Low-GI biscuits as well as preparation method and application thereof

A biscuit and edible oil technology, applied in the field of low GI biscuits and its preparation, to achieve the effect of rich flavor, crispy and crisp taste, and low GI value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In addition, the embodiment of the present invention also provides a method for preparing the above-mentioned low GI biscuit, for example, may include the following steps: mixing mung bean flour and soybean flour to obtain a first mixture. Dissolve edible oil, maltitol and improver to obtain the second mixture. The first mixture, the second mixture and the remaining raw materials are mixed, then stirred, matured, calendered and shaped to obtain biscuit embryos. Bake the biscuit embryos to get low GI biscuits. Among them, mung bean powder and soybean powder can be directly cooked powder, and when they are uncooked powder, they can be fried first. By frying the mung bean powder and soybean powder until cooked, on the one hand, the baking time of the biscuit can be shortened, and on the other hand, the fragrance of the biscuit can be enhanced.

[0044] Preferably, when the flavor ingredients include milk powder, seaweed powder, eggs and green onions, the eggs, edible oil...

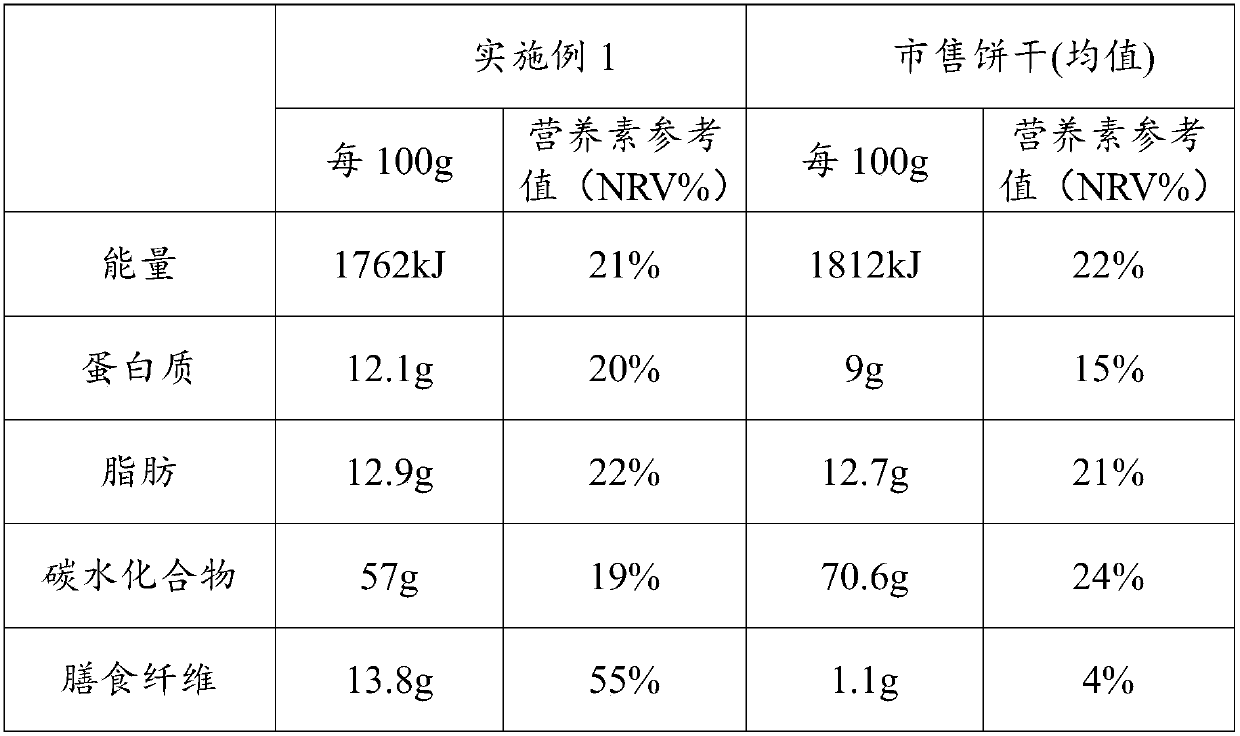

Embodiment 1

[0056] Fry 4 parts by weight of mung bean powder and 1 part by weight of soybean powder to obtain the first mixture. Eggs, 7 parts by weight of palm oil, 18 parts by weight of maltitol with a dry matter content of 55%, and 0.1 part by weight of an improving agent were dissolved in water to obtain a second mixture. The above-mentioned first mixture is mixed with 30 parts by weight of flour, 1 part by weight of resistant dextrin, 0.1 part by weight of celery powder, 9 parts by weight of wheat fiber powder, 9 parts by weight of buckwheat flour, 1 part by weight of tartary buckwheat powder and After the konjac powder of 1 weight part is mixed, sieved, then mixes with above-mentioned second mixture.

[0057] Improvers include table salt, carbamide, baking soda, ethyl maltol, terpineol, and milk flavoring. The flavor raw materials include milk powder, seaweed powder, eggs and green onions, and the flavor raw materials are 0.1 parts by weight in total.

[0058] Then stir at a rotat...

Embodiment 2

[0061] Fry 13 parts by weight of mung bean powder and 4 parts by weight of soybean powder to obtain the first mixture. Eggs, 15 parts by weight of palm oil, 25 parts by weight of maltitol with a dry matter content of 65%, and 3 parts by weight of an improving agent were dissolved in water to obtain a second mixture. The above-mentioned first mixture is mixed with 35 parts by weight of flour, 3 parts by weight of resistant dextrin, 3 parts by weight of celery powder, 13 parts by weight of wheat fiber powder, 13 parts by weight of buckwheat flour, 4 parts by weight of tartary buckwheat powder and 3 parts by weight of konjac flour are mixed, sieved, and then mixed with the above-mentioned second mixture.

[0062] Improvers include table salt, carbamide, baking soda, ethyl maltol, terpineol, and milk flavoring. The flavor raw materials include milk powder, seaweed powder, eggs and green onions, and the flavor raw materials total 5 parts by weight.

[0063] Then stir at a rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com