Clay anti-swelling agent for high temperature oil field acidizing

An anti-swelling agent, oil field technology, applied in the direction of organic chemistry, etc., can solve the problem of the clay anti-swelling agent being unsuitable for high temperature acidification environment, and achieve the effects of easy acquisition, transportation and storage, high yield, and good temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: clay antiswelling agent A 1 and its preparation method

[0027] (1) Clay anti-swelling agent A 1 The composition, components and molecular formula are as follows:

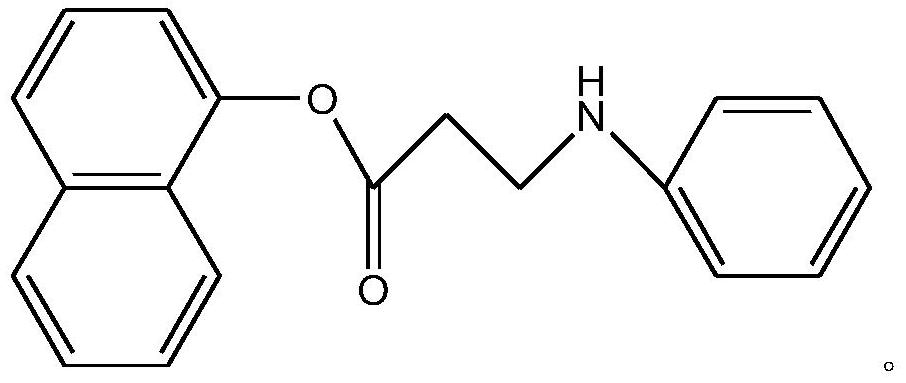

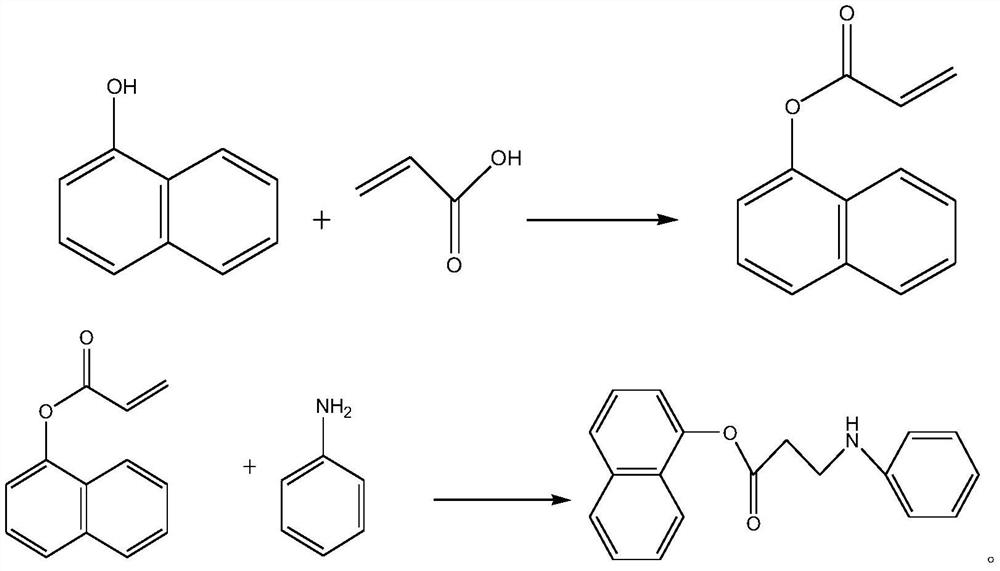

[0028] Clay anti-swelling agent A 1 Naphthol acrylate is produced by reacting 1 mol of 1-naphthol with 0.9 mol of acrylic acid, followed by Michael addition reaction with 1.1 mol of aniline. Its molecular formula is as follows:

[0029]

[0030] (2) Clay anti-swelling agent A 1 The preparation method is as follows:

[0031] ①In a three-necked flask equipped with nitrogen protection, reflux condenser and thermometer, first add 1mol of 1-naphthol and 0.9mol of acrylic acid, heat up to 80°C, and then slowly add 288.34g of sodium hydroxide under the condition of a stirring rate of 200rpm , after the sodium hydroxide is completely added, raise the temperature to 120°C at a rate of 7°C per minute, keep the stirring rate constant, and react at a constant temperature for 2 hours, then turn off...

Embodiment 2

[0036] Embodiment 2: clay antiswelling agent A 2 and its preparation method

[0037] (1) Clay anti-swelling agent A 2 The composition, components and molecular formula are as follows:

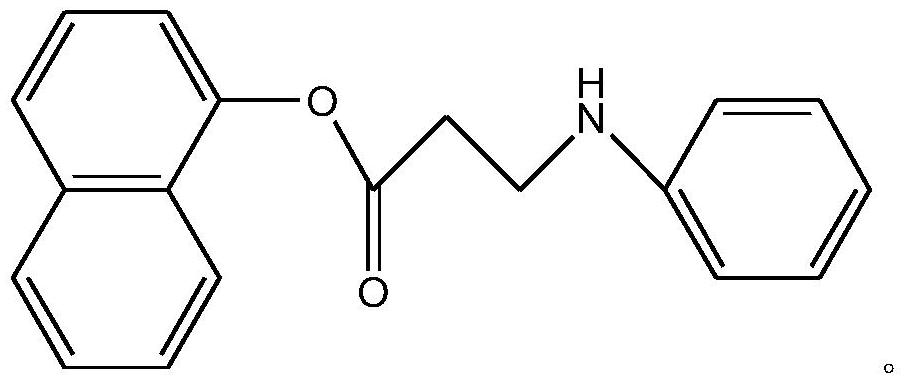

[0038] Clay anti-swelling agent A 2 Naphthol acrylate is produced by reacting 1 mol of 1-naphthol with 1.1 mol of acrylic acid, followed by Michael addition reaction with 1.2 mol of aniline. Its molecular formula is as follows:

[0039]

[0040] (2) Clay anti-swelling agent A 2 The preparation method is as follows:

[0041] ①In a three-necked flask equipped with nitrogen protection, reflux condenser and thermometer, first add 1mol of 1-naphthol and 1.1mol of acrylic acid, raise the temperature to 85°C, and then slowly add 360.43g of sodium hydroxide under the condition of a stirring rate of 320rpm , after the sodium hydroxide is completely added, raise the temperature to 130°C at a rate of 8°C per minute, keep the stirring rate constant, and react at a constant temperature for 5h, then...

Embodiment 3

[0045] Embodiment 3: clay antiswelling agent A 3 and its preparation method

[0046] (1) Clay anti-swelling agent A 3 The composition, components and molecular formula are as follows:

[0047] Clay anti-swelling agent A 3 Naphthyl acrylate is produced by reacting 1 mol of 1-naphthol with 1.5 mol of acrylic acid, followed by Michael addition reaction with 1.3 mol of aniline. Its molecular formula is as follows:

[0048]

[0049] (2) Clay anti-swelling agent A 3 The preparation method is as follows:

[0050] ①In a three-necked flask equipped with nitrogen protection, reflux condenser and thermometer, first add 1mol of 1-naphthol and 1.5mol of acrylic acid, heat up to 90°C, and then slowly add 432.51g of sodium hydroxide under the condition of stirring rate of 400rpm , after the sodium hydroxide is completely added, raise the temperature to 145°C at a rate of 10°C per minute, keep the stirring rate constant, and react at a constant temperature for 8 hours, then turn off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com