Micro-cathode electric arc thruster

A cathodic arc and cathode technology, which is applied in thrust reversers, machines/engines, propulsion systems for space vehicles, etc., can solve the problems of inconvenient integration of micro-nano satellite operating systems, safety to be further improved, and high plasma energy consumption. , to achieve the effect of easy quantitative production, simple structure and high pulse stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

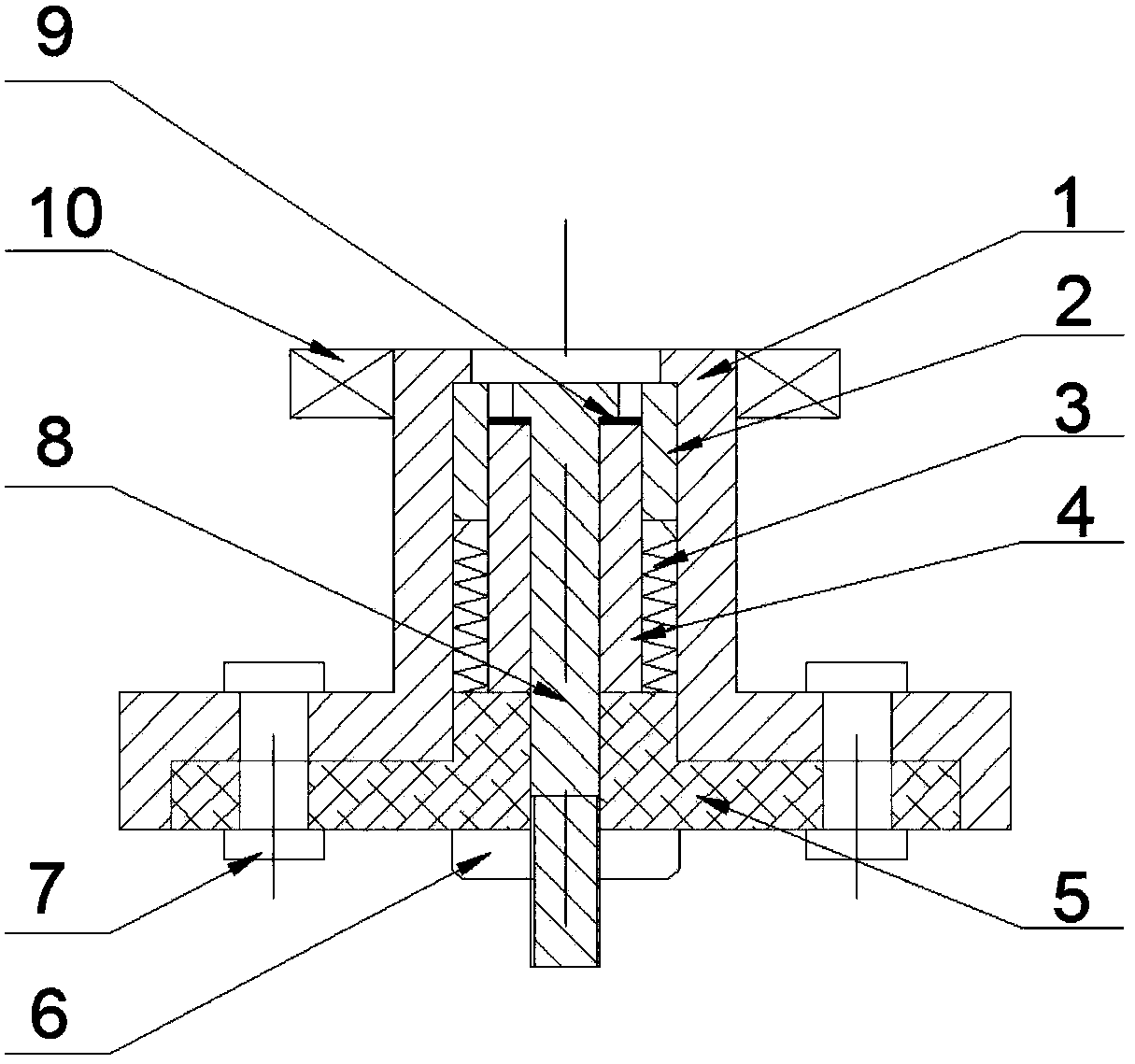

[0036] Embodiment 1 A kind of micro-cathode arc thruster

[0037] refer to figure 1 and 2 As shown, the micro-cathode arc thruster is a tubular annular structure as a whole, wherein the shell 1 and the base 5 are connected to form a semi-closed cylindrical structure; the ceramic cylinder 4 is arranged in the semi-closed cylindrical structure, and the base 5 ceramic cylinder 4 An insulating structure is formed to isolate the anode and cathode; the cathode working medium 2 is connected to the casing 1 to form a cathode path, together with the anode 8 and the conductive coating layer 9 set on the top of the ceramic cylinder 4 form a complete conductive circuit, the conductive coating layer 9 is before arcing Flow resistance, access in working state; spring 3 is placed at the lower end of cathode 2, and the lower end of spring 3 is connected to base 5, and the working medium propulsion system is mainly completed by spring 3; the connection between cathode working medium 2 and she...

Embodiment 2

[0038] Embodiment 2 A kind of micro-cathode arc thruster

[0039] refer to figure 1 and 2 As shown, on the basis of Example 1, the cathode working medium 2 is in the shape of a circular through-hole, which doubles as a propellant working medium, and its material can be conductive metal materials such as copper, nickel, and titanium.

[0040] The conductive coating layer 9 is coated on the side of the ceramic cylinder 4 close to the magnetic coil 10 and is in the shape of a ring. The conductive coating layer can be a functional conductive film layer such as titanium nitride, carbon, or titanium carbide nitride.

[0041] The base 5 is in the shape of a cylindrical boss, and the upper part cooperates with the inner hole of the shell 1. It adopts insulating materials such as Teflon, and is combined with the shell to close the internal structure. The middle hole is used for the anode rod 8 to pass through.

[0042] The anode 8 is rod-shaped, and the outer diameter of the upper bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com