A developer and its preparation method and a fingerprint display method

A developer and fingerprint technology, applied in chemical instruments and methods, medical science, diagnosis, etc., to achieve the effects of low production cost, simple operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

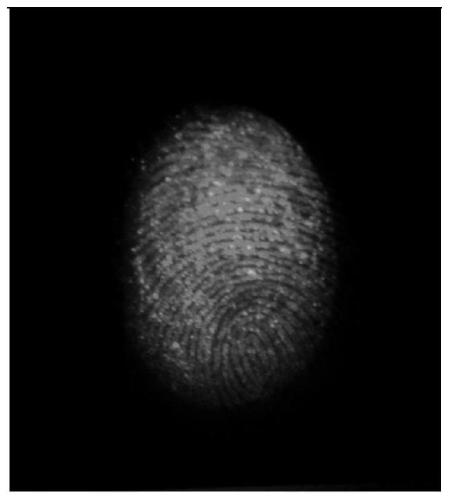

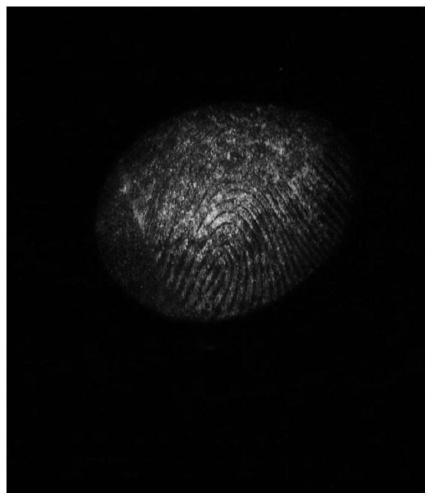

Image

Examples

Embodiment 1

[0026] Weigh 0.5g of the up-conversion fluorescent material. In this embodiment, the up-conversion fluorescent material uses up-conversion fluorescent particles, and the up-conversion fluorescent material is NaYF 4 :Yb 3+ ,Er 3+ , YF 3 :Yb 3+ ,Er 3+ 、NaYF 4 :Yb 3+ ,Tm 3+ , YF 3 :Yb 3+ ,Tm 3+ 、NaYF 4 :Yb 3+ ,Ho 3+ or YF 3 :Yb 3+ ,Ho 3+ At least one of them, in this embodiment, the up-converting fluorescent particles are NaYF 4 :Yb 3+ ,Er 3+ , the particle size of the up-converting fluorescent particles is 0.1-5 μm, and the plasma treatment is carried out under normal pressure for 30 s, and the plasma treatment can be performed by using at least one gas in air, argon, nitrogen or helium for discharge treatment, The plasma processing power is 250W. Take the plasma-treated up-conversion fluorescent material and mix it with 20mL fumigant / inorganic alkali mixed solution, stir at a speed of 3000rpm / min for 5min, and disperse evenly to obtain a developer, wherein th...

Embodiment 2

[0032] Weigh 1.0 g of up-conversion fluorescent material. In this embodiment, the up-conversion fluorescent material uses up-conversion fluorescent particles, and the up-conversion fluorescent particles are YF 3 :Yb 3+ ,Er 3+, the particle size of the up-conversion fluorescent particles is 0.1-5 μm, and the plasma treatment is carried out under normal pressure for 60 s, and the plasma treatment can be performed by discharging at least one gas in air, argon, nitrogen or helium, The plasma processing power is 100W. Take the plasma-treated up-conversion fluorescent material and mix it with 20mL fumigant / inorganic alkali mixed solution, stir at a speed of 5000rpm / min for 5min, and disperse evenly to obtain a developer, wherein the fumigant used contains α-cyanoacrylic acid A mixture of ester compound glue and potassium hydroxide solution, and the concentration of KOH in the fumigant / KOH mixed solution is 10 mg / mL.

[0033] Take the prepared developer and spray it vertically ont...

Embodiment 3

[0035] Weigh 0.5g of the up-conversion fluorescent material. In this embodiment, the up-conversion fluorescent material uses up-conversion fluorescent particles, and the up-conversion fluorescent particles are NaYF 4 :Yb 3+ ,Tm 3+ , the particle size of the up-conversion fluorescent particles is 0.1-5 μm, and the plasma treatment is carried out under normal pressure for 5 s, and the plasma treatment can be performed by using at least one gas in air, argon, nitrogen or helium for discharge treatment, The plasma processing power is 500W. Take the plasma-treated up-conversion fluorescent material and mix it with 20mL fumigant / inorganic alkali mixed solution, stir at a speed of 5000rpm / min for 5min, and disperse evenly to obtain a developer, wherein the fumigant used contains α-cyanoacrylic acid The mixture of the glue of ester compound and sodium carbonate solution, the concentration of sodium carbonate in the described fumigant / sodium carbonate mixed solution is 20mg / mL.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com