Composite fruit juice made from blueberries and bananas and making method of composite fruit juice

A compound fruit juice and production method technology, applied in the direction of food science, etc., can solve the problems of high waste residue rate, obvious astringent taste, low juice yield, etc., and achieve the effects of reducing waste residue rate, attractive color and eliminating astringency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 (selection of pectinase)

[0028] This embodiment includes the following steps:

[0029] (1) Select single-frozen blueberries that are plump, free from pests and diseases, mechanical damage, and impurities (including leaves and stems). Thaw 1,000g of imported wild blueberries and 500g of domestically grown blueberries, thaw, mix and beat evenly.

[0030] (2) Take 0.045g of pectinase and 0.015g of cellulase, add 1.2ml of 45°C water, activate for 20 minutes, add the above-mentioned blueberry puree, stir well, put it in a water bath at 45°C for 1 hour, and then put it in boiling water Inactivate the enzyme in the bath under normal pressure for 20 minutes.

[0031] (3) Use a 60-mesh filter sieve to filter the blueberry puree after deactivating the enzyme to obtain blueberry pulp.

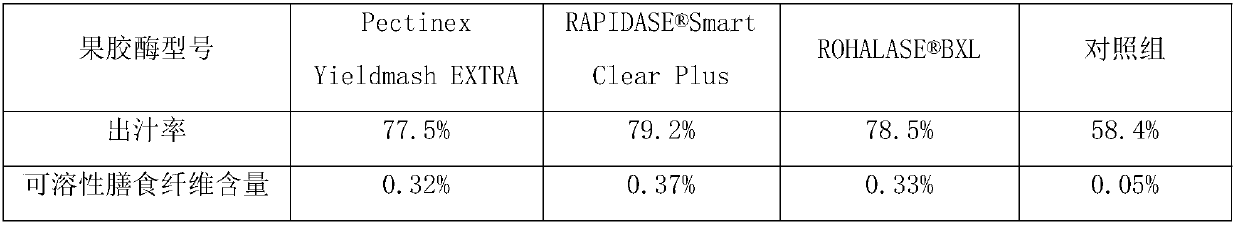

[0032] In the present embodiment, three kinds of pectinases are selected for comparative experiments, and the above steps are carried out respectively, and the juice yield and the ...

Embodiment 2

[0037] This embodiment includes the following steps:

[0038] (1) 300g banana pulp, thawed and set aside.

[0039] (2) Select single-frozen blueberries that are plump, free from pests and diseases, mechanical damage, and impurities (including leaves and stems). Thaw 1000g of imported wild blueberries and 500g of domestically grown blueberries, thaw, mix and beat evenly.

[0040] (3) Mix 0.045g of pectinase with 0.015g of cellulase, add 1.2ml of 45°C water, activate for 20 minutes, add the above-mentioned 1458g of blueberry puree, stir well, and place in a water bath at 45°C for 1.5h of enzymolysis. Then place it in a boiling water bath for 20 minutes to inactivate the enzyme under normal pressure.

[0041] (4) Filter the blueberry puree after enzymolysis with a 60-mesh filter sieve to obtain 1193 g of blueberry pulp.

[0042] (5) Mix blueberry pulp and banana pulp at a mass ratio of 3:1 to obtain 1200 g of a mixed solution, place it in a homogenizer and homogenize for 8 minu...

Embodiment 3

[0050] This embodiment includes the following steps:

[0051] (1) 400g banana pulp, thawed and set aside.

[0052] (2) Select single-frozen blueberries that are plump, free from pests and diseases, mechanical damage, and impurities (including leaves and stalks). Thaw 1200g of imported wild blueberries and 400g of domestically grown blueberries, mix and beat evenly.

[0053] (3) Mix 0.048g of pectinase with 0.016g of cellulase, add 1.9ml of 50°C water, activate for 20 minutes, add the above-mentioned 1556g of blueberry puree, stir well, place in a water bath at 50°C for 1.0h of enzymolysis, Then place it in a boiling water bath for 20 minutes to inactivate the enzyme under normal pressure.

[0054] (4) Filter the blueberry puree after enzymolysis with a 40-mesh filter sieve to obtain 1261 g of blueberry pulp.

[0055] (5) Mix the blueberry pulp and banana pulp in a mass ratio of 2:1 to obtain 1200 g of the mixed solution, place it in a homogenizer and homogenize it under a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com