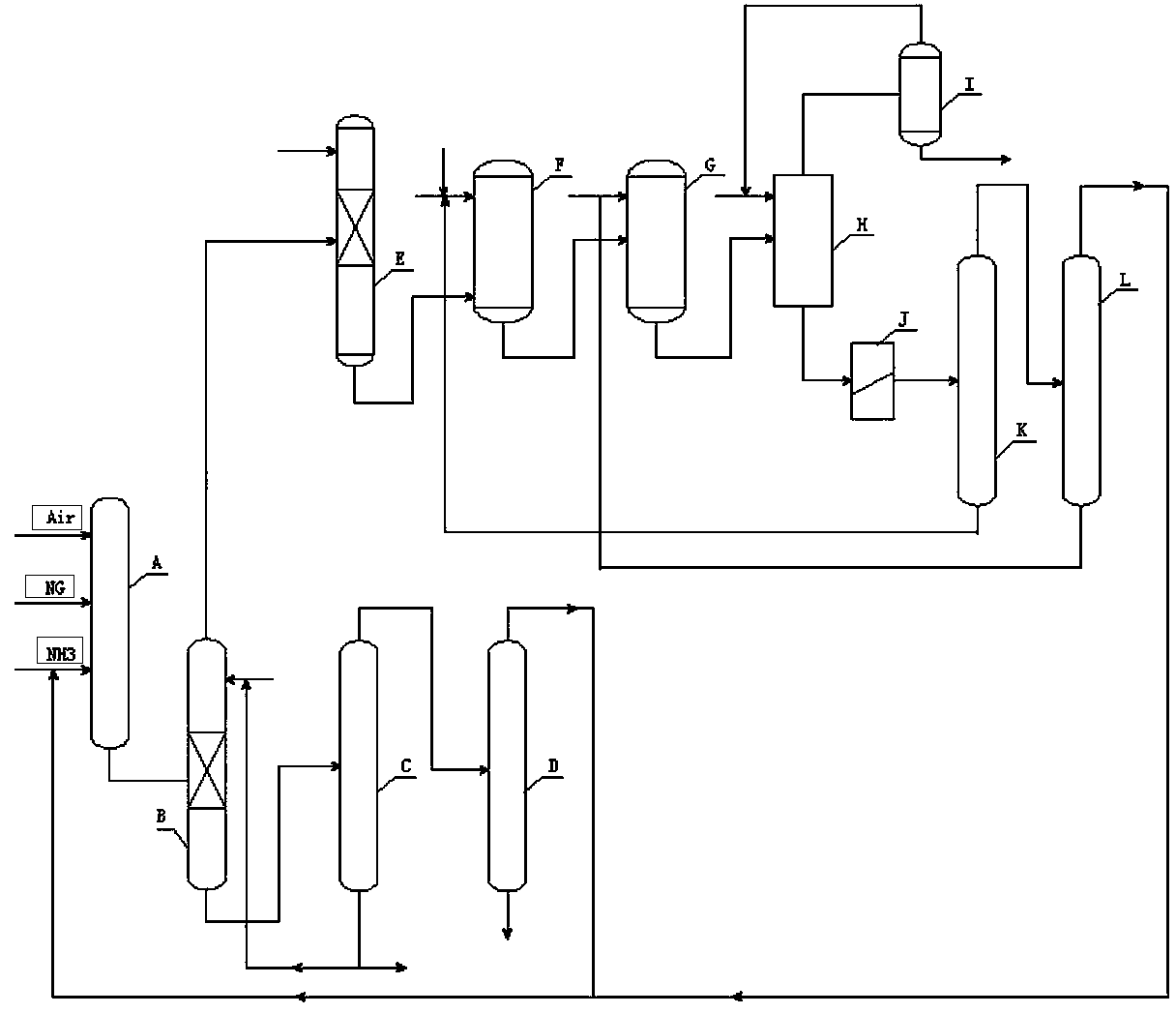

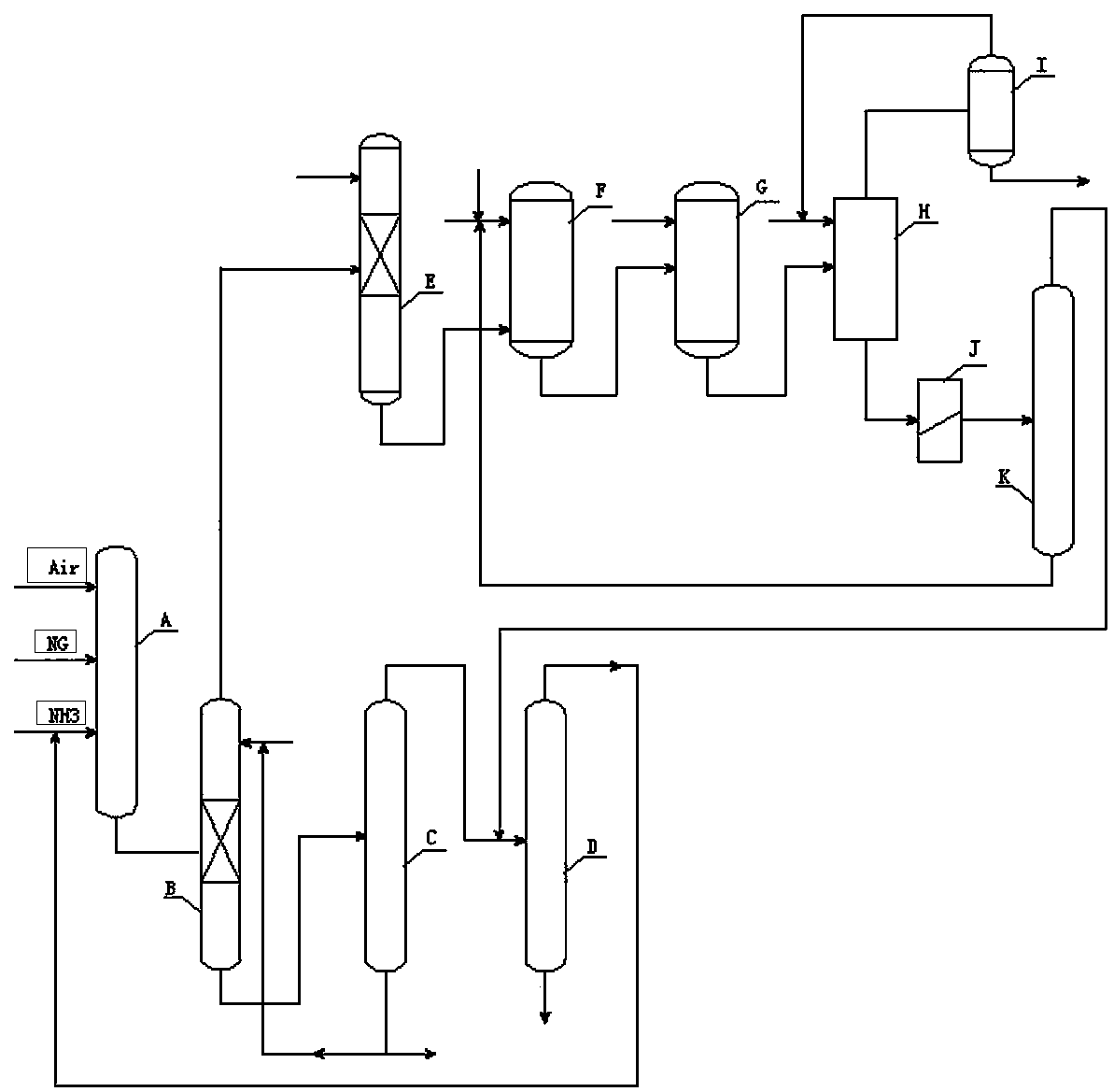

[0068] Example 1 A clean method for the continuous preparation of 2-hydroxy-4-methylthiobutyric acid

[0069] Include the following steps:

[0070] (1) Preparation of hydrocyanic acid

[0071] Step a, prepare the mixed gas I containing prussic acid

[0072] According to the Angle method production process, when the device is started for the first time, the filtered air is mixed at 129.10kg / h and natural gas at 8.78kg / h, and then sent to the feed pipe of hydrocyanic acid reactor A, and at the same time, the feed pipe is passed Inject 9.51kg / h of ammonia gas, the mixed gas of the three enters the hydrocyanic acid reactor A, the reaction temperature is controlled at 1100°C, and the reaction results in 8.51% hydrocyanic acid, 6.87% water, 0.34% ammonia gas, and 0.87% carbon monoxide. Oxygen 1.89%, nitrogen 81.03%, hydrogen 0.5% mixed gas I containing hydrocyanic acid.

[0073] Step b, ammonia neutralization

[0074] Mixed gas I containing hydrocyanic acid is sent to ammonia ne...

Embodiment 2

[0092] Example 2 A clean and continuous method for preparing 2-hydroxy-4-methylthiobutyric acid

[0093] Include the following steps:

[0094] (1) Preparation of hydrocyanic acid

[0095] Step a, prepare the mixed gas I containing prussic acid

[0096] According to the Angle method production process, when the device is started for the first time, the filtered air is mixed at 143.21kg / h and natural gas at 9.74kg / h, and then sent to the feed pipe of hydrocyanic acid reactor A, and at the same time, the feed pipe is passed Inject 10.55kg / h of ammonia gas, the mixed gas of the three enters the hydrocyanic acid reactor A, the reaction temperature is controlled at 1050°C, and the reaction results in 8.86% hydrocyanic acid, 6.67% water, 0.44% ammonia gas, and 0.77% carbon monoxide. Oxygen 1.29%, nitrogen 81.47%, hydrogen 0.5% hydrogen cyanide mixed gas I.

[0097] Step b, ammonia neutralization

[0098] Hydrocyanic acid mixed gas I is sent into ammonia neutralization tower B wit...

Embodiment 3

[0116] Example 3 A clean and continuous method for preparing 2-hydroxy-4-methylthiobutyric acid

[0117] Include the following steps:

[0118] (1) Preparation of hydrocyanic acid

[0119] Step a, prepare the mixed gas I containing prussic acid

[0120] According to the Angle method production process, when the device is started for the first time, the filtered air is mixed at 162.08kg / h and natural gas at 11.03kg / h, and then sent to the feed pipe of hydrocyanic acid reactor A, and at the same time, it is fed into the feed pipe 11.94kg / h of ammonia gas, the mixed gas of the three enters the hydrogen cyanide reactor A, the reaction temperature is controlled at 1000°C, and the reaction contains 8.91% hydrogen cyanide, 6.62% water, 0.42% ammonia, 0.66% carbon monoxide, and oxygen 1.31%, nitrogen 81.68%, hydrogen 0.4% hydrocyanic acid mixed gas I.

[0121] Step b, ammonia neutralization

[0122] Hydrocyanic acid mixed gas I is sent into ammonia neutralization tower B with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com