Composite flue gas denitrification oxidizing agent and application method of composite flue gas denitrification oxidizing agent

An oxidant and denitrification technology, applied in the field of flue gas denitrification agent, can solve the problem of oxidant to be further developed, and achieve the effects of low equipment investment and maintenance costs, high denitration efficiency and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

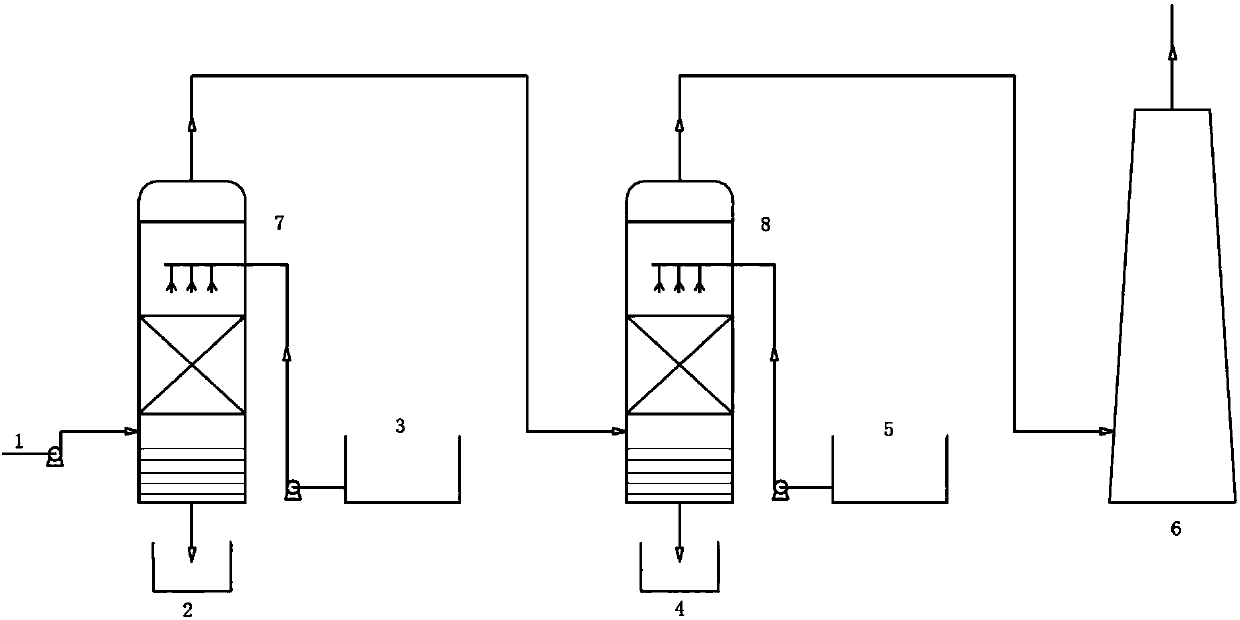

[0017] Embodiment 1: Potassium persulfate complex (2KHSO 5 ·KHSO 4 ·K 2 SO 4 ), trichloroisocyanuric acid and sodium hypochlorite mixed solution to oxidize NO and Na 2 CO 3 Alkaline solution absorption denitrification

[0018] The flue gas containing NOx after pre-dust removal and desulfurization treatment is sent from the bottom of the oxidation absorption tower by a fan, and 0.5wt% potassium hydrogen persulfate compound (2KHSO 5 ·KHSO 4 ·K 2 SO 4 ), 1wt% trichloroisocyanuric acid and 3wt% sodium hypochlorite solution to oxidize NO. The oxidized flue gas is sent to the bottom of the alkaline absorption tower through the fan, and the 2 CO 3 Alkaline solution absorption. Contains NO x The residence time of the gas in the oxidation absorption tower and the alkaline absorption tower is 8s and 10s respectively, the operating temperature of the oxidation absorption tower is 60°C and the liquid-gas ratio is 10L / m 3 , the liquid-gas ratio of the alkaline absorption tower...

Embodiment 2

[0019] Embodiment 2: trichloroisocyanuric acid and sodium hypochlorite mixed solution oxidation NO and Na 2 CO 3 Alkaline solution absorption denitrification

[0020] The NOx-containing flue gas that has been pre-dusted and desulfurized is sent from the bottom of the oxidation absorption tower by a fan, and the NO is oxidized by using 1wt% trichloroisocyanuric acid and 10wt% sodium hypochlorite solution. The oxidized flue gas is sent to the bottom of the alkaline absorption tower through the blower fan, and the 15wt% Na 2 CO 3 Alkaline solution absorption. Contains NO x The residence time of the gas in the oxidation absorption tower and alkaline absorption tower is 10s and 15s respectively, the operating temperature of the oxidation absorption tower is 50°C and the liquid-gas ratio is 10L / m 3 , the liquid-gas ratio of the alkaline absorption tower is 20L / m 3 . The final denitrification efficiency can reach 96%.

Embodiment 3

[0021] Embodiment 3: Potassium persulfate complex (2KHSO 5 ·KHSO 4 ·K 2 SO 4 ) and trichloroisocyanuric acid mixed solution to oxidize NO and Na 2 CO 3 Alkaline solution absorption denitrification

[0022] Will be pre-dusted and desulfurized to contain NO x The flue gas is sent from the bottom of the oxidation absorption tower by the fan, and 2wt% potassium hydrogen persulfate compound (2KHSO 5 ·KHSO 4 ·K 2 SO 4 ) and 1wt% trichloroisocyanuric acid solution to oxidize NO. The oxidized flue gas is sent to the bottom of the alkaline absorption tower through the blower fan, and the 20wt% Na 2 CO 3 Alkaline solution absorption. Contains NO x The residence time of the gas in the oxidation absorption tower and the alkaline absorption tower is 5s and 10s respectively, and the operating temperature of the oxidation absorption tower is 45°C and the liquid-gas ratio is 5L / m 3 , the liquid-gas ratio of the alkaline absorption tower is 15L / m 3 . The final denitrification e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Denitrification efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap