Synthesis method of clotrimazole

A synthetic method, the technology of clotrimazole, applied in the field of chemical synthesis, can solve the problems of long production cycle, cumbersome operation, and many wastes, and achieve the effect of simple operation, high reactivity, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] A kind of synthetic method of clotrimazole, the steps are as follows:

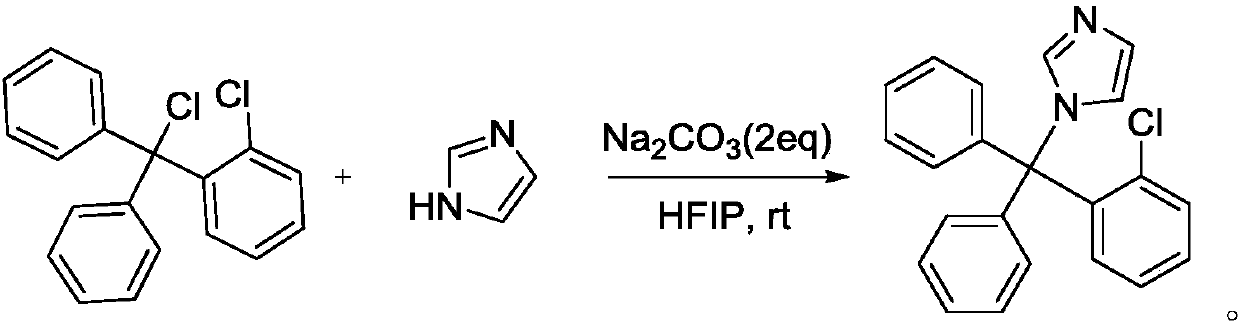

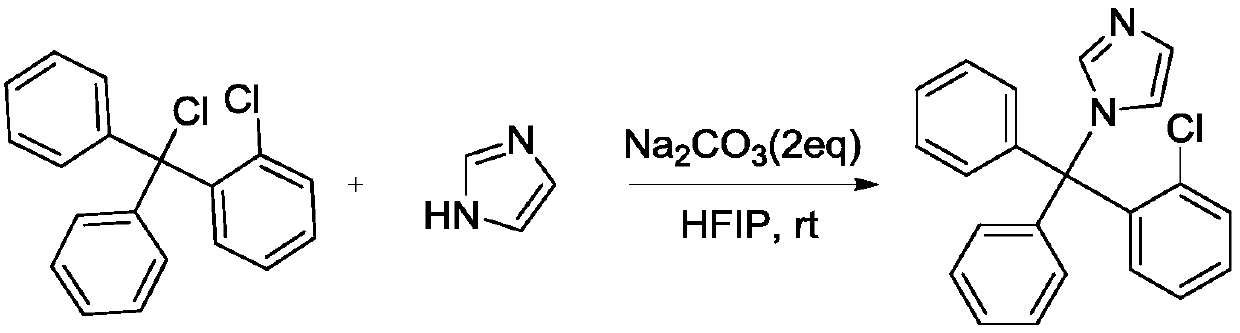

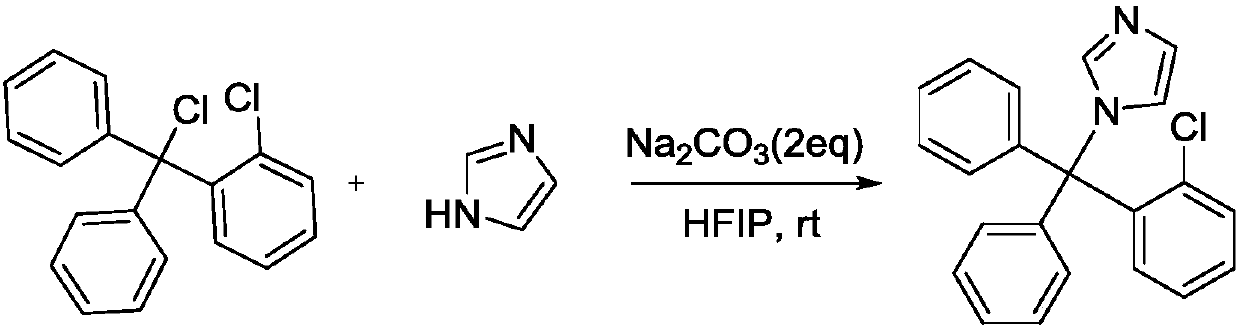

[0022] Take 4mmol of 2-chlorotrityl chloride, 8mmol of imidazole and 8mmol of sodium carbonate, add 20mL of hexafluoroisopropanol (HFIP), and stir at room temperature (25°C) for 48h. The reaction formula is as follows:

[0023]

[0024] After the reaction was completed, the reaction was determined by TLC, concentrated and separated by column chromatography.

[0025] The reaction yield was detected to be 92%.

[0026] The clotrimazole prepared by the embodiment of the present invention 1 was added in deuterated chloroform (CDCl 3 ), carry out nuclear magnetic resonance analysis, the result is as follows:

[0027] 1HNMR (500MHz, CDCl 3 )δ7.46(s,1H),7.41(d,J=7.7Hz,1H),7.34(d,J=1.2Hz,7H),7.24(d,J=8.0Hz,1H),7.20(d , J=1.3Hz, 4H), 7.06(s, 1H), 6.93(d, J=7.8Hz, 1H), 6.75(s, 1H).

[0028] 13CNMR (125MHz, CDCl 3 )δ 140.90, 140.38, 139.13, 135.59, 132.23, 130.42, 130.19, 129.87, 128.43, 128.17, 128....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com