Fabrication method of microsphere resonator based on electrohydrodynamic spray printing

The technology of a microsphere resonant cavity and manufacturing method is applied in the field of optical microcavity, which can solve the problems that the size of the microsphere cavity cannot be effectively controlled, the size of the microsphere cavity is small, and the equipment is complicated, and the structure is simple and reliable, the manufacturing efficiency is high, and the use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

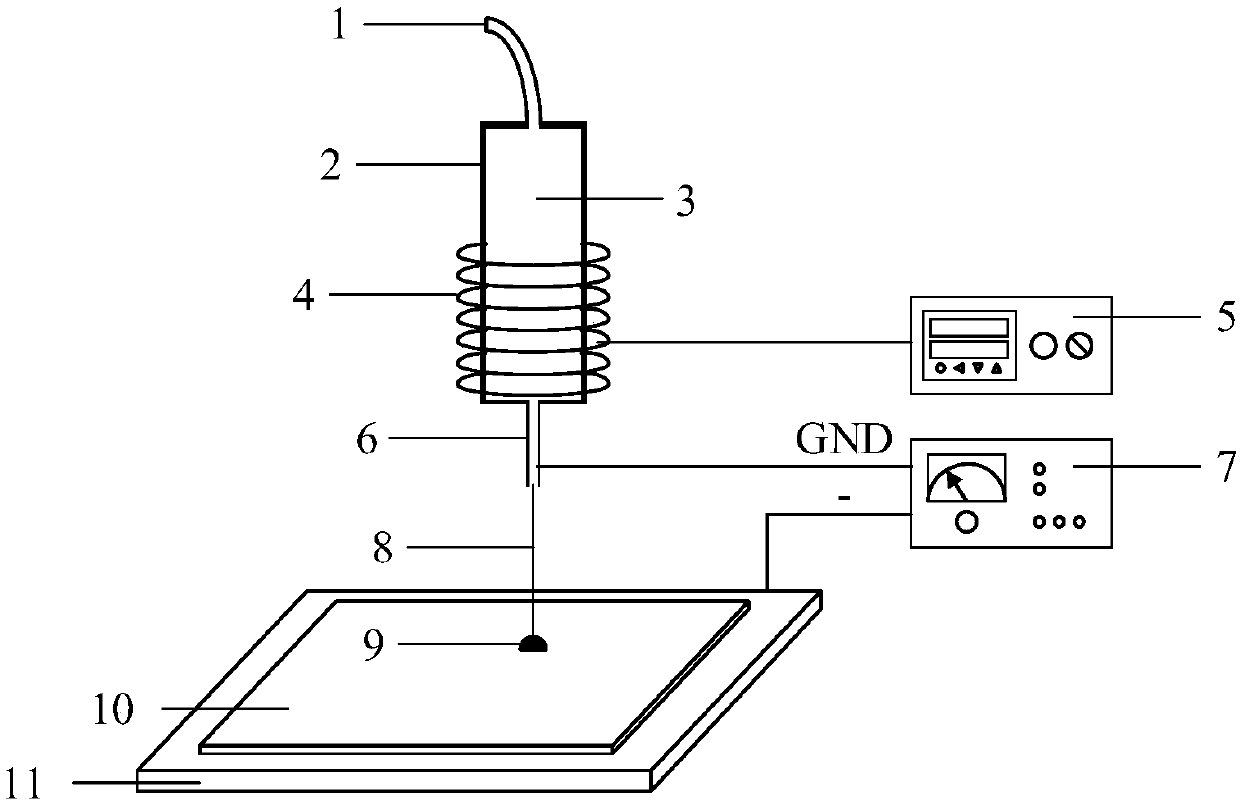

[0019] combine figure 1 and 2 , air pipe 1 is connected with a precision air pump to provide stable internal pressure and small flow rate of molten polymer solution for molten polymer raw material 3 in metal storage pipe 2, metal microchannel 6 nozzles form a hemispherical hanging drop; heater 4 and The metal storage pipe 2 is closely attached, and the temperature of the molten polymer raw material 3 in the storage pipe 2 is adjusted by the temperature controller 5; the nozzle of the metal microchannel 6 is connected to the ground end of the high-voltage power supply 7, and the electrode plate 11 and the high-voltage power supply 7 are under negative pressure end connection, when the high-voltage power supply 7 outputs a specified voltage, the droplets at the nozzles of the metal microchannel 6 are spray-printed onto the collecting plate 10 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com