Two-dimensional black phosphorus pn junction, its preparation method and application

A PN junction and black phosphorus technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of complex process, low yield, and low efficiency, and achieve the effect of good repeatability and simple and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

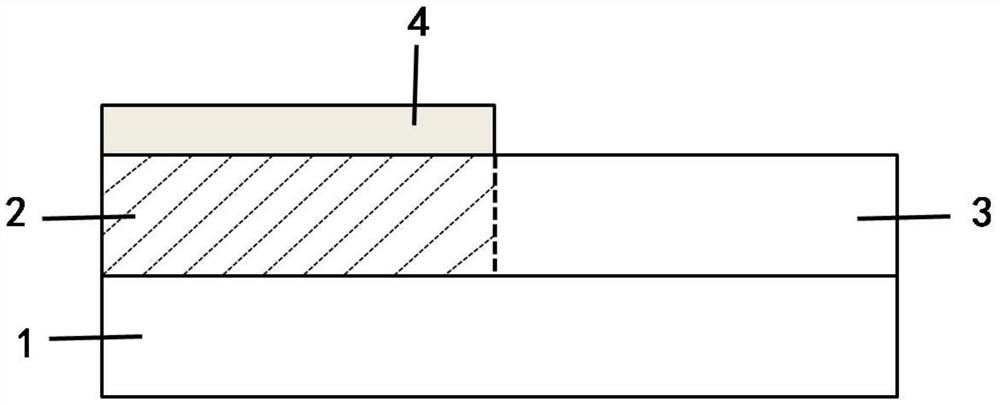

[0035] The embodiment of the present invention also provides a method for preparing a two-dimensional black phosphorus PN junction, which includes:

[0036] Provide two-dimensional black phosphorus film;

[0037] Perform n-type doping to a local area of the black phosphorus film to form an n-type semiconductor, while keeping other local areas of the black phosphorus film as a p-type semiconductor, and make the n-type semiconductor cooperate with the p-type semiconductor to form a PN semiconductor. Knot.

[0038] In some embodiments, the preparation method includes: at least selecting a physical and / or chemical deposition method to deposit a film with charge transfer doping properties on a local area of the black phosphorus film surface, so that the local black phosphorus film The region is n-type doped to form an n-type semiconductor.

[0039] Furthermore, the constituent substances of the film with charge-transfer doping properties deposited on the surface of the black ...

Embodiment 1

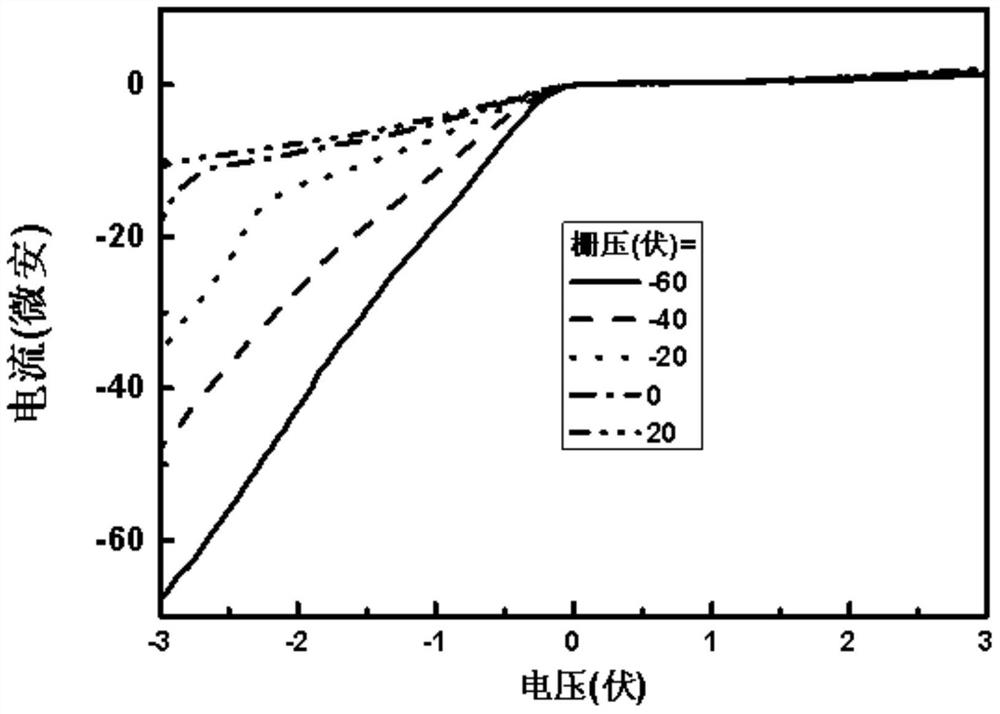

[0049] Example 1: A black phosphorus film with a thickness of 5 to 20 nanometers is obtained by exfoliating black phosphorus crystals using a micromechanical exfoliation method or a liquid phase exfoliation method, and transferring the black phosphorus film to a substrate, which includes but is not limited to Silicon wafer, quartz, silicon oxide, silicon carbide, aluminum oxide, PET, etc. Further, a layer of Si is deposited on the local surface of the black phosphorus film x N y Thin film, the deposition method includes PECVD, ICPCVD, LPCVD or thermal evaporation, etc., the silicon source gas used in the deposition method includes SiN 4 、SiF 4 、SiCl 3 H, SiCl 4 、SiH 2 Cl 2 Any one or a combination of two or more of them, but not limited thereto. The nitrogen source gas used in the deposition method includes N 2 O, N 2 , NH 3 Any one or a combination of two or more of them, but not limited thereto. Further, the volume ratio of silicon source gas to nitrogen source ga...

Embodiment 2

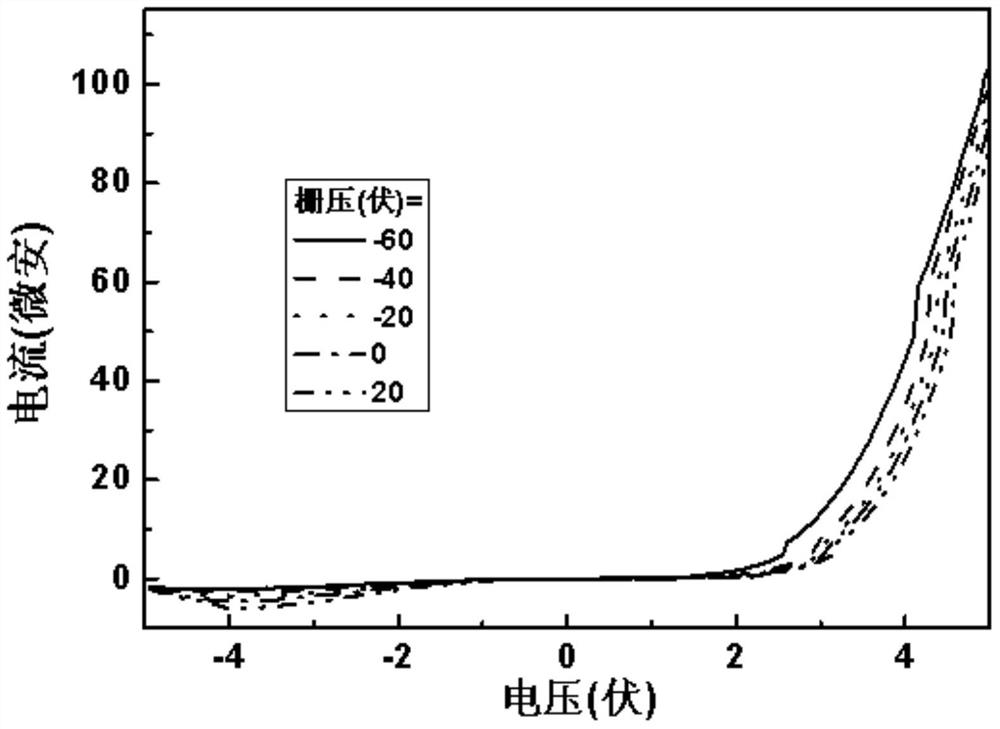

[0054] Embodiment 2: Use the micromechanical stripping method or the liquid phase stripping method to obtain a black phosphorus film with a thickness of 40 to 60 nanometers from the black phosphorus crystal, transfer the film to a silicon substrate, and then use the method of spin coating on the black phosphorus surface A layer of 1,5-naphthalene diamine thin film is deposited in a local area, and the film thickness is 1000-2000 nanometers. It is found by testing the electrical properties that the two-dimensional black phosphorus PN junction samples obtained in this embodiment also have obvious unidirectional conductivity. For example, the test results of a typical black phosphorus PN junction sample can be found in image 3 . These black phosphorus PN junctions are suitable for making rectifier diodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com